Manufacturing system of packing plate for wire and cable winding tool

A wire and cable, manufacturing system technology, applied in the field of cable materials, machinery and equipment, can solve the problems of not being able to effectively protect cables, not revealing effective substitutes for packaging materials, etc., to achieve excellent mildew resistance, excellent adhesion, Simple way to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

[0031] Implementation examples 1 and 2 are implementation examples of the packaging board and the manufacturing method of the present invention; implementation examples 3 and 4 are implementation examples of the system for manufacturing the packaging board of the present invention.

Embodiment 1

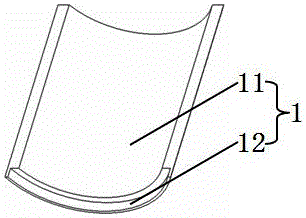

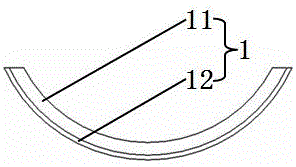

[0033] please see figure 1 and figure 2 , a packaging board 1 for wire and cable trays, which is composed of a curved board body 11 and a moisture-proof layer 12 adhered to the outer edge of the board body; the board body is made of the following raw materials in parts by weight: 70-90 parts of wood fiber, 15-20 parts of adhesive, 3-8 parts of coupling agent, 0.3-1 part of spicy body, 0.1-0.3 parts of garlic body; the wood fiber is made of sawdust or grass clippings or leaves Chips or two or more materials among wood chips, grass chips, and leaf chips, the moisture content of the wood fibers is ≤5%, and the fineness of the materials in the wood fibers is ≤100 mesh; the binder is ethylene- Vinyl acetate copolymer or polyamide or polyethylene or polyvinyl alcohol; the coupling agent is commercially available model A-150 or A-151 or A-171 or A-172 or A-1100 or A-187 or A-174 or A-1891 or A-189 or A-1120 or KH-550 or KH-560 or KH-570 or KH-580 or KH-590 or KH-902 or KH-903 or K...

Embodiment 2

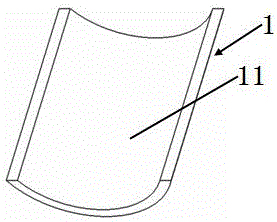

[0037] please see image 3 and Figure 4 , a packaging board 1 for wire and cable trays, which is composed of a curved board body 11; the board body is made of the following raw materials in parts by weight: 70-90 parts of wood fiber, 15-90 parts of adhesive 20 parts, 3-8 parts of coupling agent, 0.3-1 part of spicy body, 0.1-0.3 part of garlic body; the wood fiber is made of wood chips or grass chips or leaf chips or wood chips, grass chips, and leaf chips Composed of two or more materials, the moisture content of the wood fiber is ≤5%, and the fineness of the material in the wood fiber is ≤100 mesh; the binder is ethylene-vinyl acetate copolymer or polyamide or polyethylene or polyamide Vinyl alcohol; the coupling agent is a commercially available model of A-150 or A-151 or A-171 or A-172 or A-1100 or A-187 or A-174 or A-1891 or A-189 or Silane coupling agent of A-1120 or KH-550 or KH-560 or KH-570 or KH-580 or KH-590 or KH-902 or KH-903 or KH-792; the water content of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com