Nano boron phosphate catalytic carbonization flame-retardant epoxy resin and preparation method thereof

A technology of epoxy resin and boron phosphate, which is applied in the field of flame retardant materials to achieve the effects of low price, less addition and adjustable chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of nanometer boron phosphate is catalyzed into charcoal flame-retardant epoxy resin, taking described epoxy resin total mass (300g) as 100%, each component and its mass percentage are as follows:

[0038] E4484.5%,

[0039] m-PDA10.5%,

[0040] nano-BP 1.27 (the atomic molar ratio of boron and phosphorus is 1.27) 5.0%,

[0041] A preparation method of nano-boron phosphate catalyzed into charcoal and flame-retardant epoxy resin as described in this embodiment, the specific steps of the method are as follows:

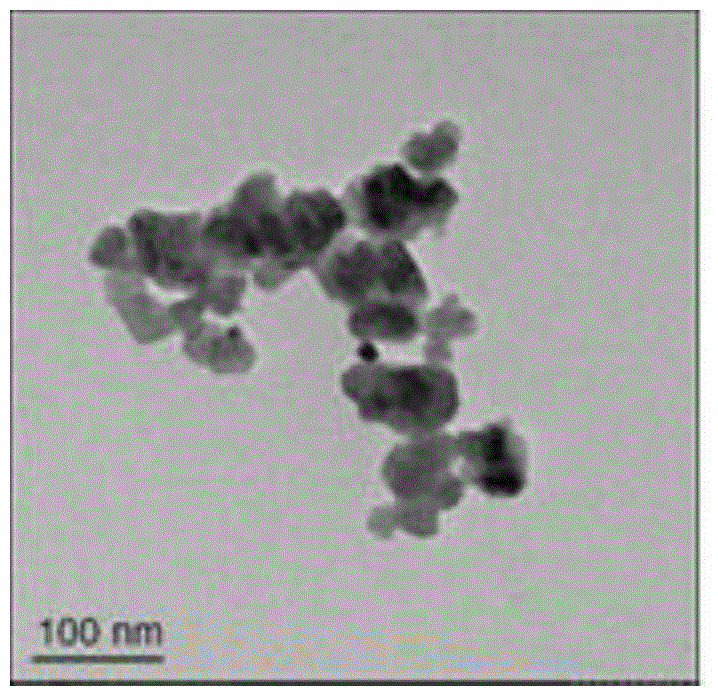

[0042] (1) Add boric acid (1.25mol) and phosphoric acid (1mol) into a beaker, stir at 110°C for 25min, and keep warm for 4h to obtain white solid 1; put white solid 1 in a tube furnace, and adjust the heating rate to 5°C / min, heated up to 500°C, calcined for 8h, cooled with the furnace, washed 3 times, and dried in vacuum to obtain solid acid nano boron phosphate white powder with a particle size of about 40-60nm (such as figure 1 Shown), the actual ato...

Embodiment 2

[0048] A kind of nanometer boron phosphate is catalyzed into charcoal flame-retardant epoxy resin, taking described epoxy resin total mass (300g) as 100%, each component and its mass percentage are as follows:

[0049] E4484.5%,

[0050] m-PDA10.5%,

[0051] nano-BP 1.06 (the atomic molar ratio of boron and phosphorus is 1.06) 5.0%,

[0052] A preparation method of nano-boron phosphate catalyzed into charcoal and flame-retardant epoxy resin as described in this embodiment, the specific steps of the method are as follows:

