Method for preparing high-purity chlorophyll a from spirulina platensis

A technology of spirulina platensis and chlorophyll, which is applied in the field of natural pigments, can solve the problem of low purity of chlorophyll a and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

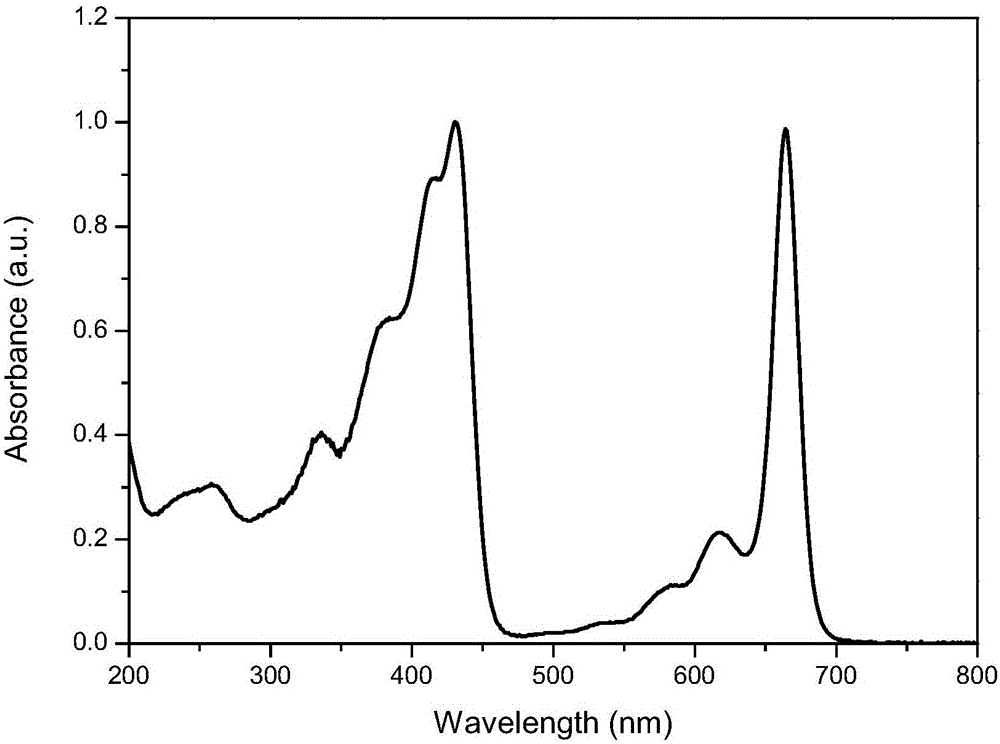

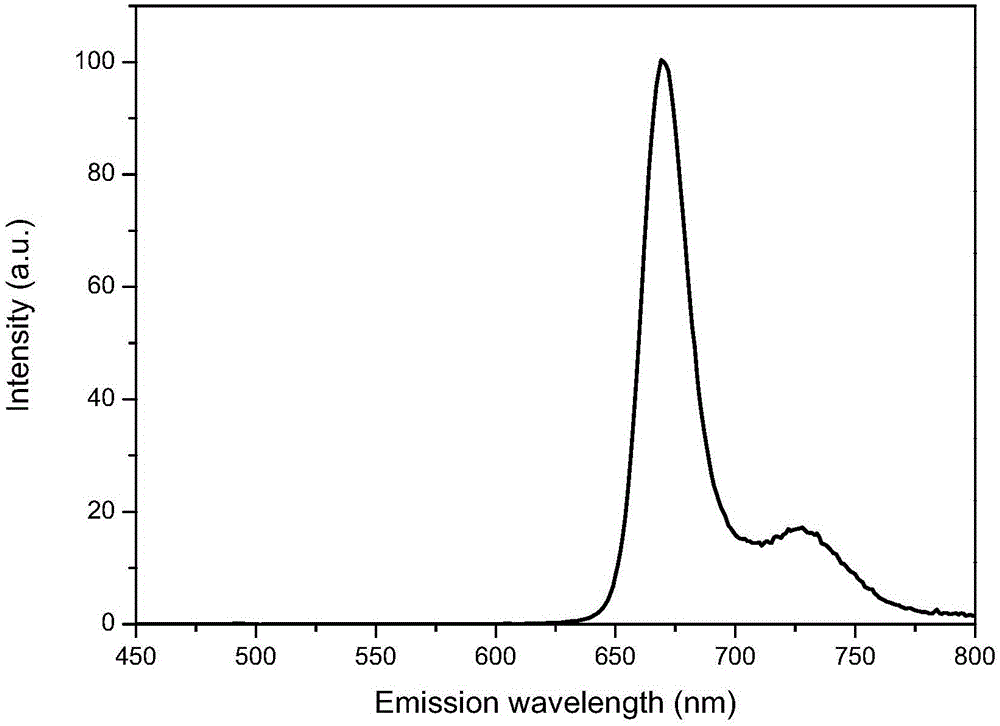

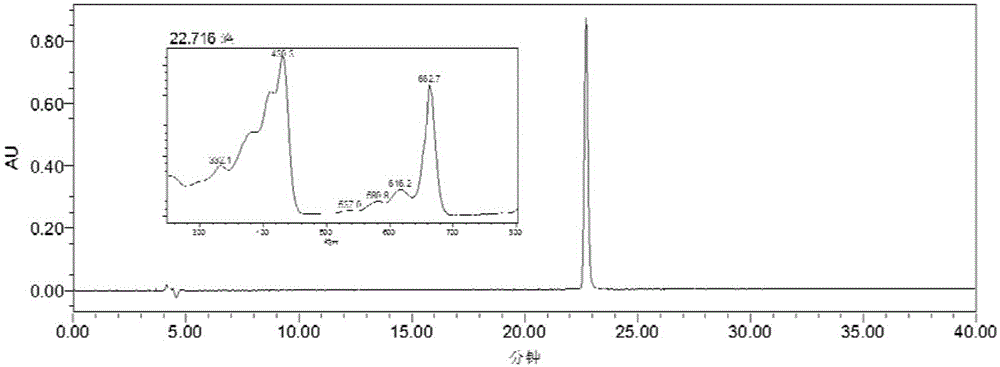

[0025] The concrete steps of the preparation method of high-purity chlorophyll a of the present invention are as follows:

[0026] Take 1 L of Spirulina platensis algae liquid grown to the late logarithmic growth phase, centrifuge and separate the algae, discard the supernatant, enrich the precipitate in a centrifuge tube, and then extract it with 50 mL of ethanol three times, and combine the extracts.

[0027] An appropriate amount of petroleum ether (60-90°C) is added to the extract, water is added until the phases are separated, and the pigment-containing petroleum ether phase is washed twice with water.

[0028] Fill the chromatographic column with 100-200 mesh neutral alumina, first wet the alumina column with 0.3% ethanol petroleum ether solution, then load the sample, and then use 0.3%, 10% ethanol-petroleum ether mixed solvent gradient rinse. The orange-yellow carotenoids are washed out first, followed by the blue-green chlorophyll. The solvent was recovered by rotar...

Embodiment 2

[0030] The concrete steps of the preparation method of high-purity chlorophyll a of the present invention are as follows:

[0031] Take 1 L of Spirulina platensis algae liquid grown to the late logarithmic growth phase, centrifuge and separate the algae, discard the supernatant, enrich the precipitate in a centrifuge tube, and then extract it with 50 mL of ethanol three times, and combine the extracts.

