A kind of heat-resistant and heat-conducting anti-tear cable

A tear-resistant, high-temperature-resistant technology, applied in the direction of insulated cables, bendable cables, cables, etc., to achieve the effects of accelerating heat exchange, strengthening toughness and tear resistance, and increasing heat resistance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

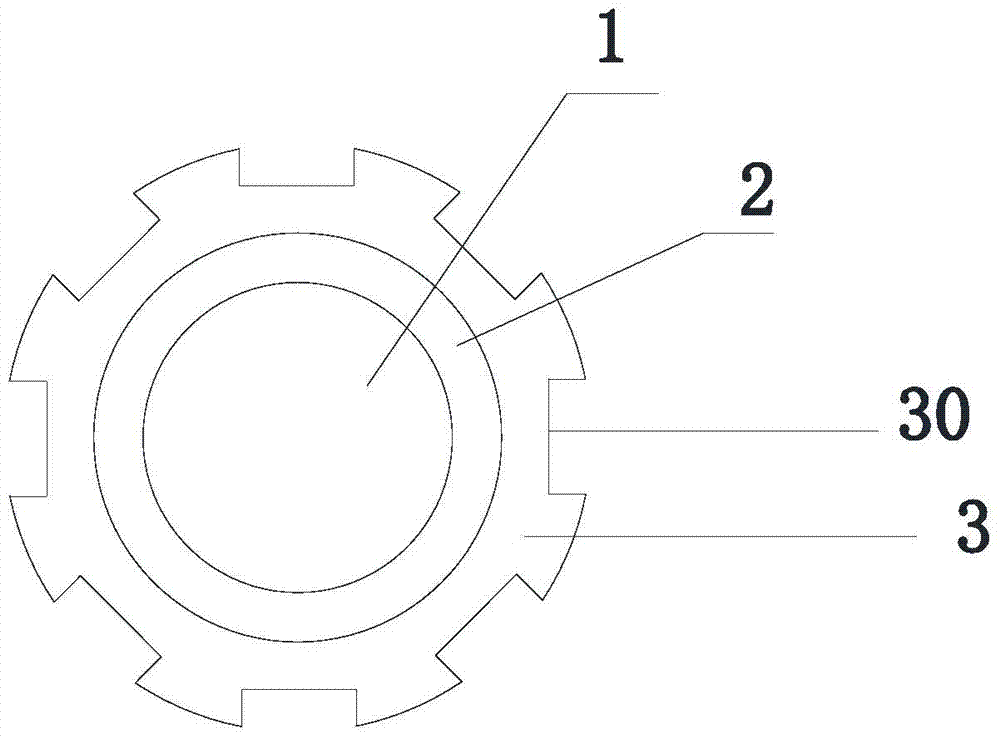

[0023] A heat-resistant and heat-conducting tear-proof cable, which includes a conductive cable core 1, an inner protective sheath 2 and an outer protective sheath 3, the inner protective sheath 2 covers the conductive cable core 1, the outer protective sheath 3 covers the inner protective sheath 2, and the outer protective sheath 2 covers the inner protective sheath 2. The periphery of the protective cover 3 is provided with a wrinkled texture 30 that is spirally wound around the periphery of the outer protective cover 3, which is conducive to high temperature heat dissipation;

[0024]Among them, the raw materials of the outer protective cover include by weight: 100 parts of modified phenolic resin, 30 parts of carbon black, 20 parts of talcum powder, 40 parts of silane-coupled magnesium hydroxide, 9 parts of microencapsulated red phosphorus, fumed silica 6 parts, 20 parts of epoxy fatty acid methyl ester, 30 parts of epoxy soybean oil, 1 part of dicumyl peroxide, 0.6 parts o...

Embodiment 2

[0027] A heat-resistant and heat-conducting tear-proof cable, which includes a conductive cable core 1, an inner protective sheath 2 and an outer protective sheath 3, the inner protective sheath 2 covers the conductive cable core 1, the outer protective sheath 3 covers the inner protective sheath 2, and the outer protective sheath 2 covers the inner protective sheath 2. The periphery of the protective cover 3 is provided with a wrinkled texture 30 that is spirally wound around the periphery of the outer protective cover 3, which is conducive to high temperature heat dissipation;

[0028] Among them, the raw materials of the outer protective cover include by weight: 120 parts of modified phenolic resin, 20 parts of carbon black, 30 parts of talcum powder, 20 parts of silane-coupled magnesium hydroxide, 11 parts of microencapsulated red phosphorus, fumed silica 4 parts, 30 parts of epoxy fatty acid methyl ester, 20 parts of epoxy soybean oil, 1.6 parts of dicumyl peroxide, 0.4 pa...

Embodiment 3

[0031] A heat-resistant and heat-conducting tear-proof cable, which includes a conductive cable core 1, an inner protective sheath 2 and an outer protective sheath 3, the inner protective sheath 2 covers the conductive cable core 1, the outer protective sheath 3 covers the inner protective sheath 2, and the outer protective sheath 2 covers the inner protective sheath 2. The periphery of the protective cover 3 is provided with a wrinkled texture 30 that is spirally wound around the periphery of the outer protective cover 3, which is conducive to high temperature heat dissipation;

[0032] Among them, the raw materials of the outer protective cover include by weight: 105 parts of modified phenolic resin, 27 parts of carbon black, 23 parts of talcum powder, 35 parts of silane-coupled magnesium hydroxide, 9.5 parts of microencapsulated red phosphorus, fumed silica 5.5 parts, 22 parts of epoxy fatty acid methyl ester, 28 parts of epoxy soybean oil, 1.2 parts of dicumyl peroxide, 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com