Preparation method of carbon dot coated cerium dioxide material and application of material in fluorine ion adsorption and detection

A technology of ceria and carbon dots, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problem of limited effective adsorption, low content of active groups, poor dispersion, etc. problems, to achieve good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

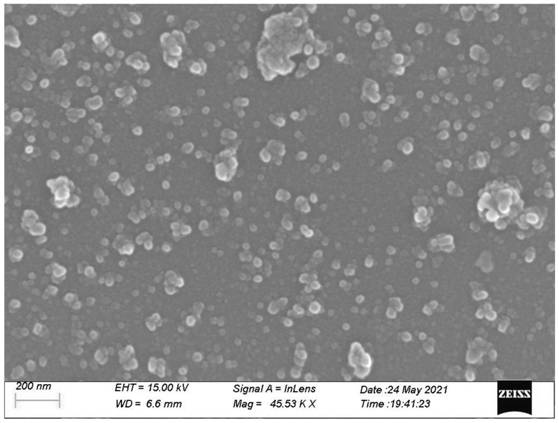

[0032] Step 1: Dissolve 204 mg of tannic acid and 11.83 mg of anhydrous cerium chloride in 10 mL of deionized water. After ultrasonic dissolution, add 500 μL of ammonia water, 625 μL of hydrazine hydrate, and 3.875 mL of absolute ethanol to obtain a mixed solution.

[0033] Step 2: Add the solution mixed in step 1 into the liner of the polytetrafluoroethylene-lined hydrothermal reaction kettle, put it on the hydrothermal reaction kettle high-pressure tank, and put it in an oven at 180°C for 10 hours to react.

[0034] Step 3: After the reaction is completed, cool to room temperature, transfer the solution to a 50mL centrifuge tube, filter with a 0.22μM filter membrane, transfer the filtered solution to a 1000D dialysis bag, and transfer it to a tube filled with deionized water. Dialyze in a 2L beaker for 8 hours. After the dialysis, transfer the solution in the dialysis bag to a 50mL centrifuge tube, freeze it with liquid nitrogen, and then put it into a lyophilizer for freeze-...

Embodiment 2

[0050] Step 1: Dissolve 204 mg of tannic acid and 5.915 mg of anhydrous cerium chloride in 10 mL of deionized water. After ultrasonic dissolution, add 500 μL of ammonia water, 625 μL of hydrazine hydrate, and 3.875 mL of absolute ethanol to obtain a mixed solution.

[0051] Step 2: Add the solution mixed in step 1 into the liner of the polytetrafluoroethylene-lined hydrothermal reaction kettle, put it on the hydrothermal reaction kettle high-pressure tank, and put it in an oven at 180°C for 10 hours to react.

[0052] Step 3: After the reaction is completed, cool to room temperature, transfer the solution to a 50mL centrifuge tube, filter with a 0.22μM filter membrane, transfer the filtered solution to a 1000D dialysis bag, and transfer it to a tube filled with deionized water. Dialyze in a 2L beaker for 8 hours. After the dialysis, transfer the solution in the dialysis bag to a 50mL centrifuge tube, freeze it with liquid nitrogen, and then put it into a lyophilizer for freeze-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com