Patents

Literature

41results about How to "Improve wear and tear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

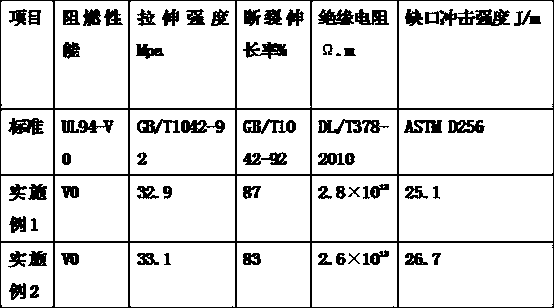

High-strength corrosion resistance distribution box used for electric power

The invention relates to a distribution box, which includes a box body, a box cover, and a fastening mechanism for movably connecting the box body and the box cover. The raw material components of the box body and the box cover are as follows, all in parts by weight: polyethylene resin 40-60 20-30 parts of phenolic resin, 2-10 parts of elastomer, 0.1-15 parts of graphene, 3-7 parts of silicon carbide, 1-10 parts of silane coupling agent, 12-15 parts of semi-reinforced furnace black, calcined 10-12 parts of pottery clay, 6-12 parts of surface-treated Kevlar chopped fibers, 5-7 parts of nanomolybdenum disulfide (MoS2), 0.5-3 parts of aluminum oxide, 3 parts of polydimethylsiloxane ‑5 parts, 0.5‑2.5 parts of flame retardant, 1‑3 parts of dispersant. In the preparation process of the distribution box body and the box cover of the present invention, the raw materials and the proportions, together with the processing technology, make the distribution box box and the box cover of the present invention have excellent flexibility, mechanical properties and corrosion resistance, and at the same time It has good thermal conductivity, improves the performance of the distribution box as a whole, is not easy to age, has sufficient rigidity, and has a long service life, reducing maintenance costs.

Owner:DONGA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

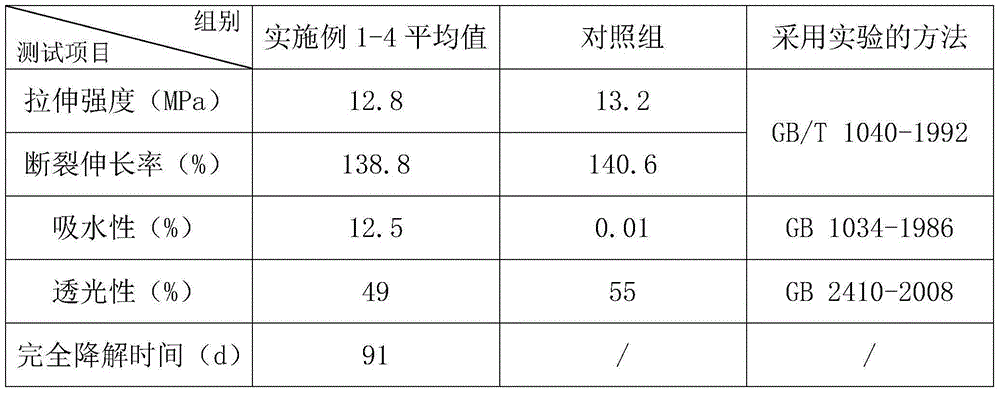

Biodegradable peanut protein plastic

The invention discloses biodegradable peanut protein plastic. The biodegradable peanut protein plastic comprises the following raw materials in parts by weight: 30-35 parts of poly(hydroxybutyate-co-hydroxyvalerate) (PHBV), 55-60 parts of modified poly-beta-hydroxybutyrate (PHB), 15-20 parts of peanut protein powder, 2-2.4 parts of jute fiber, 3-4 parts of silk fiber, 1.1-1.3 parts of a silane coupling agent A-151, 2-3 parts of sodium lactate, 0.5-0.8 part of sodium dehydroacetate, 1.7-2.3 parts of dioctyl terephthalate (DOTP), 2-4 parts of octyl epoxy stearate, 25-28 parts of carbon black N550, 12-16 parts of heavy calcium carbonate, 4-7 parts of kaolin, and 0.7-0.9 part of antioxidant 1076, wherein modified poly-beta-hydroxybutyrate (PHB) is obtained by blending poly-beta-hydroxybutyrate (PHB) with ethylene-propylene rubber for modifying. The biodegradable peanut protein plastic disclosed by the invention can be degraded into low-molecular-weight compounds by virtue of microorganisms and thus the pollution of 'white garbage' can be effectively avoided; the biodegradable peanut protein plastic has the advantages of high degree of flexibility, good impact resistance and oxidation resistance, low water absorption performance and low completely degradation rate and the service life of the biodegradable peanut protein plastic is prolonged.

