Electron beam selective melting forming method for weld-less metal honeycomb components

A technology of metal honeycomb and selective melting, which is applied in the field of electron beam selective melting of weldless metal honeycomb components. Time and other issues, to achieve the effect of simple and reliable operation, strong repeatability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

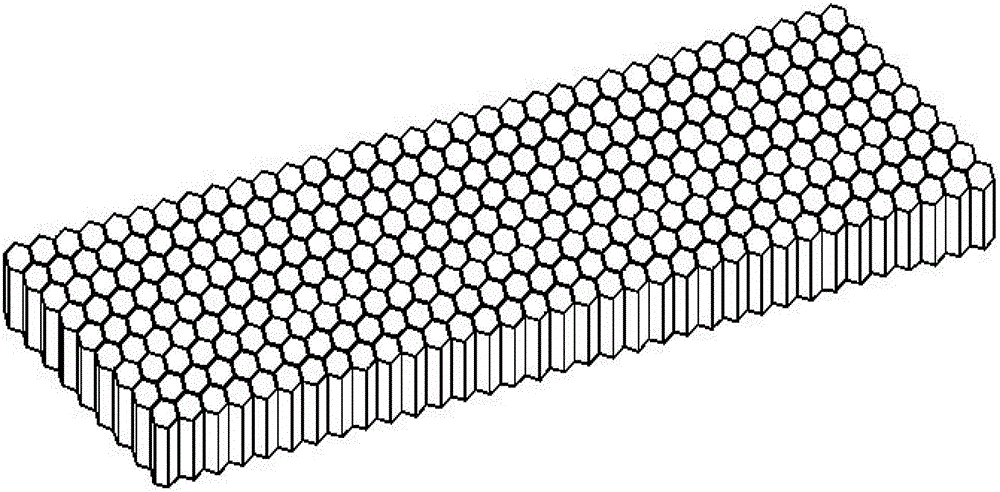

[0047] The specific specifications of the weldless metal honeycomb component to be formed in this embodiment are: the material is titanium alloy (specifically TiAl alloy), the size is 200mm (length) × 100mm (width) × 18mm (height), and it has a regular hexagon (The diameter of the inscribed circle of a regular hexagon is 1.6mm) A metal honeycomb plate without welds with a honeycomb through-hole structure.

