Preparation method for hydrophobic high-dispersion white carbon black

A high-dispersion silica, hydrophobic technology, applied in the direction of silica, silicon oxide, etc., can solve the problem of reducing the hydroxyl content of silica and hydrophilicity, poor compatibility between silica and rubber macromolecules, and macromolecules. Poor compatibility and other problems, to achieve the effects of enhanced wettability, improved wear resistance, and improved lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

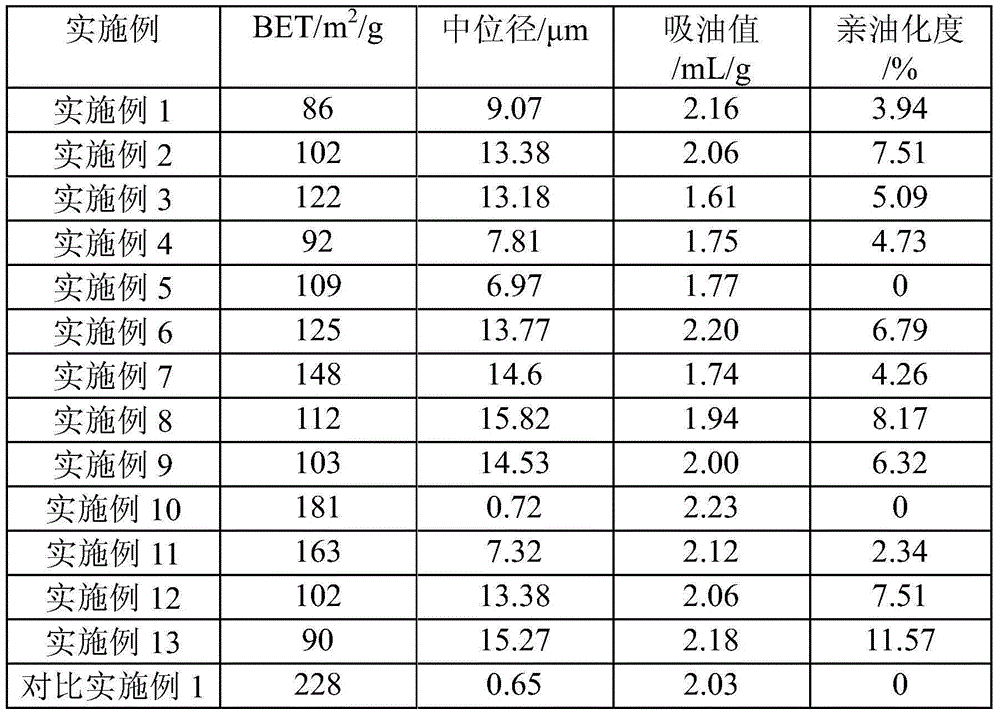

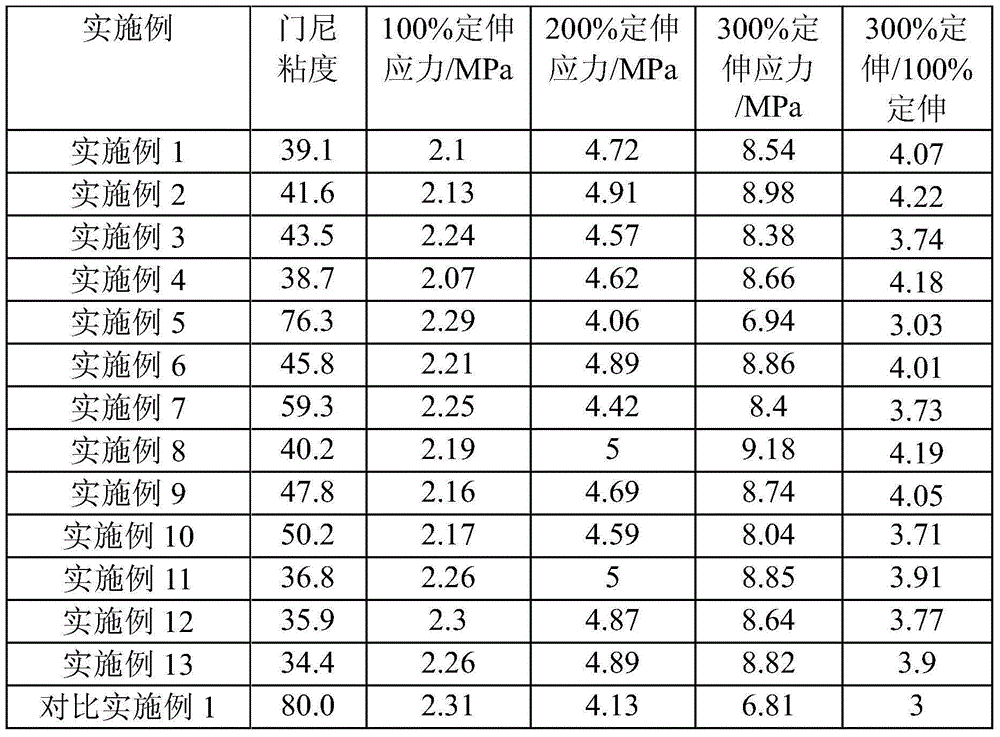

Examples

Embodiment 1

[0014] The concentration of sulfuric acid is 2.5mol / L, the modulus of water glass is 3.3, SiO 2 The molar concentration is 1.34mol / L. Pipette 912mL of water glass solution, add it into a 2L stirred reaction kettle, stir (rotate at 250rpm) and heat up to 90°C. Add above-mentioned sulfuric acid solution dropwise with 210min, make pH value be reduced to 3.5, after adding acid, continue to add silane coupling agent KH570 alcohol aqueous solution (silane coupling agent KH570 volume percent consumption is 1.5% of total volume of reaction solution, V 硅烷偶联剂KH570 =13.7mL) for modification reaction, the modification time is 90min, filtered, washed with deionized water and desalted. Wash until the conductivity of the water is less than or equal to 100 μs / cm, and dry in an oven at 105°C until the moisture content of the product is 6.2 wt%, to obtain a hydrophobic and highly dispersed precipitated white carbon black powder product.

Embodiment 2

