Manufacturing process for four-degree-of-freedom piezoelectric micro-gripper

A manufacturing process and micro-clamp technology, which is applied in the field of four-degree-of-freedom piezoelectric micro-clamp manufacturing process, can solve the problems of increased complexity, design difficulty and cost of micro-assembly and micro-operating system, and reduce the design cost. Difficulty and complexity, reduced mass and volume, good repeatability of output displacement and output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

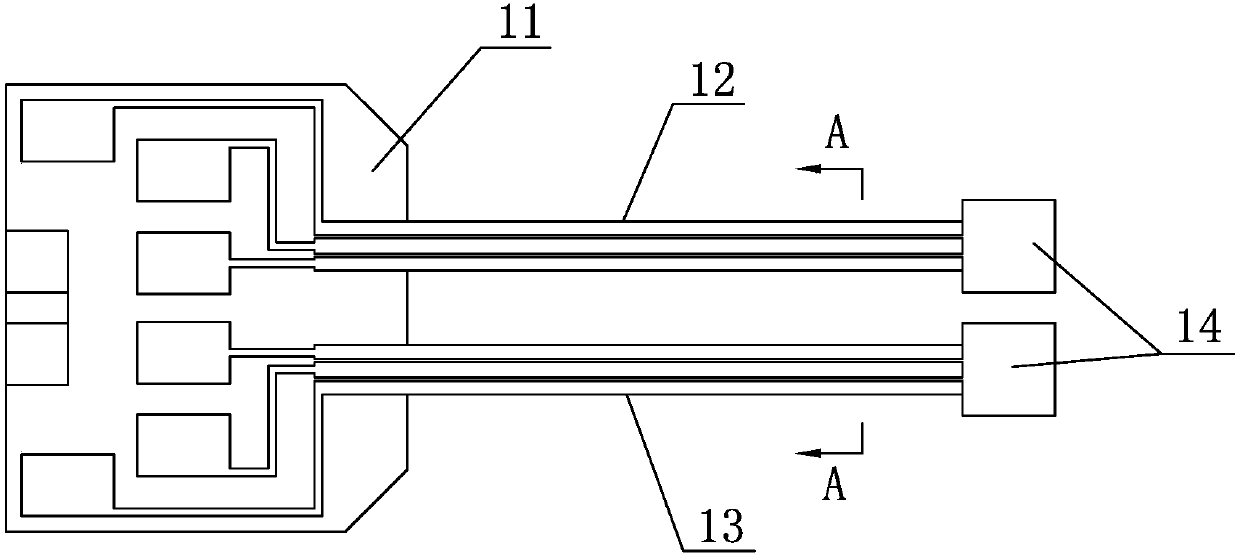

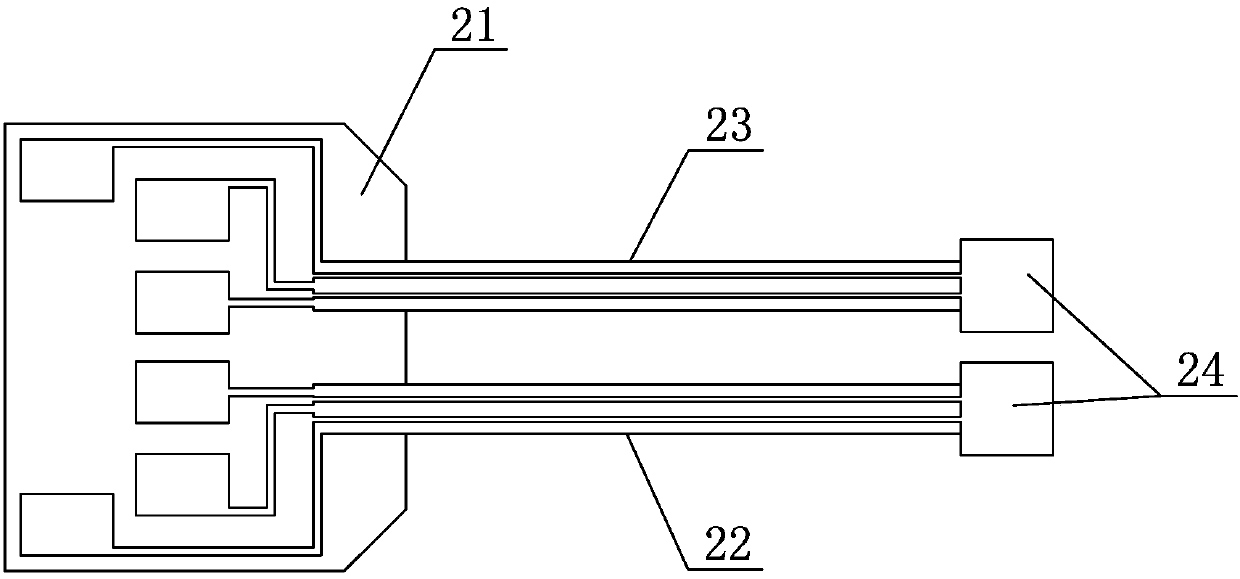

[0024] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

[0025] As shown in the figure, the manufacturing process of a four-degree-of-freedom piezoelectric micro clamp includes the following specific steps:

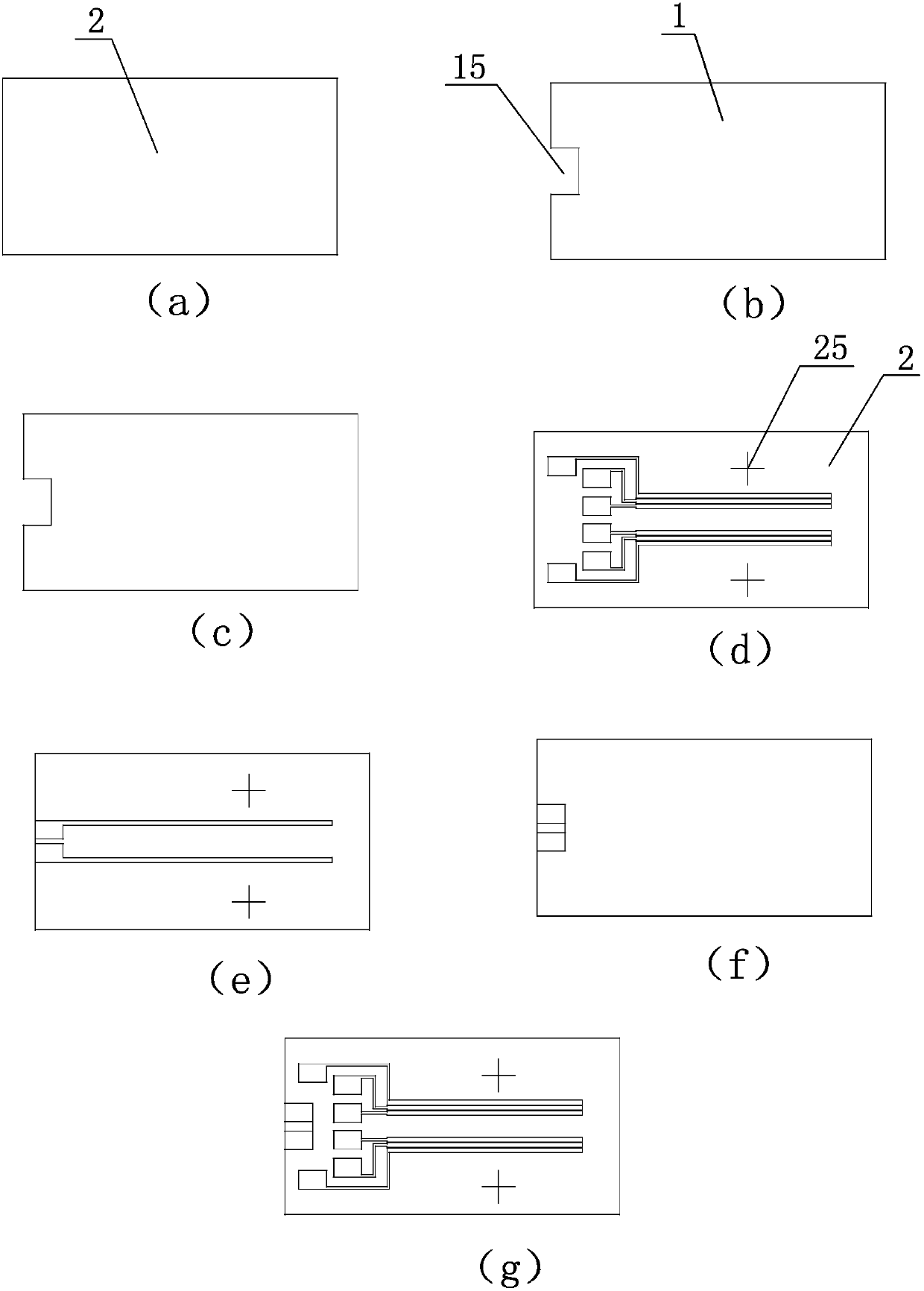

[0026] (1) Take two piezoelectric ceramic single wafers, one of which is used as upper wafer 1, and the other as lower wafer 2 (such as figure 1 (a)), and a square notch 15 is processed by ultraviolet laser cutting on one end of the upper wafer 1 (such as figure 1 (b) shown);

[0027] (2). The upper wafer 1 and the lower wafer 2 are polarized, and the electrodes on the bonding surface of the upper wafer 1 after the polarization are completely removed by photolithography (such as figure 1 (c) shown);

[0028] (3) The first left bottom electrode 22-1, the second left bottom electrode 22-2, and the third left bottom electrode 22-3, which are independent and arranged side by side, are lithographically etched on the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com