A kind of graphite phase carbon nitride nanosheet material and its preparation method and application

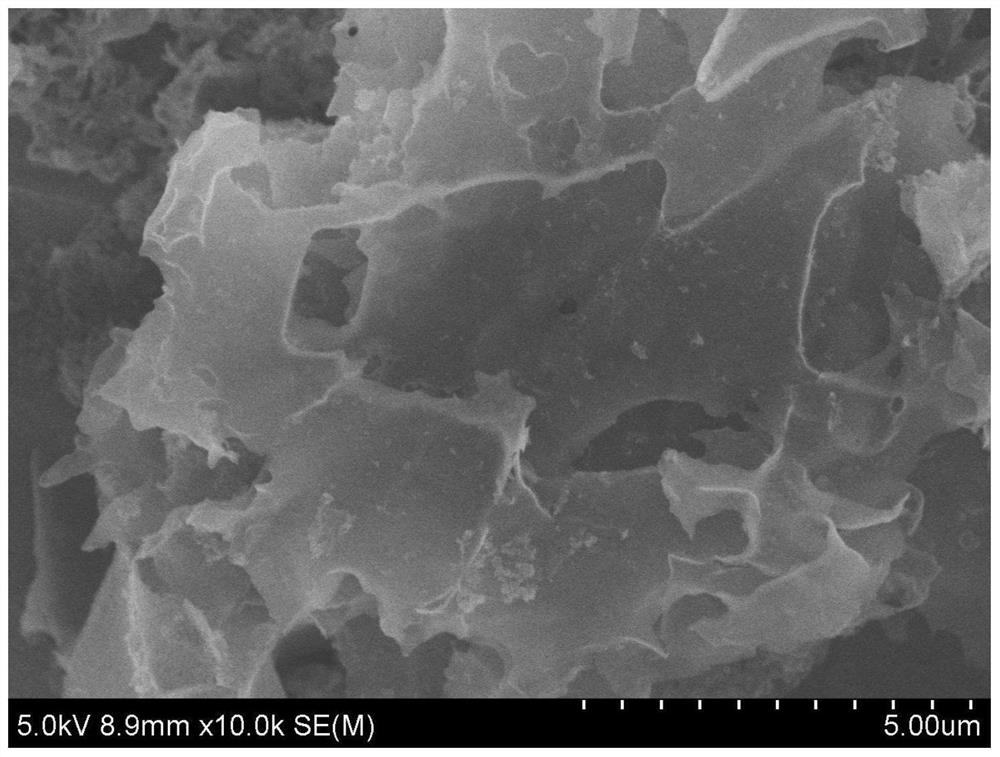

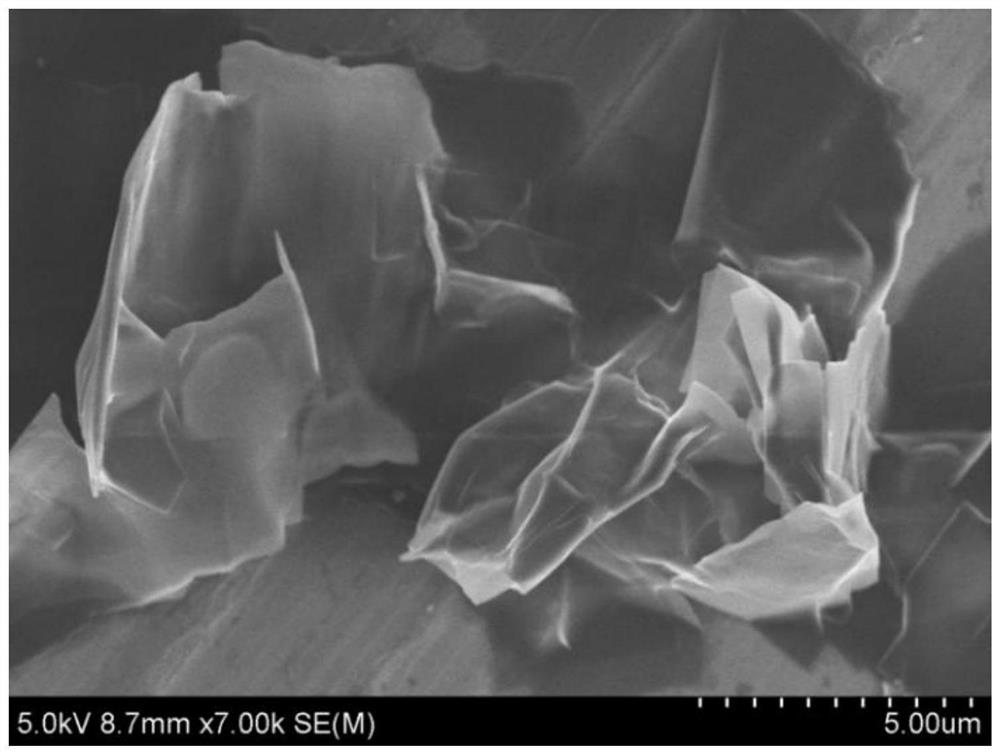

A technology of graphite phase carbon nitride and nanosheets, which is applied in the field of photocatalytic materials, can solve the problems of incomplete sheets and many holes in the sheets, and achieve the effects of easy operation, easy control of the reaction process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of a graphitic phase carbon nitride nanosheet material, comprising the following steps:

