Preparation method of multi-wall carbon nano tube/chitosan/oxidized regenerated cellulose composite hemostatic material

A technology of multi-walled carbon nanotubes and regenerated cellulose, which is applied in the field of biomedical composite materials, can solve the problems of slow hemostatic rate and small improvement in hemostatic performance, achieve reduced hemostasis time, overcome small improvement, and realize factory production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0035]Embodiment 1: This embodiment provides a method for preparing a carbon nanotube / chitosan / oxidized regenerated cellulose composite hemostatic material, and its specific steps are as follows:

[0036] (1) Dissolve 2g of low-molecular-weight chitosan (CTS) with 50ml of acetic acid to form a chitosan / acetic acid solution, add mass fractions of 0.1%, 0.5% and 1% CNTs to the chitosan / acetic acid solution, and ultrasonically disperse After 60 min, a uniformly dispersed CNTs solution was obtained.

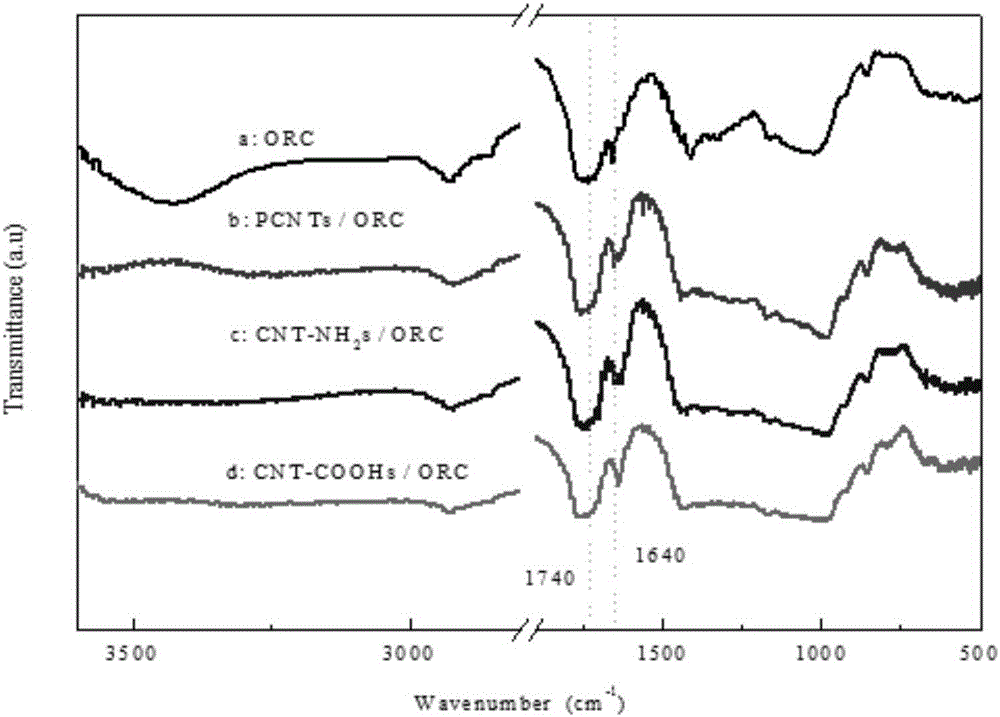

[0037] (2) Weigh 0.2g of oxidized regenerated cellulose, put it into the above CNTs solution and soak for 6h, 12h, 24h. Pre-freeze at ℃~-20℃ for 24 hours, put it into a freeze dryer after pre-freezing, and treat it for 24 hours at a temperature of -56℃~-20℃ and a vacuum of 10~40Pa to obtain carbon nanotubes / chitosan / oxidized Regenerated cellulose (CNTs / ORC) composite hemostatic material, its digital photos are shown in figure 1 As shown, the infrared spectrum is shown in figure 2...

specific Embodiment approach 2

[0038] Specific embodiment two: This embodiment provides a method for preparing an aminated carbon nanotube / chitosan / oxidized regenerated cellulose composite hemostatic material, and its specific steps are as follows:

[0039] (1) chitosan (CTS) with 50ml acetic acid dissolving 2g low molecular weight is made into chitosan / acetic acid solution, mass fraction 10%, 20%, 30%, 40%, 50% aminated carbon nanotube ( NH 2 -CNTs) were added into the chitosan / acetic acid solution, and ultrasonically dispersed for 60 min to obtain a uniformly dispersed CNTs solution.

[0040] (2) Weigh 0.2g of oxidized regenerated cellulose, put it into the above CNTs solution and soak for 6h, 12h, 24h. Pre-freeze at ℃~-20℃ for 24 hours, put it into a freeze dryer after pre-freezing, and treat it for 24 hours at a temperature of -56℃~-20℃ and a vacuum of 10~40Pa to obtain aminated carbon nanotubes / chitosan / oxidized regenerated cellulose (NH 2 -CNTs / ORC) composite hemostatic material, its digital photo...

specific Embodiment approach 3

[0041] Specific embodiment three: This embodiment provides a method for preparing a carboxylated carbon nanotube / chitosan / oxidized regenerated cellulose composite hemostatic material, and its specific steps are as follows:

[0042] (1) Chitosan (CTS) of 2g low molecular weight is made into chitosan / acetic acid solution with 50% acetic acid, massfraction 10%, 20%, 30%, 40%, 50% CNTs are added chitosan / In the acetic acid solution, ultrasonically disperse for 60 min to obtain a uniformly dispersed solution of carboxylated carbon nanotubes (COOH-CNTs), and then add 0.1 g of DCC to react for 12 h.

[0043] (2) Weigh 0.2g of oxidized regenerated cellulose, put it into the above CNTs solution and soak for 6h, 12h, 24h. Pre-freeze at ℃~-20℃ for 24 hours, put it into a freeze dryer after pre-freezing, and treat it for 24 hours at a temperature of -56℃~-20℃ and a vacuum of 10~40Pa to obtain carboxylated carbon nanotubes / chitosan / Oxidized regenerated cellulose (COOH-CNTs / ORC) composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com