A kind of polybutylene succinate ionomer microporous foam material and preparation method thereof

A technology of polybutylene succinate and microcellular foaming materials, which is applied in the field of polymer materials, can solve the problems of difficult control of cell quality, high cell density, and low material density, and achieve small cell size , The effect of high cell density and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

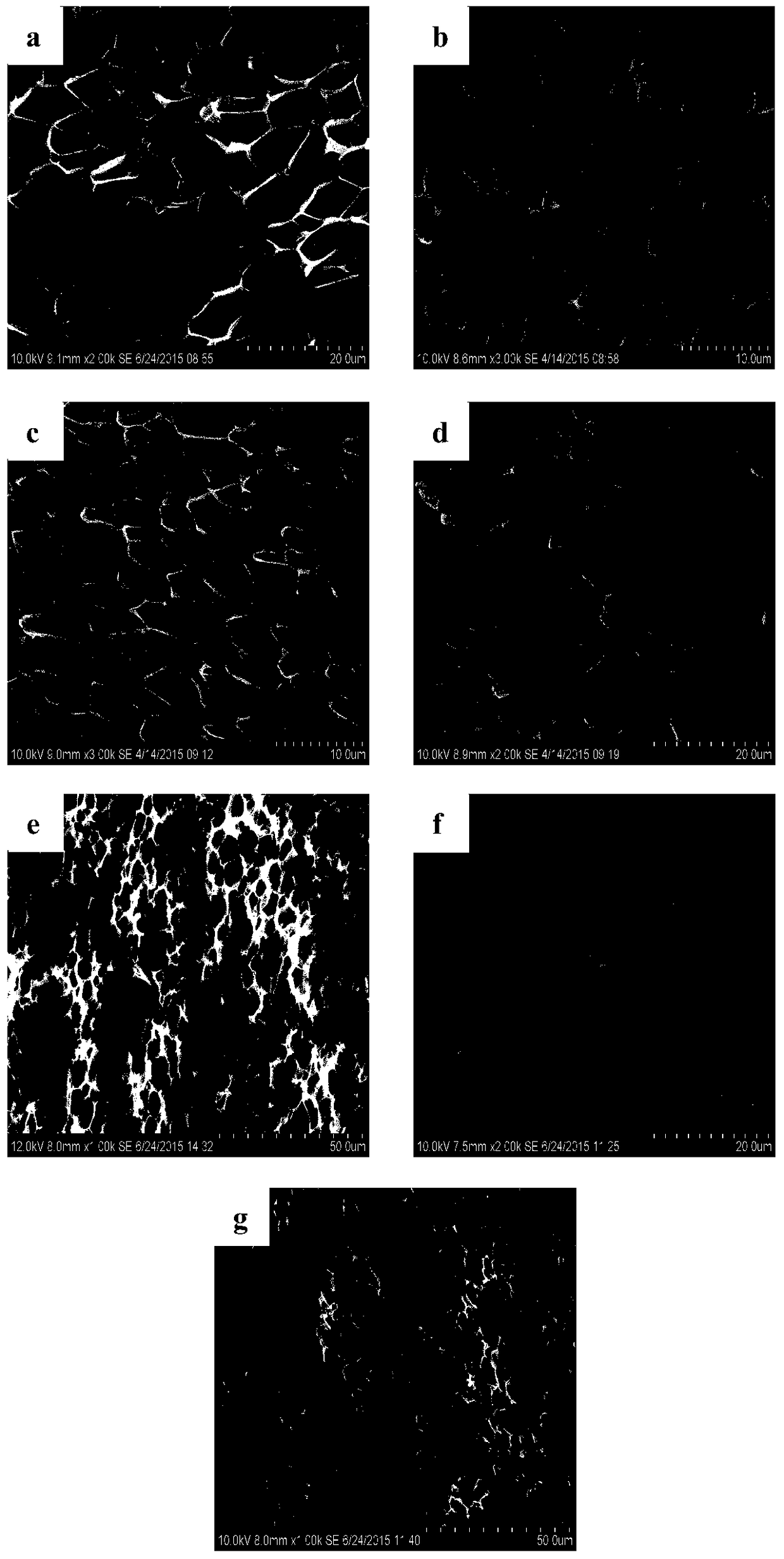

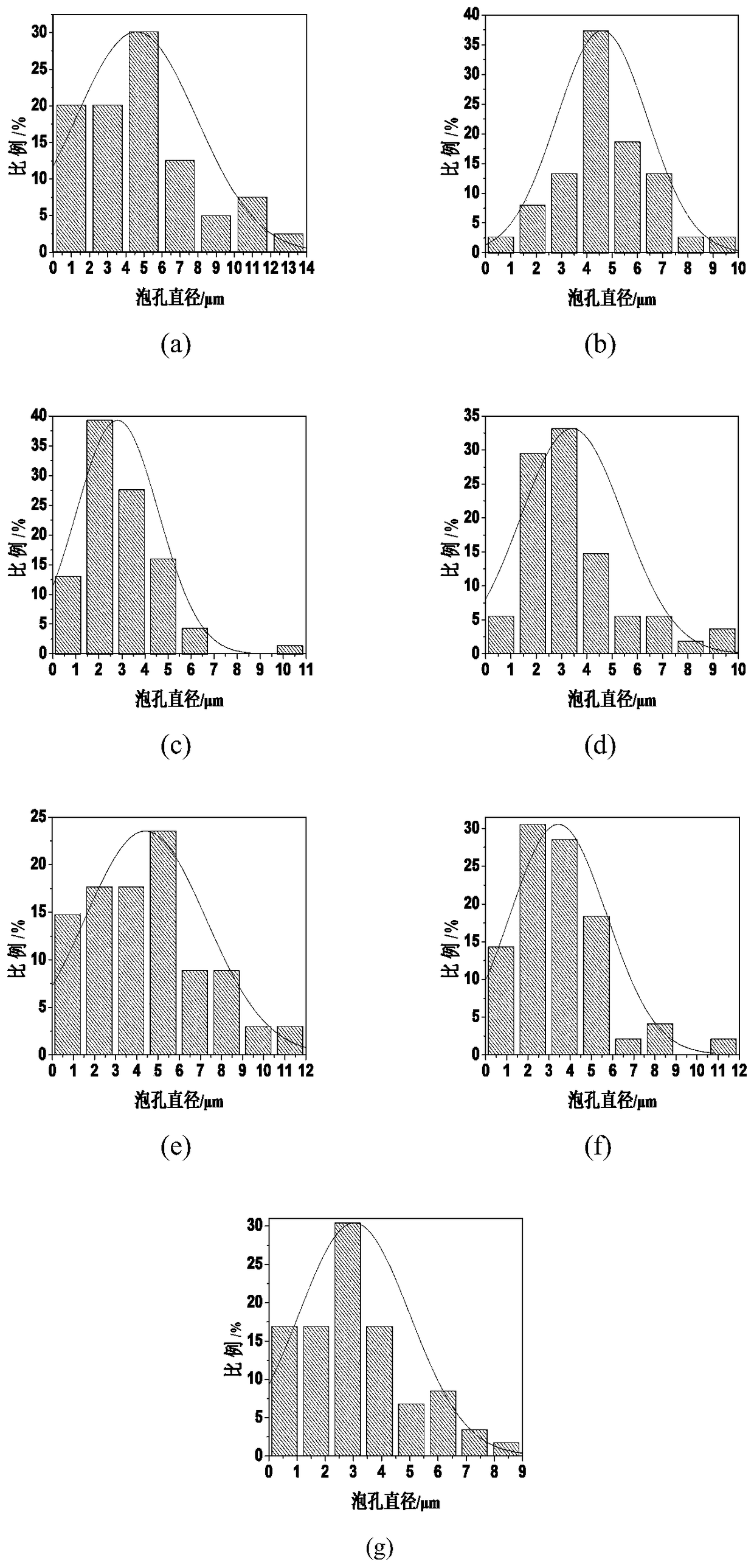

Image

Examples

Embodiment 1

[0031] The polybutylene succinate ionomer with an amino ion content of 1mol% is packed into an autoclave and sealed, the autoclave is heated to 100°C, and the 2 The gas injection system injects CO 2 , purging for 1 to 2 minutes to remove the air in the autoclave, close the pressure relief valve, and control the CO 2 The pressure is 20MPa, keep at constant temperature for 2 hours, then quickly cool down to 80°C, keep at constant temperature for 20 minutes, then quickly release the pressure to normal pressure, and finally cool the autoclave to room temperature to prepare polybutylene succinate Ionomer foam material.

Embodiment 2

[0033] The polybutylene succinate ionomer with an amino ion content of 5 mol% is packed into an autoclave and sealed, and the autoclave is heated to 110° C. 2 The gas injection system injects CO 2 , purging for 1 to 2 minutes to remove the air in the autoclave, close the pressure relief valve, and control the CO 2 The pressure is 25MPa, keep at constant temperature for 2 hours, then quickly cool down to 80°C, keep at constant temperature for 20 minutes, then quickly release the pressure to normal pressure, and finally cool the autoclave to room temperature to prepare polybutylene succinate Ionomer foam material.

Embodiment 3

[0035] The polybutylene succinate ionomer with an amino ion content of 1mol% is packed into an autoclave and sealed, the autoclave is heated to 120°C, and the 2 The gas injection system injects CO 2 , purging for 1 to 2 minutes to remove the air in the autoclave, close the pressure relief valve, and control the CO 2 The pressure is 25MPa, keep at constant temperature for 2 hours, then quickly cool down to 80°C, keep at constant temperature for 20 minutes, then quickly release the pressure to normal pressure, and finally cool the autoclave to room temperature to prepare polybutylene succinate Ionomer foam material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com