Owner:广州市炜业塑胶有限公司

Anti-flaming aging-resistant rubber material

The invention discloses an anti-flaming aging-resistant rubber material which comprises the following constituents in parts by weight: 40 parts to 45 parts of butadiene styrene rubber, 30 parts to 36 parts of polyurethane elastomer, 10 parts to 15 parts of chlorinated butyl rubber, 2 parts to 3 parts of vulcanizing agent BPO, 1.2 parts to 1.8 parts of sulphur, 2 parts to 4 parts of divinyl carboxylic acid sodium, 20 parts to 30 parts of calcite powder, 9 parts to 11 parts of kieselguhr, 5 parts to 7 parts of aluminum silicate, 14 parts to 15 parts of carbon black N660, 14 parts to 15 parts of carbon black N330, 10 parts to 12 parts of magnesium hydroxide, 3 parts to 5 parts of quartz powder, 5 parts to 7 parts of zinc oxide, 2 parts to 4 parts of calcium stearate, 5 parts to 8 parts of barium stearate, 5 parts to 7 parts of diphenyl phosphate ester, 2 parts to 4 parts of melamine, and 1.5 parts to 2.5 parts of silane coupling agent KH450. The anti-flaming aging-resistant rubber material has an excellent anti-flaming aging-resistant performance, so that smog is effectively prevented from generating during a combustion process; besides, the ozone resistance and the weather resistance of the anti-flaming aging-resistant rubber material are excellent; moreover, the anti-flaming aging-resistant rubber material further has the advantages of high elasticity, high hardness and high strength.

