High-strength, abrasion-resistant and tear-resistant cable and preparation method of outer sheath thereof

A tear-resistant, high-strength technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of large specific surface area, high surface amino content, and difficulty in dispersion of aramid pulp fibers, so as to improve mechanical properties and improve interface. The effect of binding force, enhancing dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

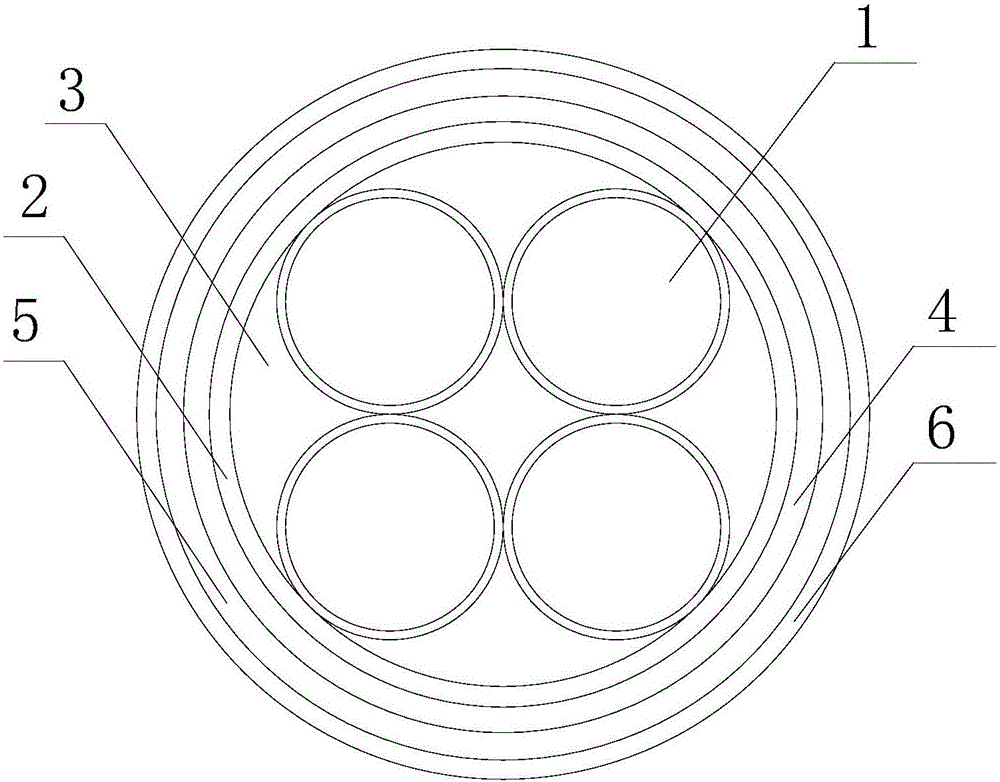

[0018] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a high-strength wear-resistant and tear-resistant cable proposed by the present invention.

[0019] refer to figure 1 , a high-strength wear-resistant and tear-resistant cable proposed by the present invention includes a cable core, and the cable core is formed by twisting four insulated cores 1 with each other, and each insulated core 1 includes a conductor and a wire coated outside the conductor The insulating layer, the inner sheath 2 is wrapped outside the cable core, the flame retardant filling material 3 is filled between the cable core and the inner sheath 2, and the inner sheath 2 is covered with a shielding layer 4, a wrapping layer 5 and an outer sheath in turn. Set of 6;

[0020] The raw materials of the outer sheath 6 include by weight: 55 parts of styrene-butadiene rubber, 22 parts of natural rubber, 22 parts of prefabricated aramid pulp rubber, 14 parts of chloroprene rubber, 1....

Embodiment 2

[0024] A high-strength wear-resistant and tear-resistant cable proposed by the present invention includes a cable core, and the cable core is formed by twisting four insulated cores 1 with each other, and each insulated core 1 includes a conductor and an insulation layer coated outside the conductor The inner sheath 2 is wrapped outside the cable core, the flame retardant filling material 3 is filled between the cable core and the inner sheath 2, and the inner sheath 2 is covered with a shielding layer 4, a wrapping layer 5 and an outer sheath in turn 6;

[0025] The raw materials of the outer sheath 6 include by weight: 50 parts of styrene-butadiene rubber, 25 parts of natural rubber, 20 parts of prefabricated aramid pulp rubber, 18 parts of chloroprene rubber, 0.7 parts of sulfur powder, and 2.2 parts of accelerator AA , 2.3 parts of accelerator MZ, 17 parts of barite powder, 26 parts of carbon black N23426, 10 parts of nanocellulose whiskers, 8 parts of calcite powder, 9 pa...

Embodiment 3

[0029] A high-strength wear-resistant and tear-resistant cable proposed by the present invention includes a cable core, and the cable core is formed by twisting four insulated cores 1 with each other, and each insulated core 1 includes a conductor and an insulation layer coated outside the conductor The inner sheath 2 is wrapped outside the cable core, the flame retardant filling material 3 is filled between the cable core and the inner sheath 2, and the inner sheath 2 is covered with a shielding layer 4, a wrapping layer 5 and an outer sheath in turn 6;

[0030] The raw materials of the outer sheath 6 include by weight: 53 parts of styrene-butadiene rubber, 23 parts of natural rubber, 21 parts of prefabricated aramid pulp rubber, 15 parts of chloroprene rubber, 1 part of sulfur powder, and 1.9 parts of accelerator AA , 2.5 parts of accelerator MZ, 15 parts of barite powder, 8 parts of carbon black N23428, 8 parts of nanocellulose whiskers, 9 parts of calcite powder, 7 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com