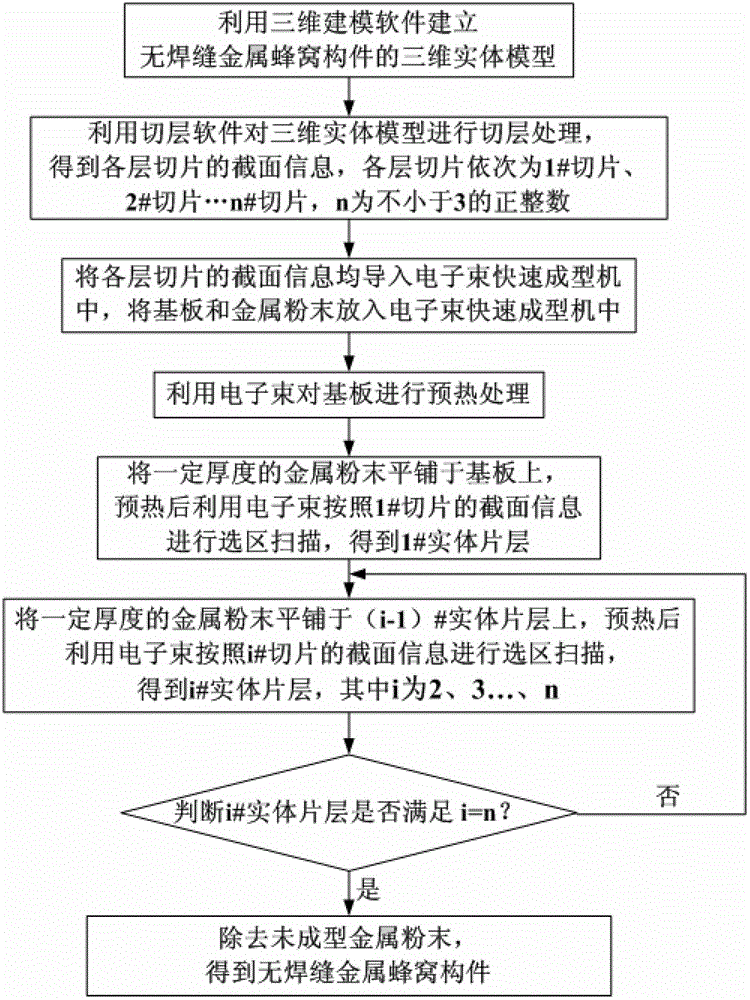

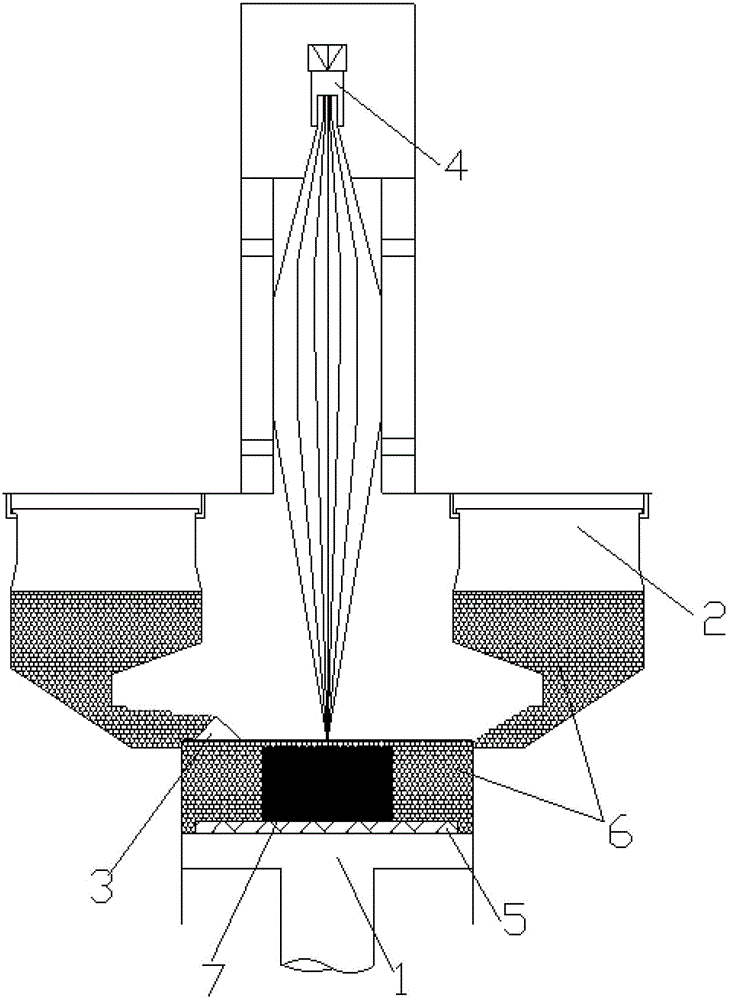

[0048] combine figure 1 and figure 2 , the electron beam selective melting molding method of the non-welded metal honeycomb member of the present embodiment comprises the following steps:

[0049] Step 1, according to the structure and size of the weldless metal honeycomb member to be formed, utilize the three-dimensional modeling software to set up the three-dimensional solid model of the weldless metal honeycomb member in the computer; the three-dimensional modeling software that the present embodiment adopts is Solidworks software ; The three-dimensional solid model o...

Embodiment 2

[0064] The specific specifications of the weldless metal honeycomb component to be formed in this embodiment are: the material is titanium alloy (specifically Ti6Al4V alloy), the outer diameter is 149mm, the inner diameter is 117mm, the height is 53.5mm, and it is arranged in an orderly manner along the radial direction A non-welded metal honeycomb rotating part with a regular hexagonal (diameter of the inscribed circle of the regular hexagon is 1.6mm) honeycomb through-hole structure.

[0065] combine figure 1 and figure 2 , the electron beam selective melting molding method of the non-welded metal honeycomb member of the present embodiment comprises the following steps:

[0066] Step 1, according to the structure and size of the weldless metal honeycomb member to be formed, use three-dimensional modeling software to establish a three-dimensional solid model of the weldless metal honeycomb member; the three-dimensional modeling software used in this embodiment is Solidworks...

Embodiment 3

[0081] The specific specifications of the weldless metal honeycomb component to be formed in this embodiment are: the material is nickel alloy (the specific grade is Inconel625), the outer diameter is 120mm, the inner diameter is 60mm, and the height is 35mm, and there are orderly arranged along the radial direction. Regular hexagonal (diameter of the inscribed circle of the regular hexagon is 3mm) non-welded metal honeycomb rotating parts with honeycomb through-hole structure.

[0082] to combine figure 1 and figure 2 , the electron beam selective melting molding method of the non-welded metal honeycomb member of the present embodiment comprises the following steps:

[0083] Step 1, according to the structure and size of the weldless metal honeycomb member to be formed, use three-dimensional modeling software to establish a three-dimensional solid model of the weldless metal honeycomb member; the three-dimensional modeling software used in this embodiment is Pro / Engineer so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com