Heavy metal passivator and method for preparing and remediating cadmium and lead polluted soil

A technology of heavy metal passivation agent and lead pollution, applied in the restoration of polluted soil, chemical instruments and methods, soil conditioning materials, etc., can solve the problems of high production cost, complicated process, unsuitable for large-scale production, etc., and achieve passivation High chemical efficiency, simple production process, and reduced absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first method utilizes hydroxyaluminum mud to remediate Cd, Pb polluted soil in situ, carries out according to the following steps:

[0029] (1) After drying and grinding the alum mud, place it in a muffle furnace at 5°C min -1 Raise the temperature to 800°C at a constant speed, cool naturally after roasting for 1 hour, wash with water until neutral and dry. The resulting alum mud powder was mixed with 0.5 mol L -1 The NaOH solution was formulated according to the ratio of solid-liquid 0.5g:10mL, and 0.5% Tween-80 was added, heated in a water bath, and the reaction temperature and stirring speed were controlled to be 100°C and 600r min respectively. -1 The reaction time is 2 hours. After the end, it is cooled, precipitated, and washed to neutrality. The solid part is dried and ground to obtain hydroxyaluminum sludge, which is set aside;

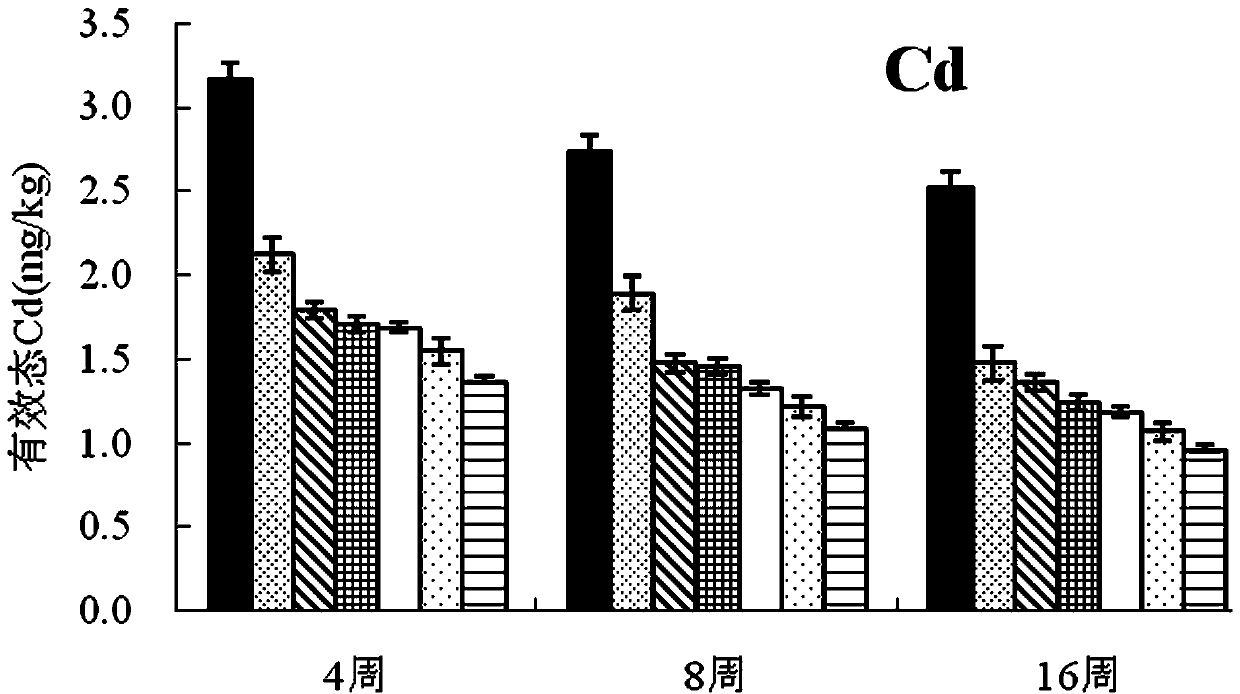

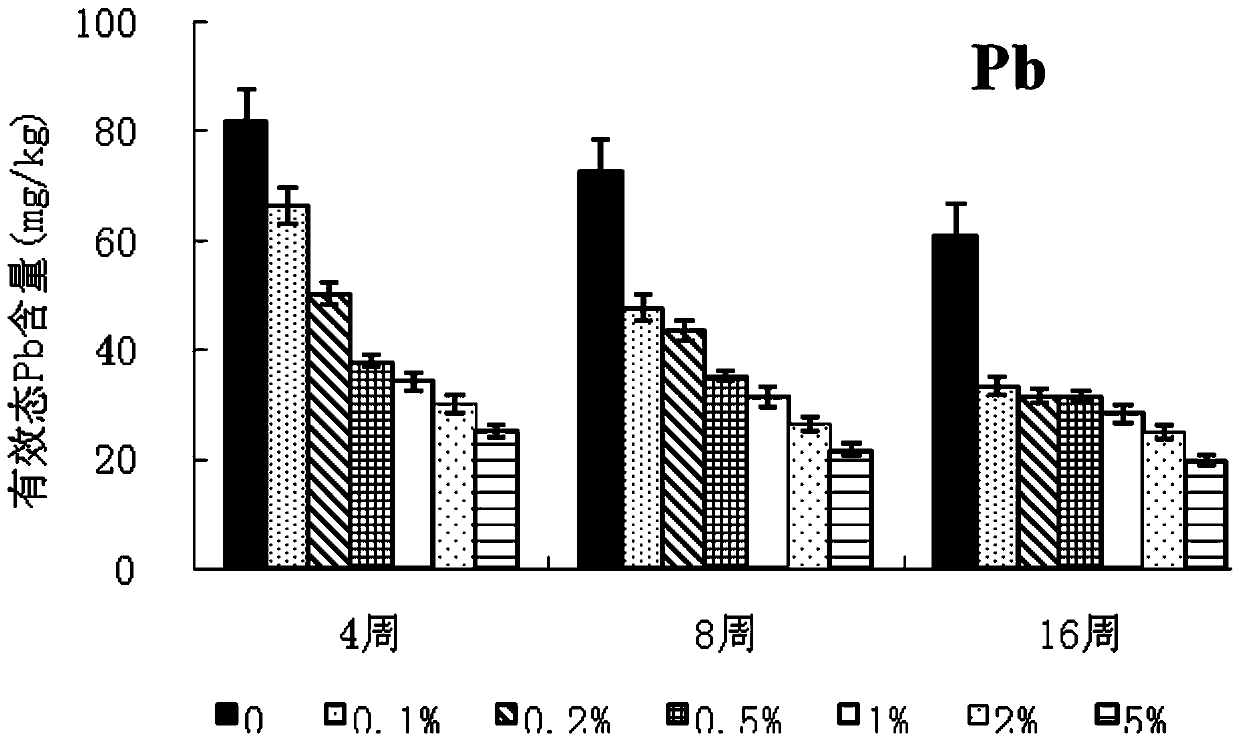

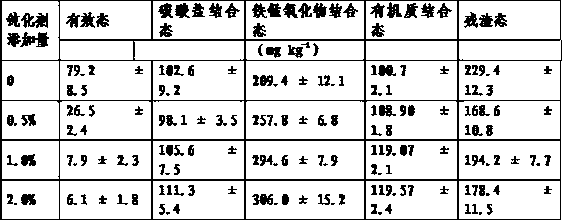

[0030] (2) The choice of in-situ remediation of Cd and Pb contaminated soil with hydroxyaluminum mud: the total Cd content is 1....

Embodiment 2

[0035] The second method utilizes hydroxyaluminum mud to remediate Cd, Pb polluted soil in situ, according to the following steps:

[0036] In this example,