Owner:南通鹏达体育用品有限公司

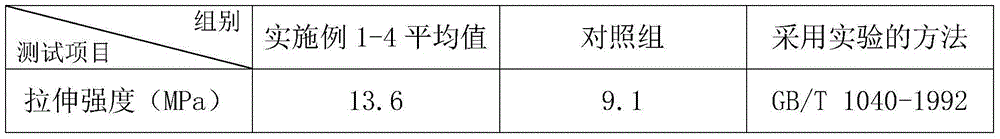

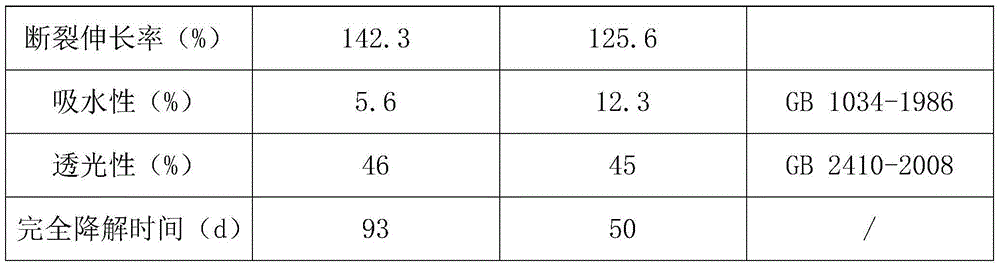

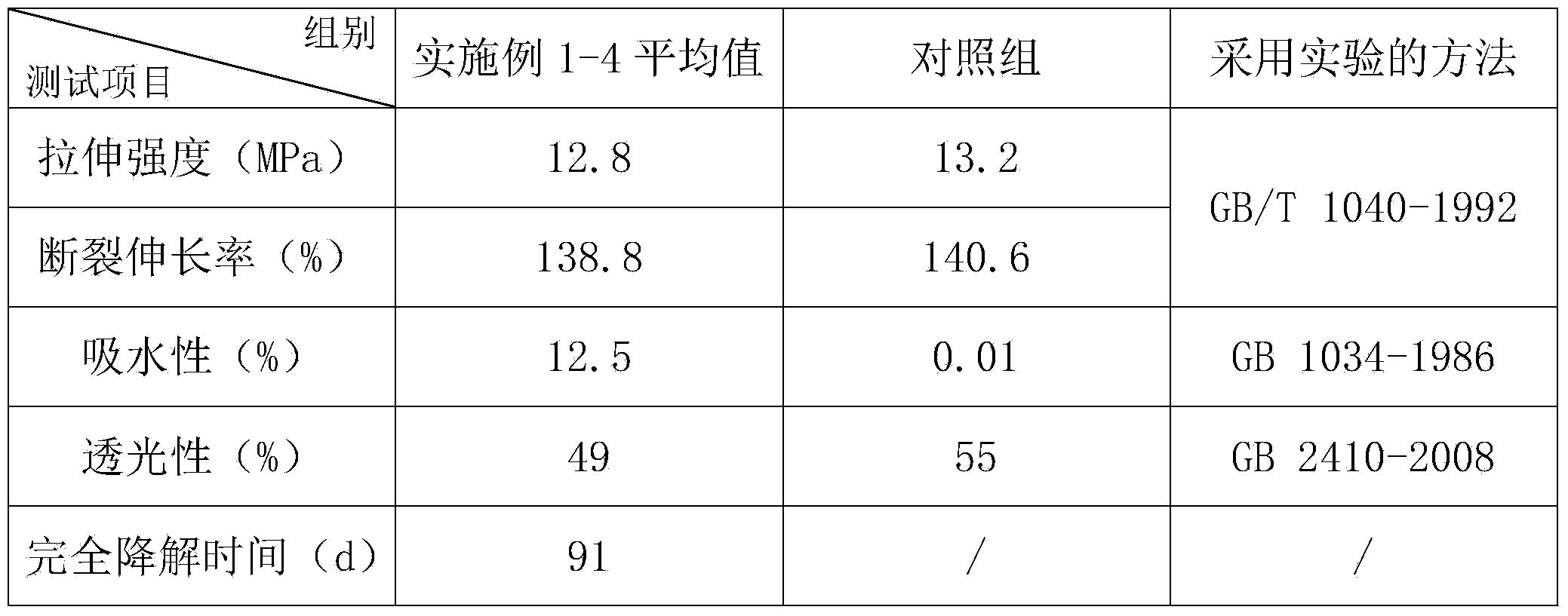

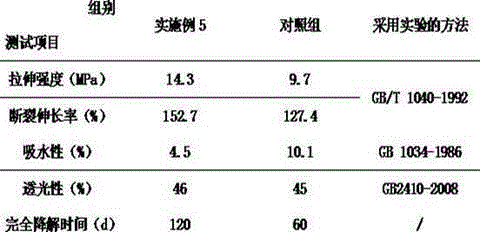

Degradable plastic material

The invention discloses a degradable plastic material. The degradable plastic material comprises the following raw materials in part by weight: 5-50 parts of hydroxybutyrate and valeric acid copolyester PHBV4, 50-55 parts of peanut protein prowder, 15-18 parts of nanometer cellulose whiskers, 12-15 parts of coconut fibers, 3-5 parts of amylase, 1.5-2.2 parts of silane coupling agents, 2-3 parts of potassium sorbate, 2-3 parts of dehydroacetic acids, 1.4-1.6 parts of dioctyl phthalate, 1.2-1.6 parts of zinc stearate, 10-12 parts of hard clay, 5-9 parts of kaolin, 7-11 parts of sepiolite and 1-1.4 parts of 2, 6- di-tert-butyl-4-methylphenol BHT. The degradable plastic material can be completely decomposed into micromolecule substances under effects of microorganisms; the tensile strength, the breakage elongation and the light transmission of the degradable plastic material are close to those of the existing polypropylene; and the degradable plastic material can replace the polypropylene in some fields.

