High-ductility cement-based material for repairing hydraulic outlet works, and preparation method thereof

A technology for drainage buildings and cement-based materials, which is applied in the field of materials, can solve the problems of repairing layer opening, repairing layer swelling, repairing layer damage, etc., and achieves wide source of raw materials, high impact and wear resistance The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

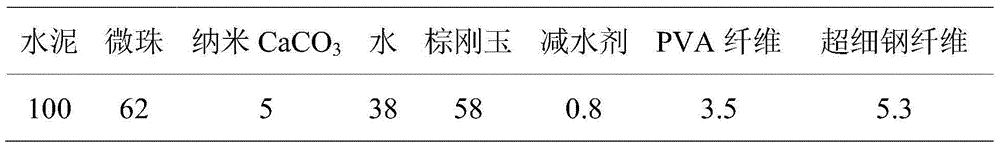

[0034] The composition ratio of materials is shown in Table 1:

[0035] Table 1 Mixing ratio of repairing materials for hydraulic drainage structures (mass parts)

[0036]

[0037] The raw materials used are:

[0038] The cement is P O42.5 cement, the maximum particle size of brown corundum is 0.5mm, and the volume average diameter D(4,3) of microbeads is 95nm; nano-CaCO 3 The average volume diameter D(4,3) of the polycarboxylate superplasticizer is 24.5nm, the water reducing rate is 30%, the equivalent diameter of the chopped PVA fiber is 40μm, and the tensile strength is 1550MPa.

[0039] The elastic modulus is 39GPa; the equivalent diameter of ultra-fine steel fibers is 0.16mm, and the aspect ratio is 50.

[0040] The mixing process of repairing materials for hydraulic drainage structures is as follows:

[0041] (1) First mix cement, microbeads, and nano-CaCO 3 , Pour the brown corundum into the blender and stir for 3 minutes.

[0042] (2) Add water reducer and wate...

Embodiment 2

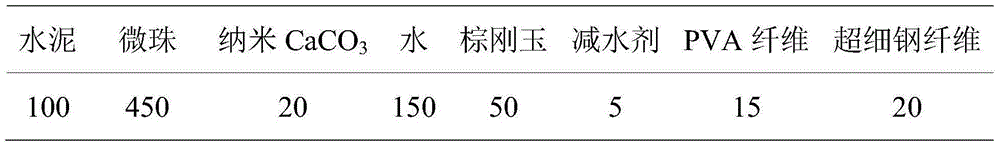

[0050] The composition ratio of materials is shown in Table 2:

[0051] Table 2 Mixing ratio of hydraulic drainage building repair materials (mass parts)

[0052]

[0053] The raw materials used are:

[0054] The cement is P·O52.5 cement, the maximum particle size of brown corundum is 1.25mm, and the volume average diameter of microbeads D(4,3) is 100nm; nano-CaCO 3 The volume average diameter D(4,3) is 24.5nm, polycarboxylate high-performance water reducing agent, water reducing rate is 25%, equivalent diameter of chopped PVA fiber is 40μm, tensile strength is 1550MPa, elastic modulus is 39GPa; ultrafine The steel fiber equivalent diameter is 0.10 mm, and the aspect ratio is 60.

[0055] The mixing process of repairing materials for hydraulic drainage structures is as follows:

[0056] (1) First mix cement, microbeads, and nano-CaCO 3 , Pour the brown corundum into the blender and stir for 3 minutes.

[0057](2) Add water reducer and water, stir for 3 minutes to obtai...

Embodiment 3

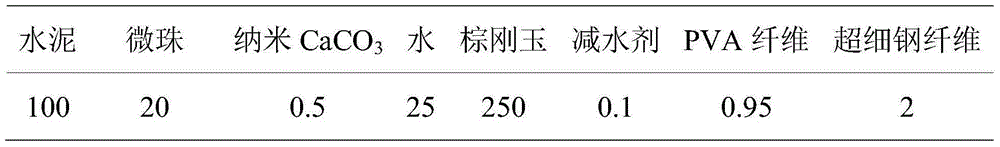

[0065] The composition ratio of materials is shown in Table 3:

[0066] Table 3 Mixing ratio of repairing materials for hydraulic drainage structures (mass parts)

[0067]

[0068] The raw materials used are:

[0069] The cement is P·O42.5 cement, the maximum particle size of brown corundum is 1.5mm, and the volume average diameter D(4,3) of microbeads is 90nm; nano-CaCO 3 The volume average diameter D(4,3) is 25nm, polycarboxylate high-performance water reducing agent, water reducing rate is 40%, chopped PVA fiber equivalent diameter is 40μm, tensile strength is 1550MPa, elastic modulus is 39GPa; ultra-fine steel The fiber equivalent diameter is 0.20 mm, and the aspect ratio is 65.

[0070] The mixing process of repairing materials for hydraulic drainage structures is as follows:

[0071] (1) First mix cement, microbeads, and nano-CaCO 3 , Pour the brown corundum into the blender and stir for 3 minutes.

[0072] (2) Add water reducer and water, stir for 3 minutes to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com