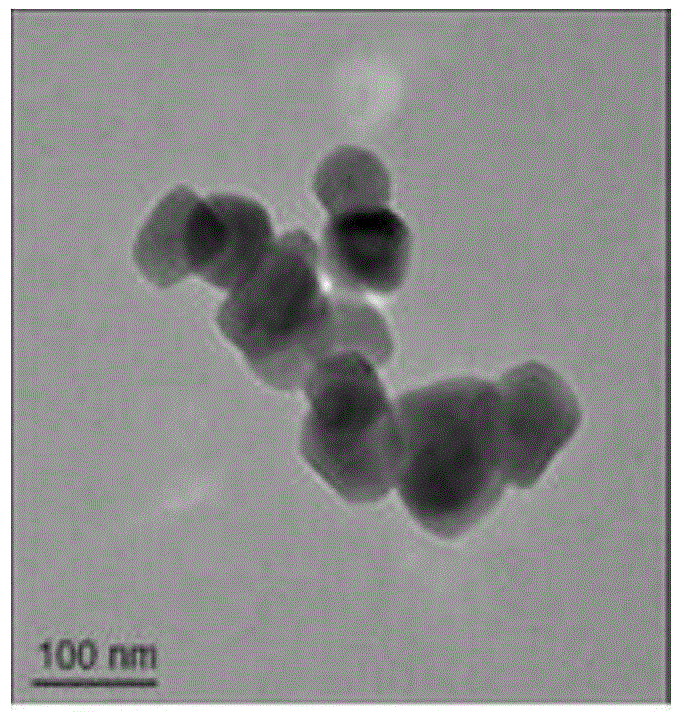

[0053] (1) Add boric acid (1mol) and phosphoric acid (1mol) into a beaker, stir at 120°C for 35min, and keep warm for 5h to obtain a white solid 1; put the white solid 1 in a tube furnace, and adjust the heating rate to 8°C / min, heated up to 700°C, calcined for 12 hours, cooled with the furnace, washed 5 times, and dried in vacuum to obtain solid acid nano boron phosphate white powder with a particle size of about 60-80nm (such as figure 2 Shown), the ...

Embodiment 3

[0059] A kind of nanometer boron phosphate is catalyzed into charcoal flame-retardant epoxy resin, taking described epoxy resin total mass (300g) as 100%, each component and its mass percentage are as follows:

[0060] E4484.5%,

[0061] m-PDA10.5%,

[0062] nano-BP 0.84 (the atomic molar ratio of boron and phosphorus is 0.84) 5.0%,

[0063] A preparation method of nano-boron phosphate catalyzed into charcoal and flame-retardant epoxy resin as described in this embodiment, the specific steps of the method are as follows:

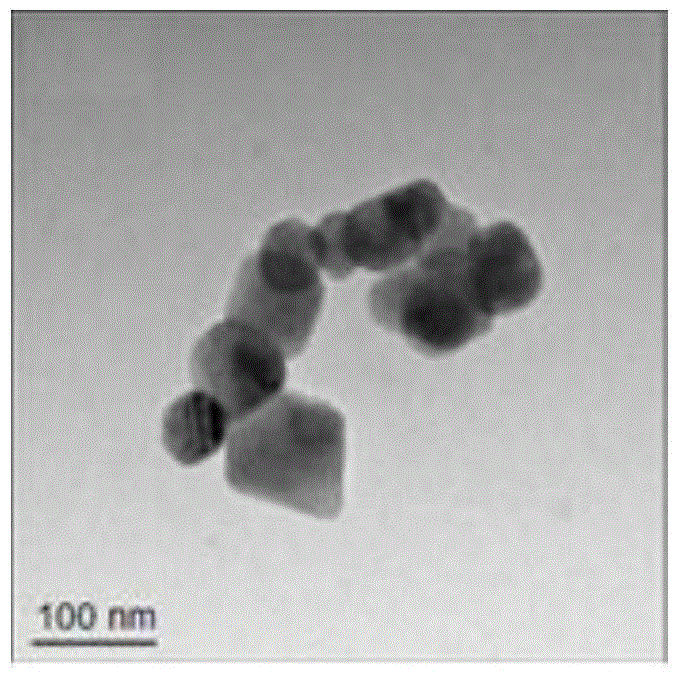

[0064] (1) Add boric acid (0.8mol) and phosphoric acid (1mol) into a beaker, stir at 115°C for 30min, and keep warm for 4.5h to obtain a white solid 1; put the white solid 1 in a tube furnace, and adjust the heating rate to 7 °C / min, heat up to 600 °C, calcined for 10 h, cooled with the furnace, washed 4 times, and dried in vacuum to obtain solid acid nano boron phosphate white powder with a particle size of about 40-80 nm (such as image 3 Shown), the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com