Owner:浙江创新旭隆新材料科技有限公司

High-strength, abrasion-resistant and tear-resistant cable and preparation method of outer sheath thereof

InactiveCN105061842AImprove toughnessImprove wear resistanceRubber insulatorsInsulated cablesEpoxyCalcite

The invention discloses a high-strength, abrasion-resistant and tear-resistant cable. The cable comprises a cable core, wherein an inner sheath covers the cable core, and a shielding layer, a wrapping layer and an outer sheath sequentially cover the inner sheath; the outer sheath comprises raw materials in parts by weight as follows: 50-55 parts of butadiene styrene rubber, 22-25 parts of natural rubber, 20-22 parts of a prefabricated aramid pulp sizing material, 14-18 parts of chloroprene rubber, 0.7-1.1 parts of sulphur powder, 1.8-2.2 parts of an accelerant AA, 2.3-2.6 parts of an accelerant MZ, 14-17 parts of barite powder, 26-29 parts of carbon black N234, 7-10 parts of nano-cellulose whiskers, 8-10 parts of calcite powder, 6-9 parts of kieselguhr, 5-8 parts of aluminum silicate, 2.8-3.2 parts of a mono-alkoxy pyrophosphate type titanate coupling agent, 2.6-3.2 parts of coconut oil, 1.4-1.8 parts of a plasticizer DCHP, 5-7 parts of octyl epoxy stearate, 1.6-2.4 parts of an anti-aging agent H and 1.8-2.5 parts of an anti-aging agent DFC-34.

Owner:繁昌县菲德通讯材料设计有限公司

Stretch-proof wear-resistant oil-resistant modified cable material and preparation method thereof

InactiveCN104231451AGood oil resistanceAccelerated corrosionRubber insulatorsVulcanizationWear resistant

The invention discloses a stretch-proof wear-resistant oil-resistant modified cable material which is prepared from the following raw materials in parts by weight: 8-12 parts of chloroprene rubber, 25-28 parts of hydrogenated butadiene-acrylonitrile rubber, 70-73 parts of an ethylene propylene diene monomer, 17-20 parts of melamine formaldehyde resin, 13-16 parts of pre-treated plant powder, 8-11 parts of aluminum borate crystal whiskers, 2-5 parts of titanium nitride, 4-8 parts of aluminum oxide, 27-30 parts of calcite, 24-27 parts of furnace black, 18-21 parts of quartz powder, 6-8 parts of diethyl phthalate DEP, 3-4 parts of cresyl diphenyl phosphate CDPP, 3.4-5.3 parts of antimonous oxide, 5.3-6.2 parts of red phosphorus capsules, 6-8 parts of a peroxide vulcanization system, 0.4-0.8 part of an antiager D-50 and 1.2-1.8 parts of an antiager SP. The invention further discloses a preparation method of the stretch-proof wear-resistant modified cable material.

Owner:ANHUI LAND GRP

Protein plastic material

The invention discloses a protein plastic material comprising the following raw materials in parts by weight: 45-50 parts of PBS (poly butylenes succinate), 30-35 parts of poly-beta-hydroxybutyric acid (PHB), 20-25 parts of peanut protein powder, 2.5-3 parts of potassium titanate fiber, 5-7 parts of silk fiber, 1.2-1.7 parts of a silane coupling agent KH570, 2-3 parts of sodium sorbate, 1.1-1.6 parts of ethyl p-hydroxybenzoate, 1.7-1.9 parts of diisooctyl phthalate (DIOP), 3-6 parts of epoxidized soybean oil, 3-5 parts of starch acetate, 15-18 parts of talcum powder, 7-11 parts of wollastonite powder, 5-9 parts of calcite powder and 1-1.4 parts of tert-butylhydroquinone (TBHQ). The protein plastic material disclosed by the invention can be decomposed by microorganisms, and is strong in ductility and good in impact resistance and oxidation resistance, the generation of white pollution can be avoided and the consumption of agricultural product resources can also be reduced.

