Low-sulfur and environment-friendly coal and processing method thereof

An environment-friendly, briquette technology, which is applied in the field of briquette processing, can solve the problems of transportation difficulties, and the resource utilization is not easy to find, and achieves the effect of reducing pollution, reducing emission and saving energy, and realizing the effect of resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

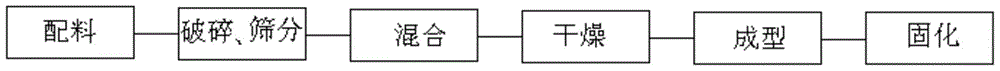

[0023] see figure 1 , The invention provides a low-sulfur environment-friendly briquette. For example, the low-sulfur environment-friendly briquette raw material is mainly composed of semi-coke powder, coal slime, and coal powder. The weight ratio of the raw material components is: semi-coke 40-70 parts, coal slime 20-50 parts, coal powder 20-50 parts , 1-5 parts of binder, 2-6 parts of additives; wherein, the semi-coke is obtained by dry distillation and pyrolysis of non-viscous or weakly viscous bituminous coal under medium and low temperature conditions, and the fixed carbon content ≥ 82% is a new carbon material, and the coal slime is a viscous waste with a fixed carbon content of 30%-52% produced during the coal washing process.

[0024] It can be understood that the briquette of the present invention is a processed clean energy product, and is one of all clean energy. Adding certain additives to pulverized or fine-grained coal materials to process them into briquettes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com