[0016] Pipette 912mL of the same water glass solution as in Example 1, add it into a 2L stirred reactor, stir (rotate at 250rpm) and heat up to 85°C. Add 2.5mol / L sulfuric acid solution dropwise over 180min to reduce the pH value to 4.5. After adding the acid, continue to add the silane coupling agent KH570 alcohol aqueous solution (the volume percentage of the silane coupling agent KH570 is 1.5% of the total volume of the reaction solution, V 硅烷偶联剂KH570 =13.7mL) for modification reaction, the modification time is 90min, filtered, washed with deionized water and desalted. Wash until the conductivity of the water is less than or equal to 100 μs / cm, and dry in an oven at 105°C until the moisture content of the product is 5.8 wt%, to obtain a hydrophobic and highly dispersed precipitated white carbon black powder product.

Embodiment 3

[0018] Pipette 912mL of the same water glass solution as in Example 1, add it into a 2L stirred reactor, and stir (rotate at 250rpm) to raise the temperature to 80°C. Add 2.5mol / L sulfuric acid solution dropwise over 150min to reduce the pH value to 6. After adding the acid, continue to add the silane coupling agent KH570 alcohol aqueous solution (the volume percentage of the silane coupling agent KH570 is 1.5% of the total volume of the reaction solution, V 硅烷偶联剂KH570 =13.7mL) for modification reaction, the modification time is 90min, filtered, washed with deionized water and desalted. Wash until the conductivity of the water is less than or equal to 100 μs / cm, and dry in an oven at 105°C until the moisture content of the product is 5.8 wt%, to obtain a hydrophobic and highly dispersed precipitated white carbon black powder product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com