Owner:威海正森新材料科技有限公司

Modified environmental protection plastic with high ductility, impact resistance and oxidation resistance

The invention discloses modified environmental protection plastic with high ductility, impact resistance and oxidation resistance. The modified environmental protection plastic comprises the following raw materials in parts by weight: 45-50 parts of poly butylenes succinate (PBS), 30-35 parts of poly-beta-hydroxybutyric acid (PHB), 20-25 parts of peanut protein powder, 2.5-3 parts of potassium titanate fiber, 12-15 parts of coconut fiber, 1.2-1.7 parts of a silane coupling agent KH570, 2-3 parts of sodium sorbate, 1.1-1.6 parts of ethyl p-hydroxybenzoate, 1.4-1.6 parts of dioctyl phthalate (DOP), 1,2-1.6 parts of zinc stearate, 3-5 parts of starch acetate, 15-18 parts of talcum powder, 7-11 parts of wollastonite powder, 5-9 parts of calcite powder, 7-11 parts of sepiolite,1-1.4 parts of tertiary butyl hydroquinone (TBHQ) and 1-1.4 parts of 2,6-di-tert-butyl-4-methylphenol (BHT). The modified environmental protection plastic disclosed by the invention can be decomposed by microorganisms and is high in ductility and good in impact resistance and oxidation resistance.

Owner:珠海市安迪尔生物科技有限公司

Environment-friendly polyhydroxybutyrate-hydroxyvalerate plastic material

The invention discloses an environment-friendly polyhydroxybutyrate-hydroxyvalerate plastic material. The environment-friendly polyhydroxybutyrate-hydroxyvalerate plastic material is composed of raw materials including, by weight part, 20-30 parts of corn starch, 10-13 parts of polyvinyl alcohol solution, 1-1.5 parts of glyoxal water solution, 7-10 parts of cashew phenolic resin, 22-24 parts of polyhydroxybutyrate-hydroxyvalerate, 8-10 parts of cellulose nanocrystal, 1.5-2 parts of silane coupling agent, 1.5-2.5 parts of dehydroacetic acid, 1.8-2.3 parts of ethyl p-hydroxybenzoate, 2-2.5 parts of di-2-ethylhexyl phthalate, 1-1.5 parts of urea, 1.8-2.5 parts of zinc stearate, 6-7 parts of epoxidized soybean oil, 8-10 parts of silk fiber, 8-10 parts of starch acetate, 15-18 parts of hard argil, 15-20 parts of talcum powder, 8-12 parts of kaolin, 8-10 parts of sepiolite, 1.5-2.5 parts of tert-butylhydroquinone, 1-1.4 parts of 2,6-di-tert-butyl-4-methylphenol, 15-18 parts of isopropanol and 16-20 parts of water.

Owner:中山崇高玩具制品厂有限公司

Modified environment-friendly plastic with high elasticity

The invention discloses a modified environment-friendly plastic with high elasticity. The modified environment-friendly plastic comprises the following raw materials in parts by weight: 50-60 parts of ethylene-vinyl acetate copolymer, 45-55 parts of polyethylene resin, 18-22 parts of hydroxybutyrate-hydroxyvalerate copolyester, 12-15 parts of modified poly-beta-hydroxybutyric acid, 15-20 parts of oxidized starch, 10-15 parts of styrene-butadiene-styrene block copolymer, 1.5-1.8 parts of carbon fibers, 3-4 parts of cotton fibers, 1.1-1.3 parts of silane coupling agent, 2-3 parts of methylparaben, 1.1-1.6 parts of potassium sorbate, 2-2.2 parts of epoxy fatty acid octyl ester, 5-7 parts of tricresyl phosphate, 6-8 parts of precipitated barium sulfate, 3-5 parts of calcined kaolin, 23-26 parts of fumed titania and 1-1.4 parts of antioxidant. The modified environment-friendly plastic has high elasticity and excellent tensile strength, elongation at break and thermal aging property and can not cause irreversible harms to the environment.

Owner:ZIBO KUAKE MEDICINE TECH

Wear-resisting anti-slipping electrician ladder for electric power construction

InactiveCN106046507AImprove impact resistanceImprove wear resistanceLaddersAgricultural engineeringWear resistance

The invention relates to a wear-resisting anti-slipping electrician ladder for electric power construction. The wear-resisting anti-slipping electrician ladder comprises two ladder legs and a pedal plate connected between the two ladder legs; rubber anti-slipping sleeves sleeve the tops of the ladder legs; hooks and containing barrels are arranged at the two sides of the upper parts of the ladder legs respectively; the ladder legs are made of bamboo; the pedal plate is made of high-strength wear-resisting plastic. The pedal plate provided by the invention has good heat dissipation performance, the safety of the ladder is guaranteed, and the service life is prolonged; the ladder is not easy to age, enough in rigidity and long in service life; the maintenance cost is reduced and the ladder is firm and durable on the basis of guaranteeing portability. The rubber anti-slipping sleeves enhance the wearing resistance, so that the anti-slipping performance of the rubber anti-slipping sleeves is enhanced.

