Laser selected area fusion forming method for weldless metal dot matrix component

A technology of laser selective melting and metal lattice, which is applied in the coating process and coating of metal materials, can solve the problems of single lattice structure, welding seam defects, low forming quality, etc. Short, excellent product performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

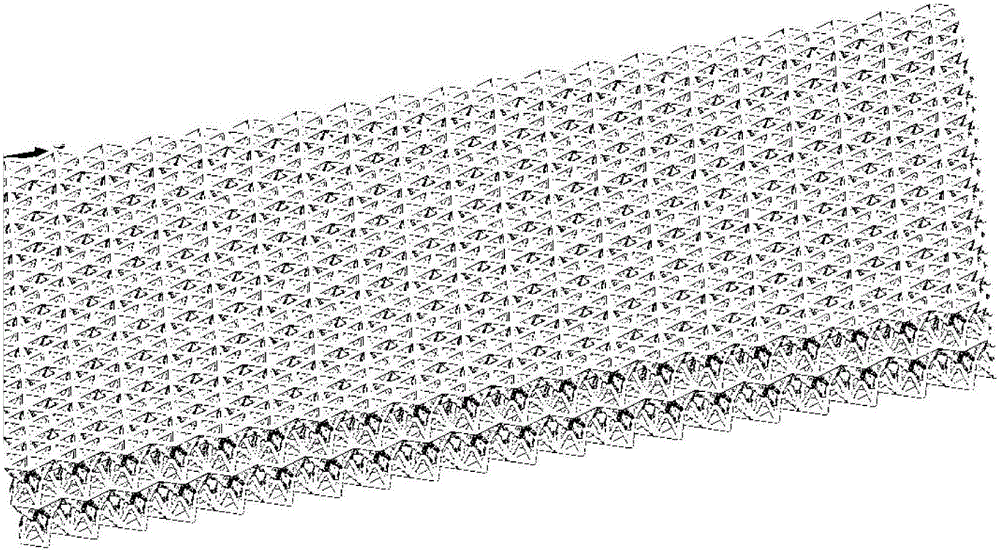

[0033] Such as image 3 As shown, the specific specifications of all formed weldless metal lattice members in this embodiment are: the material is TC4 titanium alloy, the size is 200mm×100mm×20mm, and there is no welded metal lattice member with tetrahedral lattice structure .