[0032] An appropriate amount of petroleum ether (60-90° C.) was added to the extract, saturated brine was added until the phases were separated, and the pigment-containing petroleum ether phase was washed twice with saturated brine.

[0033] Fill the chromatographic column with 100-200 mesh neutral alumina, first wet the alumina column with 0.3% ethanol petroleum ether solution, then load the sample, and then use 0.3%, 1% ethanol-petroleum ether mixed solvent gradient rinse. The orange-yellow carotenoids are washed out first, followed by the blue-green chlorophyll. The solve...

Embodiment 3

[0035] The concrete steps of the preparation method of high-purity chlorophyll a of the present invention are as follows:

[0036] Take 1 L of Spirulina platensis algae liquid grown to the late logarithmic growth phase, centrifuge and separate the algae, discard the supernatant, enrich the precipitate in a centrifuge tube, and then extract it with 50 mL of ethanol three times, and combine the extracts.

[0037] An appropriate amount of n-hexane is added to the extract, water is added until the phases are separated, and the n-hexane phase containing the pigment is washed twice with water.

[0038] Fill the chromatographic column with 100-200 mesh neutral alumina, first wet the alumina column with 0.3% ethanol-n-hexane solution, then load the sample, and then use 0.3%, 10% ethanol-n-hexane mixed solvent gradient rinse. The orange-yellow carotenoids are washed out first, followed by the blue-green chlorophyll. The solvent was recovered by rotary evaporation to obtain dark green...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com