Owner:郭秀珍

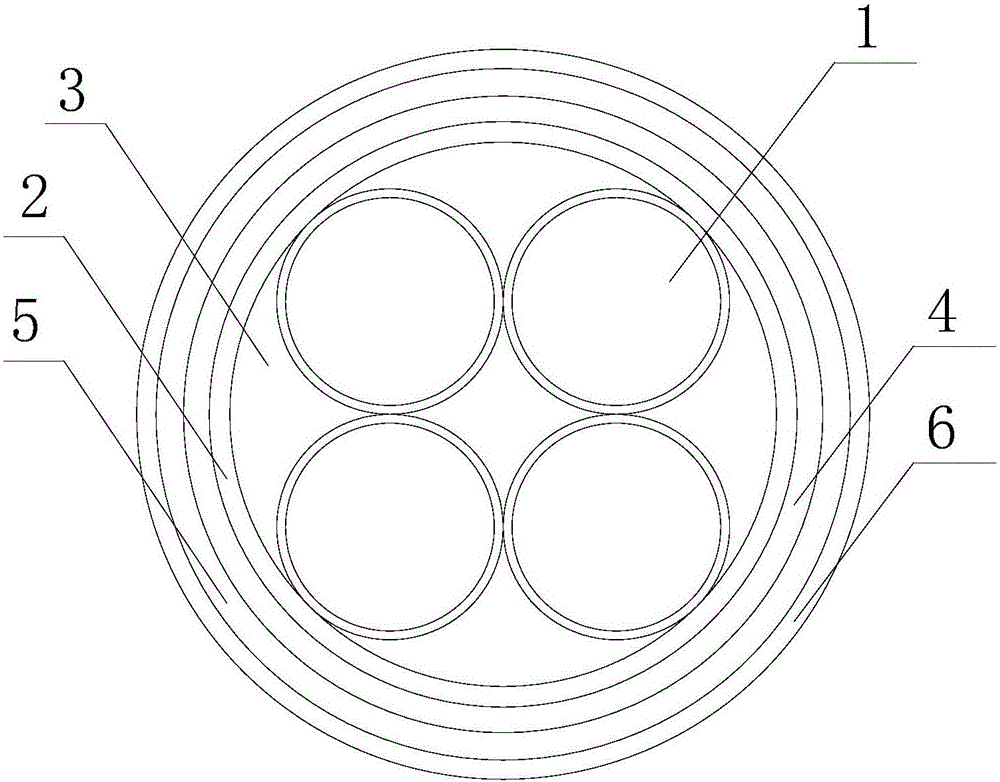

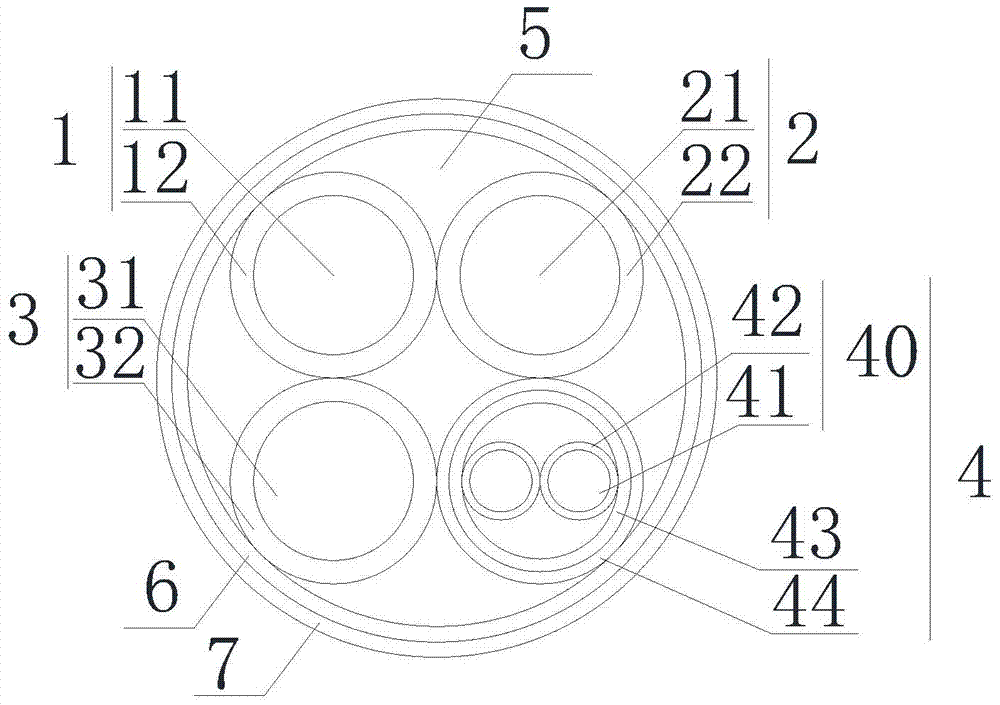

Electrical-vehicle charging pile cable capable of transmitting temperature measurement and control signals

ActiveCN104332237AImprove insulation performanceHigh hardnessPower cables with screens/conductive layersInsulated cablesTemperature controlElectrical conductor

The invention discloses an electrical-vehicle charging pile cable capable of transmitting temperature measurement and control signals. The cable includes a cable core which includes a live wire core, a null line core, a ground wire core and a temperature control wire core, wherein the live wire core includes a live wire conductor and a first insulating layer which wraps externally the live wire conductor; the null line core includes a null line conductor and a second insulating layer which wraps externally the null line conductor; the ground wire core includes a ground wire conductor and a third insulating layer which wraps externally the ground wire conductor; the temperature control wire core includes two signals transmission lines and each signal transmission line includes a temperature control conductor and a forth insulating layer which wraps externally the temperature control conductor; the two signal transmission lines are externally wrapped sequentially with a metal wrapping tape shielding layer and a metal braiding shielding layer after being mutually stranded; the cable core is externally wrapped with a wrapping tape layer in a lapping manner; and the wrapping tape layer is