[0030] Mixing melamine and glacial acetic acid for acidification treatment to obtain an acidification treatment precursor;

[0031] The acidified precursor is calcined for the first time at 500-550°C for 3-5 hours, cooled to room temperature and then calcined for the second time at 500-600°C for 2-4 hours to obtain graphite phase carbon nitride nanosheet material.

[0032] The invention mixes melamine and glacial acetic acid and then performs acidification treatment to obtain an acidification treatment precursor. The present invention uses melamine as a raw material, and uses glacial acetic acid to acidify it, avoiding the problem in the prior art that the melamine structure is easily damaged by using inorganic strong acids, resulting in incomplete graphite phase carbon nitride nanosheets and even many holes; Glacial acetic acid is an o...

Embodiment 1

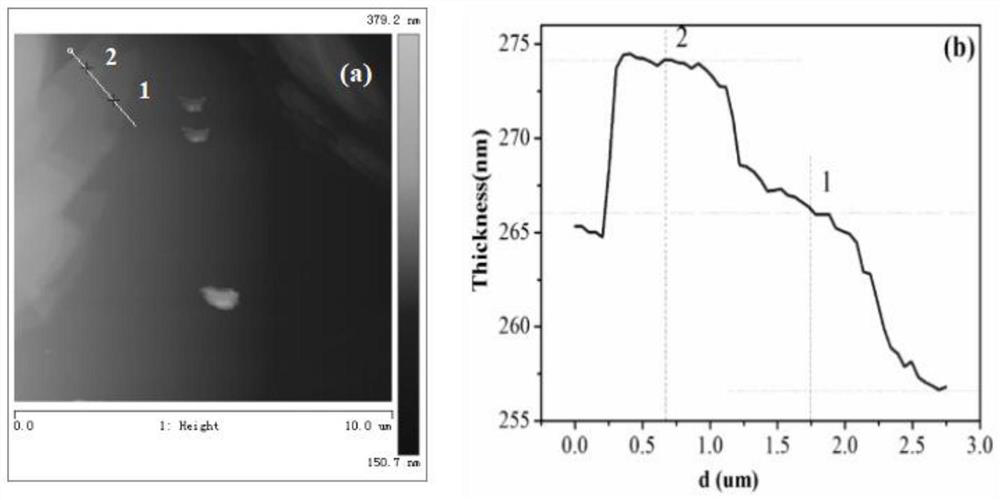

[0046] Weigh 30g of melamine, put it into 100mL of glacial acetic acid with a purity greater than 99.5wt%, stir for 12h with a magnetic stirrer at room temperature (25°C), stop stirring, filter the resulting system, and deionize the resulting solid material Wash until neutral, then put it in a drying oven to dry at a constant temperature of 50°C, transfer it to a crucible after drying, and raise the temperature from room temperature to 500°C at a rate of 10°C / min in an air atmosphere, keep it for calcination for 3 hours, and then Cool the furnace to room temperature; then raise the temperature from room temperature to 500 °C at a rate of 2 °C / min in an air atmosphere, keep the temperature for calcination for 2 hours, and cool to room temperature with the furnace. The obtained product is taken out and ground to obtain a multi-sheet structure The graphitic phase carbon nitride nanosheet material, wherein, the thickness of the monolithic graphite phase carbon nitride nanosheet is ...

Embodiment 2

[0048] Weigh 20 g of melamine, put it into 100 mL of glacial acetic acid with a purity greater than 99.5 wt %, stir for 24 hours at room temperature (25° C.) with a magnetic stirrer, and after the stirring is stopped, filter the resulting system, and deionize the resulting solid material Wash until neutral, then put it in a drying oven to dry at a constant temperature of 50°C, transfer it to a crucible after drying, and raise the temperature from room temperature to 520°C at a rate of 10°C / min in an air atmosphere, keep it for calcination for 4 hours, and then Cool the furnace to room temperature; then raise the temperature from room temperature to 550 °C at a rate of 2 °C / min in an air atmosphere, heat-preserve and calcinate for 3 hours, cool to room temperature with the furnace, take out the obtained product and grind it to obtain a multi-sheet structure The graphitic phase carbon nitride nanosheet material, wherein, the thickness of the monolithic graphite phase carbon nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com