Preparation method of oxidized regenerated cellulose hemostatic material with micro-nano composite structure

A technology of micro-nano composite structure and regenerated cellulose, which can be applied to artificial filaments made of cellulose derivatives, wet spinning, medical science, etc. The effect of fast hemostasis, short hemostasis time and easy decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

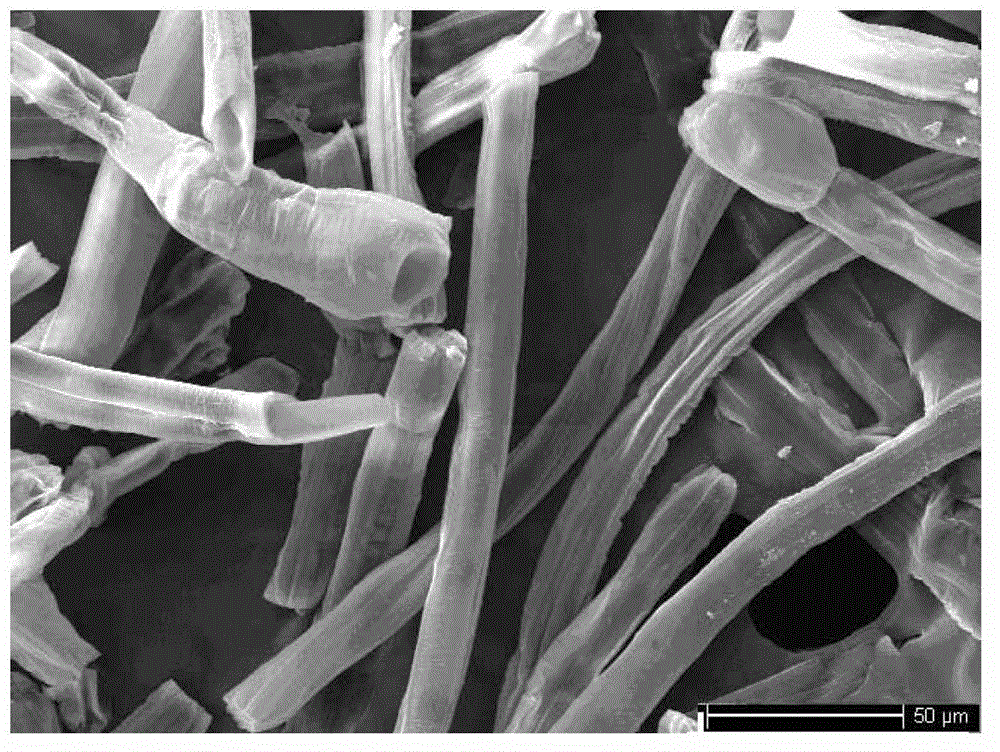

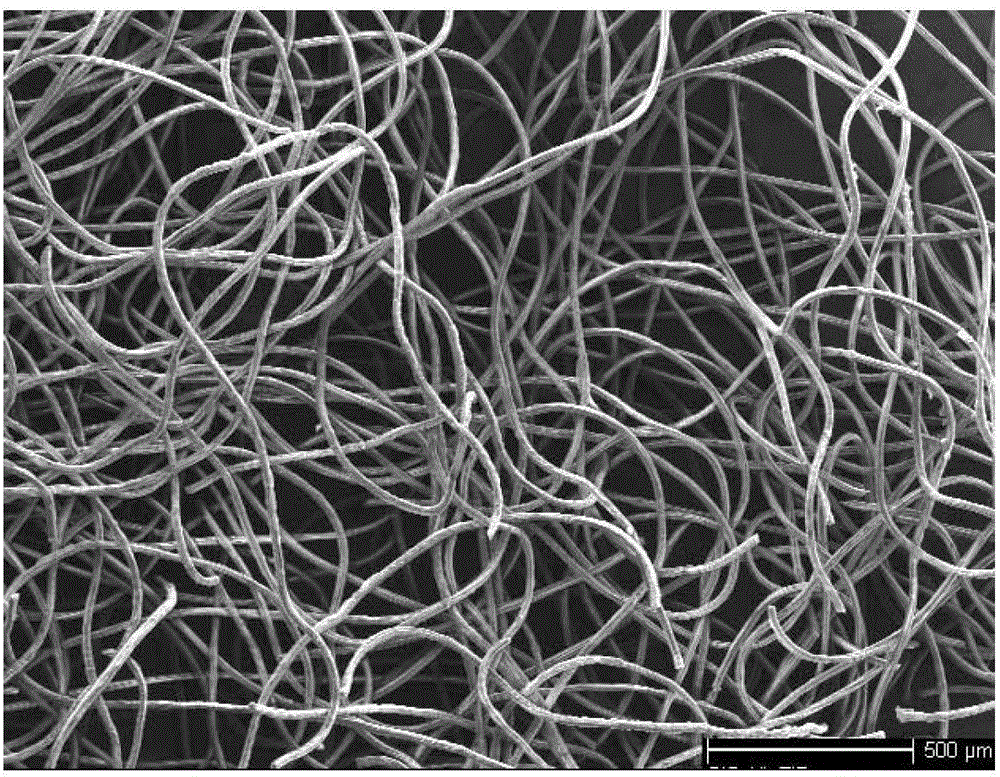

[0013] Specific Embodiment 1: A method for preparing an oxidized regenerated cellulose-based hemostatic material with a micro-nano composite structure according to this embodiment is implemented in the following steps:

[0014] 1. Raise the temperature of the ionic liquid to 95-115°C, then dissolve the cellulose in the ionic liquid and keep it warm, and stir once every 5-20 minutes. When the cellulose is completely dissolved, the cellulose solution is obtained, and the cellulose solution is cooled to 80-80 90°C, and keep it in a static state for later use; wherein, the mass fraction of cellulose in the ionic liquid is 2% to 6%;

[0015] 2. Put the cellulose solution prepared in step 1 into the syringe of the electrospinning machine for spinning, and the nanofibers obtained by spinning are coagulated in deionized water at 15-25°C for 10-30min, and then filtered to take the filtrate for further processing. Rinse, put the filtrate after rinsing into deionized water, stir evenly t...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ionic liquid in Step 1 is 1-allyl-3-methylimidazole. Other steps and parameters are the same as those in Embodiment 1.

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the cellulose needs to be dried in a vacuum oven at 60-80°C for 0.5-1.5 hours before use. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

specific Embodiment approach 4

[0021] Specific Embodiment 4: The difference between this embodiment and one of specific embodiments 1 to 3 is that the rinsing in Step 2 and the rinsing in Step 4 are performed with medical ethanol. Other steps and parameters are the same as those in Embodiments 1 to 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com