externally wrapped with an outer protection layer in a pressing manner. The temperatures of the cable and a plug can be monitored in a real-time manner in a charging process and the power supply can be cut off timely when the temperature of the plug is too high so that it is prevented that overheat causes a fire disaster.

Owner:安徽国宾光电股份有限公司

Environment-friendly polycaprolactone plastic material

ActiveCN104312115AGood flexibilityReasonable control of the amount addedAntioxidantPolyvinyl alcohol

The invention discloses an environment-friendly polycaprolactone plastic material which is prepared from the following raw materials in parts by weight: 8-12 parts of starch, 15-20 parts of polyvinyl alcohol solution, 0.8-1.3 parts of glyoxal water solution, 5-10 parts of tung oil, 30-40 parts of polycaprolactone, 8-12 parts of potassium titanate, 1.5-2 parts of gamma-(methylacryloyloxy)propyltrimethoxy silane, 1.5-2 parts of ethyl p-hydroxybenzoate, 1.8-2.2 parts of diisononyl phthalate, 1-1.5 parts of urea, 5-8 parts of butyl epoxy tall oil ester, 5-7 parts of jute fiber, 6-7 parts of oxidized starch, 22-24 parts of meerschaum powder, 1.5-2.2 parts of tert-butyl hydroquinone, 15-18 parts of ethylene glycol, 12-16 parts of water, 1.5-2.2 parts of sodium lactate, 1.4-1.5 parts of sodium diacetate and 1.5-2 parts of antioxidant 1010. The environment-friendly polycaprolactone plastic material has the advantages of favorable biodegradability, environment friendliness, excellent aging resistance, excellent water resistance and favorable mechanical properties.