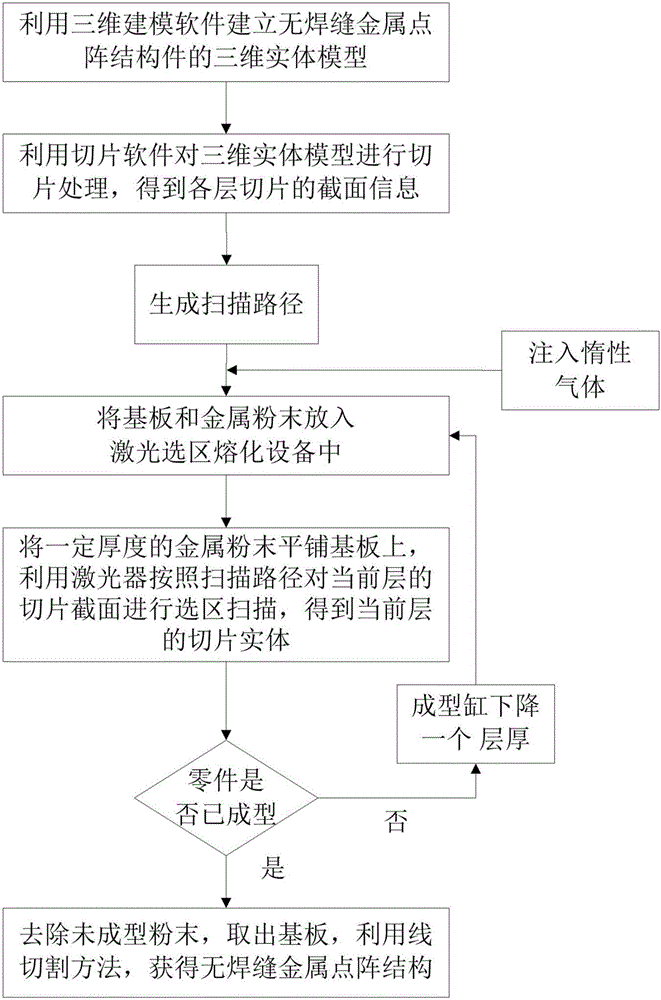

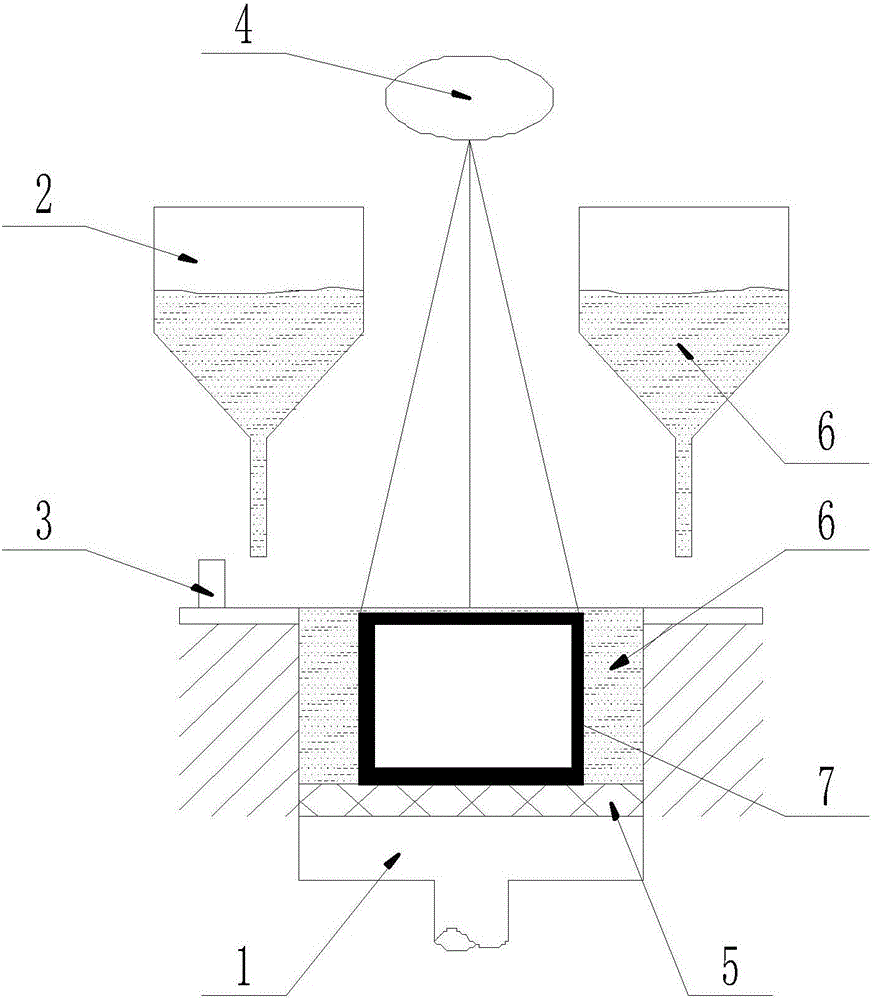

[0034] combine figure 1 with figure 2 , the laser selective melting forming method of the weldless metal lattice member in this embodiment includes the following steps:

[0035] Step 1, according to the structure and the size of the weldless metal lattice member to be formed, use three-dimensional modeling software to establish a three-dimensional solid model in a computer; the three-dimensional modeling software used in this embodiment is 3-matic software; this embodiment The established three-dimensional solid model of the weldless metal lattice member is shown in image 3 ;

[0036] Step 2, import the 3D solid model established in step 1 into the slicing software, use the slicing software to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com