Ultrasonic wave aided extraction method suitable for high-viscosity collagen

An ultrasonic-assisted extraction and collagen technology, which is applied in the preparation methods of peptides, chemical instruments and methods, and animal/human proteins, etc., can solve the problems of attenuation, unsatisfactory ultrasonic-assisted extraction, and insufficient ultrasonic effect of materials. The effect of reducing extraction cost, preventing damage and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

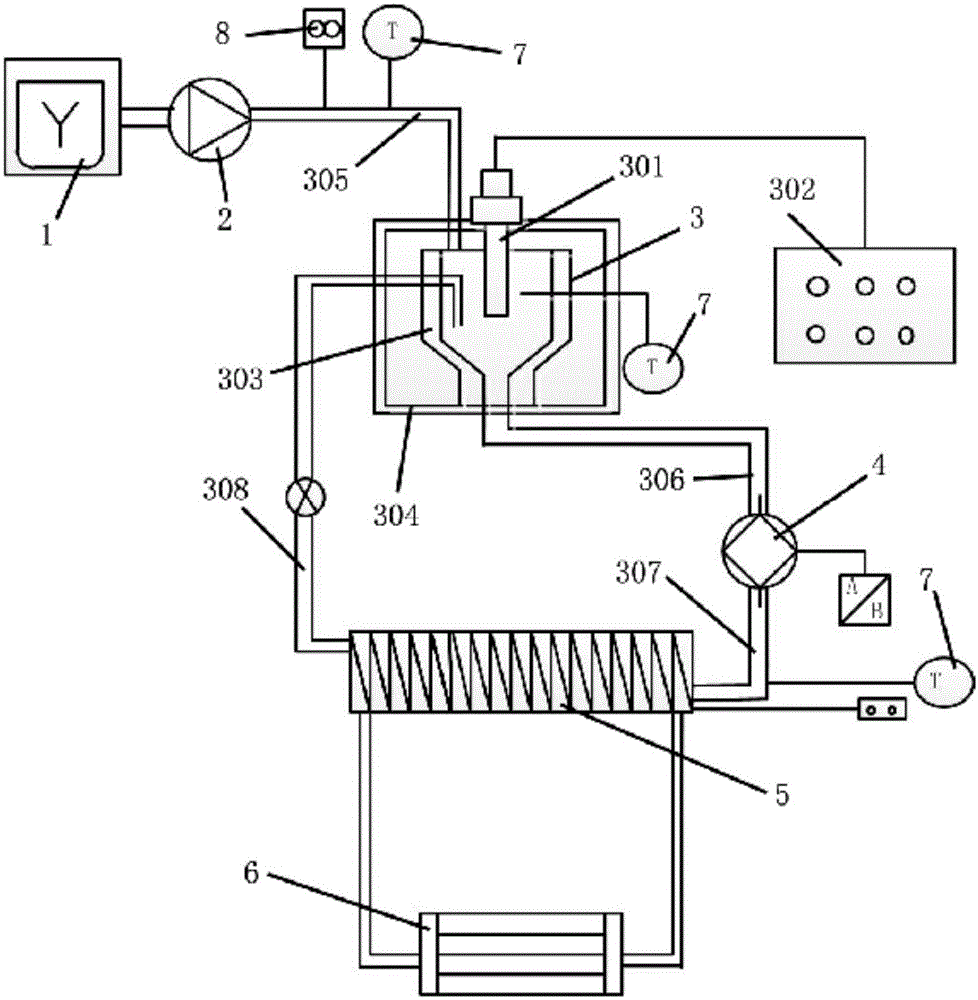

[0033] Such as figure 1 As shown, this ultrasonic-assisted extraction method suitable for high-viscosity collagen is characterized in that it comprises the following steps:

[0034] 1) Soak the material to be extracted in the acidic solution to expand the material to be extracted, and then place the acidic solution soaked in the material to be extracted in the storage mixer 1 for stirring to form a uniform mixed solution;

[0035] 2) Send the mixed solution into the ultrasonic reactor 3 through the feed pump 2, and the ultrasonic reactor 3 performs pulsed ultrasonic treatment on the solution;

[0036] 3) Circulation pump 4 extracts the mixed solution that has been subjected to ultrasonic treatment from the bottom of ultrasonic reactor 3, and the mixed solution is pumped into heat exchanger 5 for cooling;

[0037] 4) After the cooled mixed solution comes out from the heat exchanger 5, it is sent back to the ultrasonic reactor 4 for further ultrasonic treatment;

[0038] 5) Re...

Embodiment 2

[0046] This ultrasonic-assisted extraction method suitable for high-viscosity collagen is the same as Example 1 except for the following technical features:

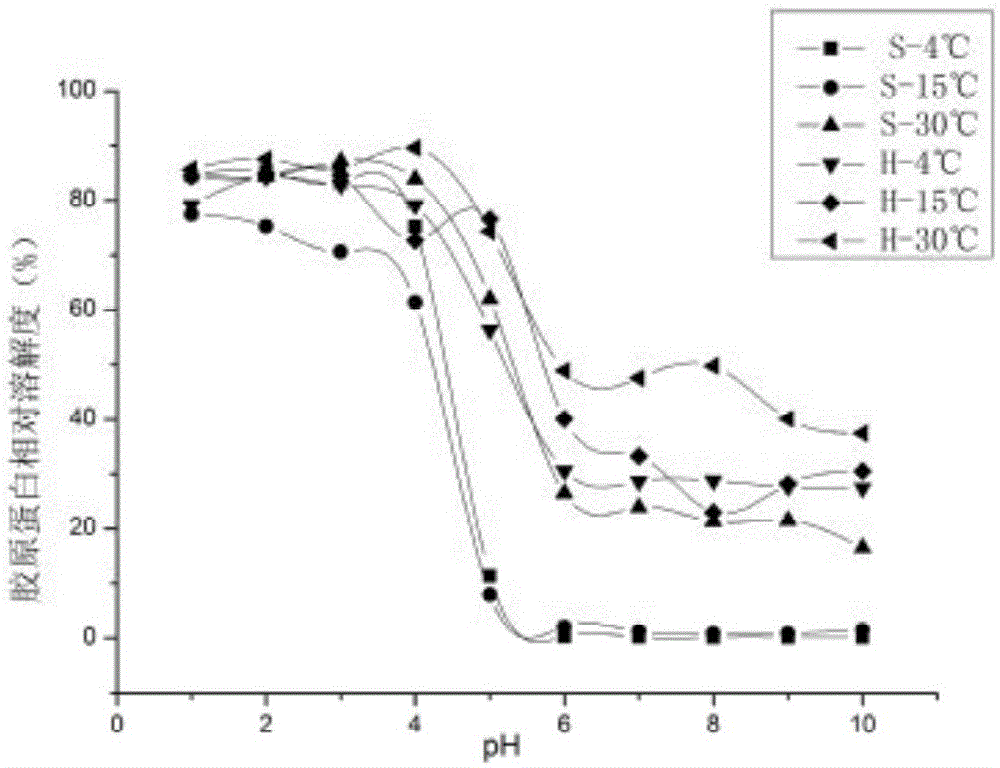

[0047] The parameters of the generator are set to 20kHz, 600W. Soak the material to be extracted in 0.5mol / L acetic acid solution, that is, the acidic solution is acetic acid, and the material to be extracted is fish skin, and the mass ratio of fish skin to acetic acid solution in the mixed solution is 1:20. The volume of the mixed liquid is 1.2L; the time for the reactor to perform the pulsed ultrasonic reaction is 10min to 30min; and the flow rate of the circulating pump to pump the mixed liquid is 150ml / min. The refrigerator makes the temperature of the cold side channel of the heat exchanger 0°C to ensure the mixing of the mixed liquid in the reaction vessel at 4°C. Then the Lowry method was used to measure the dissolution amount of collagen under different ultrasonic-assisted extraction time and the denaturation te...

Embodiment 3

[0052] This ultrasonic-assisted extraction method suitable for high-viscosity collagen is the same as Example 1 except for the following technical features:

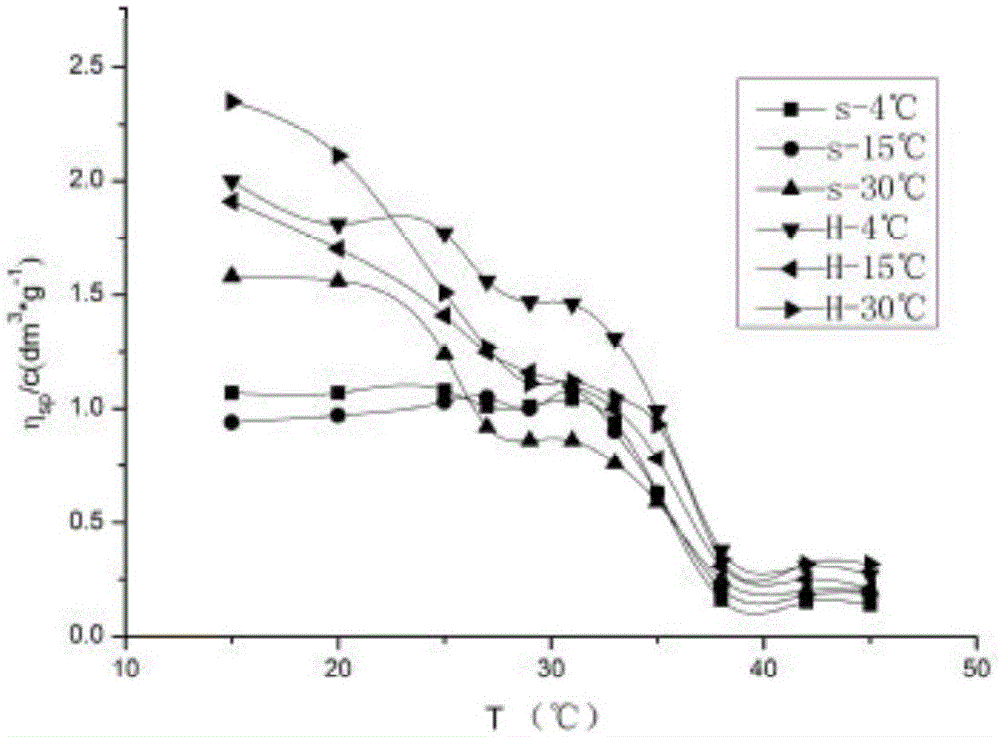

[0053] The parameters of the generator are set to 20kHz, 900W. Soak the material to be extracted in 0.5mol / L acetic acid solution, that is, the acidic solution is acetic acid, and the material to be extracted is fish skin, and the mass ratio of fish skin to acetic acid solution in the mixed solution is 1:20. The volume of the mixed liquid is 1.8L; the time for the reactor to perform pulsed ultrasonic reaction is 30min; and the flow rate of the circulating pump to draw the mixed liquid is 200ml / min. The refrigerator makes the temperatures of the cold side passages of the heat exchanger 0°C, 10°C and 28°C respectively, so as to ensure that the mixed liquids in the reaction vessel are mixed at 4°C, 15°C and 30°C. Measure the solubility and viscosity of collagen after ultrasonic-assisted extraction, use CD (circular dichroi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com