Composition for adjusting wet building materials and building materials

A technology for composition and building materials, which is applied in the field of moisture-regulating building materials and humidity-regulating building materials, and can solve the problems of difficulty in obtaining both strength and humidity-regulating properties of humidity-regulating building materials, difficulty in maintaining shape, and large volume changes, etc., to achieve full absorption and release Excellent wet properties, strength, and excellent shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

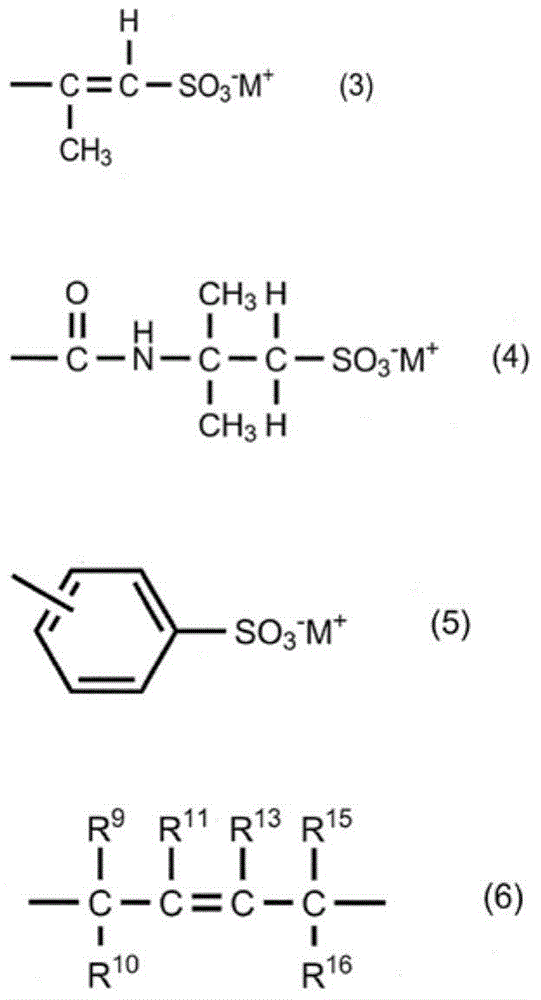

[0105] A monomer aqueous solution was prepared by mixing 301 parts of a 40% aqueous solution of isoprenesulfonic acid sodium salt, 141 parts of an 80% aqueous solution of acrylic acid, and 102 parts of a 20% aqueous solution of diacetone acrylamide. The molar ratio of isoprene sulfonic acid sodium salt, acrylic acid and diacetone acrylamide in the aqueous monomer solution is 30 / 65 / 5. Add 224 parts of water and 4 parts of 35% hydrogen peroxide water to a four-necked separable flask with a capacity of 1 liter, which is equipped with a stirrer, a reflux cooler, a dropping funnel, and a nitrogen gas inlet tube, and keep the inner temperature of the flask at 100°C , added dropwise the above aqueous monomer solution over 2 hours. After the addition of the monomer aqueous solution was completed, the polymerization was continued for another hour, and then 29 parts of a 48% sodium hydroxide aqueous solution was added to partially neutralize it. The obtained partially neutralized produ...

Synthetic example 2

[0108]A monomer aqueous solution was prepared by mixing 326 parts of a 40% aqueous solution of isoprenesulfonate sodium salt and 221 parts of an 80% aqueous solution of acrylic acid. The molar ratio of isoprene sulfonic acid sodium salt and acrylic acid in the aqueous monomer solution is 25 / 75. Add 165 parts of water and 26 parts of 35% hydrogen peroxide water in a four-necked separable flask with a capacity of 1 liter, which is equipped with a stirrer, a reflux cooler, a dropping funnel, and a nitrogen inlet pipe, and the inner temperature of the flask is maintained at 100 °C, the above monomer aqueous solution was added dropwise over 2 hours. After the addition of the aqueous monomer solution was completed, the polymerization was continued for another hour, and then 45 parts of a 48% sodium hydroxide aqueous solution was added to partially neutralize it. The weight-average molecular weight of the partially neutralized product of the obtained isoprenesulfonic acid sodium sal...

Synthetic example 3

[0111] Put 681 parts of ion-exchanged water, 90 parts of 2-acrylamido-2-methylpropanesulfonic acid, 10 parts of N,N'-methylenebisacrylamide, and 20 parts of sodium persulfate 5% aqueous solution into the beaker and dissolve Make a water-soluble monomer solution.

[0112] In another beaker, an emulsifier solution in which 1,300 parts of cyclohexane and 70% sodium di(2-ethylhexyl)sulfosuccinate (Rikasafu M-30) were dissolved was prepared.

[0113] Slowly add the emulsifier solution dropwise to the water-soluble monomer solution prepared above while stirring, and add the total amount. Thereafter, it was cooled in an ice bath and irradiated with ultrasonic waves for 120 seconds three times using an ultrasonic disperser ("UH-600S", manufactured by SMT Co., Ltd.) to obtain an inverse emulsion. All the obtained emulsion was transferred to a separable flask, and heated at 70° C. for 3 hours. Thereafter, 2-acrylamido-2-methylpropanesulfonic acid-methylenebisacrylamide copolymer parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com