Brake chopper composite busbar

A composite busbar and brake chopping technology, which is applied in the direction of coupling devices, contact parts, fixed/insulated contact components, etc., can solve the problems of large space occupation, large circuit stray inductance, voltage spikes, etc., and achieve convenient maintenance and Maintain and solve the effect of large stray inductance and reduce system volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

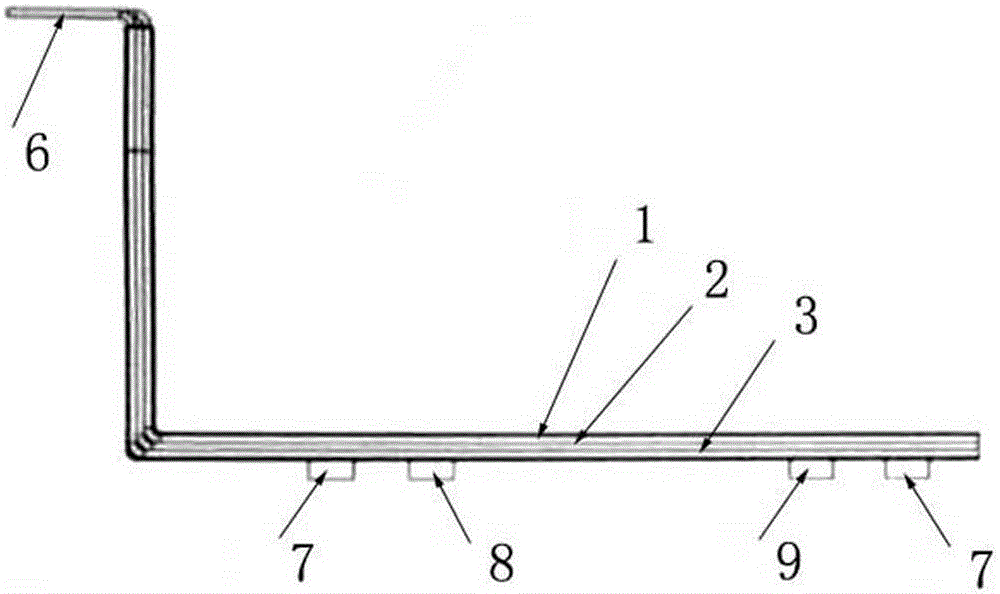

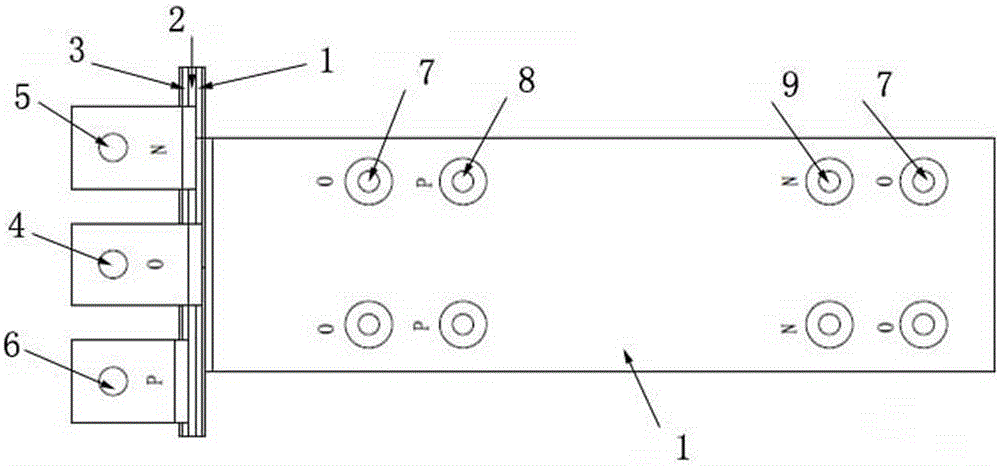

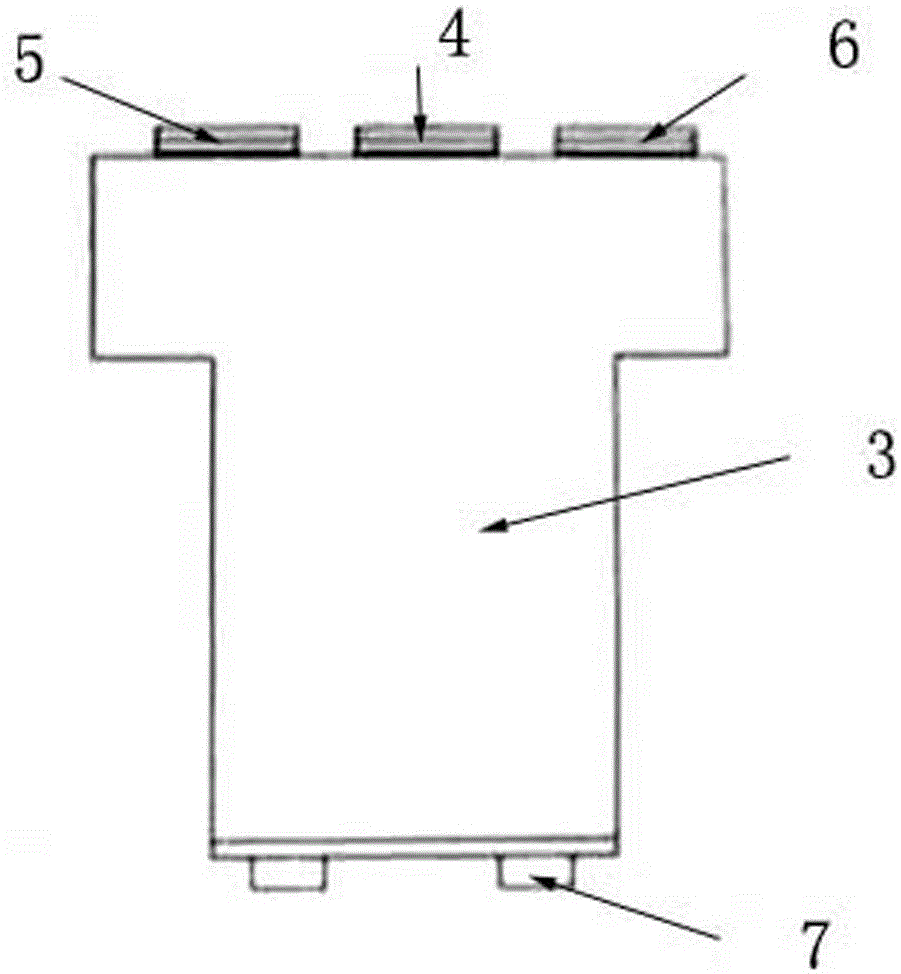

[0021] Such as figure 1 , 2 . As shown in 3, a brake chopper composite busbar, including three L-shaped flat busbars stacked together, the three busbars are O busbar 1 and N busbar from top to bottom For busbar 2 and P busbar 3, high insulation strength materials are provided between adjacent busbars; the tops of the short boards of O busbar 1, N busbar 2 and P busbar 3 are respectively extended outwards and provided with vertical O connection part 4, N connection part 5 and P connection part 6, O connection part 4, N connection part 5 and P connection part 6 are arranged in a staggered manner, wherein O connection part 4 is in the middle position, N connection part 5 and P connection part 6 Separately placed on both sides; the three busbars are taken as a whole, and a pair of O terminals 7, a pair of P terminals 8, A pair of N terminals 9 and a pair of O terminals 7, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com