[0037] Step (1) After drying and grinding the alum mud, place it in a muffle furnace at 5°C min -1 Raise the temperature to 800°C at a constant speed, cool naturally after roasting for 1 hour, wash with water until neutral and dry. The obtained alum mud powder and 2.0mol L -1 2.0g:10.0mL ratio of solid to liquid to prepare a solution, add 0.5% Tween-80, heat in a water bath, control the reaction temperature and stirring speed to 100°C and 600 r min, respectively -1 The reaction time is 3 hours. After the end, it is cooled, precipitated, and washed to neutrality. The solid part is dried and ground to obtain hydroxyaluminum mud, which is set aside;

[0038] Step (2) select the total Cd content 3.0 mg kg -1 and full Pb content 600 mg kg -1 The polluted soil was used as the soil to be repaired; step (3) applied the hydr...

Embodiment 3

[0040] The third method utilizes hydroxyaluminum mud to remediate Cd, Pb polluted soil in situ, according to the following steps:

[0041] In this example, the alum sludge was dried and ground and placed in a muffle furnace at 5°C min -1 Raise the temperature to 800°C at a constant speed, cool naturally after roasting for 2 hours, wash with water until neutral and dry. The obtained alum mud powder and 3.5mol L -1 The NaOH solution was prepared according to the ratio of solid-liquid 3.5g:10.0mL, and 0.5% Tween-80 was added, heated in a water bath, and the reaction temperature and stirring speed were controlled at 100°C and 600 r min, respectively. -1 The reaction time is 4 hours. After the end, it is cooled, precipitated, and washed to neutrality. The solid part is dried and ground to obtain hydroxyaluminum sludge for later use; in step (2), the total Cd content is selected to be 3.0 mg kg -1 and full Pb content 700 mg kg -1 The polluted soil was used as the soil to be repai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com