Novel oxazolidine, preparation method, application, and mono-component polyurethane waterproof paint

A polyurethane waterproof and oxazolidine technology, applied in the field of polyurethane additives, can solve problems such as bubbles, achieve uniform dispersion, improve stability, and eliminate bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

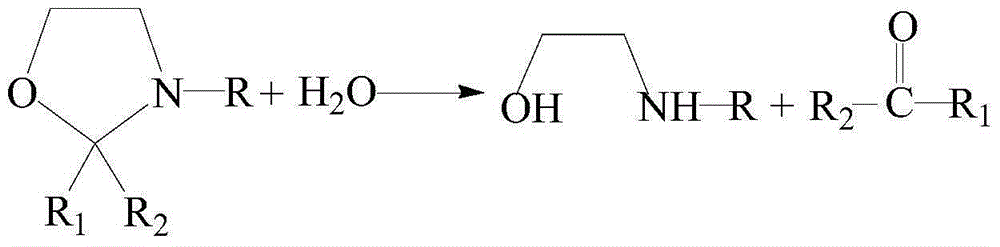

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment provides a kind of preparation method of novel oxazolidine, comprises the following steps:

[0049] (1) 20 mass parts of 2-fluorobenzaldehyde and 50 mass parts of organic solvent N,N-dimethylformamide are mixed, then 20 mass parts of oxazolidine, 30 mass parts of the first catalyst carbonic acid Potassium, reacted at 130°C for 10 hours to obtain 2-(3-oxazolidinyl)benzaldehyde;

[0050] (2) 2-(3-oxazolidinyl) benzaldehyde of 20 mass parts, the second catalyst scandium trifluoromethanesulfonate of 5 mass parts, the first organic solvent dichloroethane of 400 mass parts are mixed, in Reaction at 80°C for 10 hours to obtain benzoxazinooxazolidine;

[0051] (3) The benzoxazinoxazolidine of 10 mass parts, the second organic solvent dichloroethane of 100 mass parts are mixed, add methyl Grignard reagent, Grignard reaction takes place, the temperature of Grignard reaction is- At 5°C, a saturated ammonium chloride solution was added to quench the reactio...

Embodiment 2

[0074] The present embodiment provides a kind of preparation method of novel oxazolidine, comprises the following steps:

[0075] (1) Mix 22 parts by mass of 2-fluorobenzaldehyde with 20 parts by mass of organic solvent N,N-dimethylformamide (DMF), then add 18 parts by mass of oxazolidine, 28 parts by mass of A catalyst, potassium carbonate, was reacted at 150°C for 6 hours to obtain 2-(3-oxazolidinyl)benzaldehyde;

[0076]

[0077] (2) 10 mass parts of 2-(3-oxazolidinyl) benzaldehyde, the second catalyst scandium trifluoromethanesulfonate of 7 mass parts, the first organic solvent dichloroethane (DCE) of 500 mass parts Mix and react at 90°C for 2 hours to obtain benzoxazinoxazolidine;

[0078]

[0079] (3) 12 mass parts of benzoxazinoxazolidine and 50 mass parts of the second organic solvent dichloroethane (DCE) are mixed, and methyl Grignard reagent (methylmagnesium bromide) is added to generate a lattice Grignard reaction, the temperature of the Grignard reaction wa...

Embodiment 3

[0118] The present embodiment provides a kind of preparation method of novel oxazolidine, comprises the following steps:

[0119] (1) 30 mass parts of 2-fluorobenzaldehyde and 10 mass parts of organic solvent N,N-dimethylformamide are mixed, then 12 mass parts of oxazolidine, 25 mass parts of the first catalyst carbonic acid Potassium, reacted at 140°C for 1 hour to obtain 2-(3-oxazolidinyl)benzaldehyde;

[0120] (2) 12 mass parts of 2-(3-oxazolidinyl) benzaldehyde, 6 mass parts of the second catalyst scandium trifluoromethanesulfonate, and 300 mass parts of the first organic solvent benzene are mixed at 100° C. React for 6 hours to obtain benzoxazinoxazolidine;

[0121] (3) The benzoxazinoxazolidine of 15 mass parts, the second organic solvent benzene of 30 mass parts are mixed, add methyl Grignard reagent, Grignard reaction takes place, the temperature of Grignard reaction is 5 ℃, then The reaction was quenched by adding a saturated solution of ammonium chloride to give 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com