Owner:广东中凯塑业有限公司

Cable sheath material resistant to seawater corrosion

InactiveCN108341999AReasonable ratio of ingredientsImprove anti-agingRubber insulatorsCross-linked polyethyleneChemical stability

The invention relates to the field of polymer materials, in particular to a cable sheath material resistant to seawater corrosion. The cable sheath material resistant to seawater corrosion is composedof the following raw materials: in parts by weight, 30-50 parts of modified polytetrafluoroethylene, 8-15 parts of aluminum bronze, 45-70 parts of nitrile rubber, 3-9 parts of ceramsite, 12-18 partsof glass fiber, 15-22 parts of phenolic resin, 5-11 parts of silica sol, 10-18 parts of crosslinked polyethylene, 2-6 parts of alumina ceramic powder, 0.3-1.7 parts of potassium titanate whisker, 11-17 parts of silicone, 1-6 parts of epoxidized soybean oil and 1-8 parts of a silane coupling agent. The cable sheath material resistant to seawater corrosion has reasonable component ratios, excellentchemical stability, excellent corrosion resistance, excellent anti-aging performance, high yield, high hardness, good wear resistance and long service life.

Owner:ANHUI DUJIANG CABLE GROUP

Modified environment-friendly plastic with high mechanical properties

The invention discloses modified environment-friendly plastic with high mechanical properties. The modified environment-friendly plastic comprises the following raw materials in parts by weight: 75-85 parts of polycarbonate resin, 22-28 parts of acrylonitrile-butadiene-styrene, 18-22 parts of polycaprolactone, 25-30 parts of poly(3-hydroxybutyrate-co-3-hydroxyvalerate), 13-18 parts of ethylene-vinyl acetate copolymers, 10-15 parts of glass beads, 3-4 parts of bastose, 1.5-1.8 parts of a titanate coupling agent, 2-3 parts of methyl p-hydroxybenzoate, 1.1-1.6 parts of potassium sorbate, 2-2.2 parts of diisononyl phthalate, 5-7 parts of tricresyl phosphate, 6-8 parts of heavy calcium carbonate, 3-5 parts of diatomite, 23-26 parts of calcined kaolin and 1-1.4 parts of an anti-aging agent. The modified environment-friendly plastic has high mechanical properties, is excellent in tensile strength and elongation at break, can be degraded into carbon dioxide and water by microorganisms, can be recycled by the natural world and cannot generate irreversible damage to the environment.

Owner:ZIBO KUAKE MEDICINE TECH

Environment-friendly poly-beta-hydroxybutyric acid plastic material

The invention discloses an environment-friendly poly-beta-hydroxybutyric acid plastic material. The environment-friendly poly-beta-hydroxybutyric acid plastic material is composed of raw materials including, by weight part, 15-20 parts of corn starch, 8-12 parts of 5-7% polyvinyl alcohol solution, 0.5-0.8 part of 25-35% crosslinking agent and glycol water solution, 8-12 parts of cashew phenolic resin, 25-30 parts of poly-beta-hydroxybutyric acid, 5-8 parts of potassium titanate fiber, 2-3 parts of gamma-(methylacryloyl oxygen) methyl propyl trimethoxy silane, 2-2.5 parts of ethyl p-hydroxybenzoate, 1.5-2 parts of di-2-ethylhexyl phthalate, 0.5-0.8 part of urea, 5-8 parts of epoxidized soybean oil, 4-8 parts of silk fiber, 5-8 parts of starch acetate, 20-25 parts of talcum powder, 15-20 parts of calcite powder, 2-2.5 parts of tert-butylhydroquinone, 20-25 parts of glycerol and 15-18 parts of distilled water. The environment-friendly poly-beta-hydroxybutyric acid plastic material is environmentally friendly, high in biodegradation performance and waterproof performance and excellent in ageing-resistant performance and mechanical performance.

Owner:GUANGDONG KAIYU SCI & EDUCATION CULTURE CO LTD

Flame-retardant environment-friendly foamed plastic

The invention discloses a flame-retardant environment-friendly foamed plastic which comprises the following raw materials in parts by weight: 32-37 parts of ethylene-vinyl acetate (EVA) resin, 68-72 parts of polycaprolactone (PCL), 2.8-3.2 parts of soybean meal, 2.7-3.6 parts of wood fibers, 1.2-1.7 parts of a titanate coupling agent NDZ-TTS, 3-3.6 parts of sodium lactate, 13-17 parts of a foaming agent ADC, 8-12 parts of zinc oxide, 9-10 parts of citric acid, 11-14 parts of sodium hydrogen carbonate, 1.6-1.9 parts of diisononyl phthalate (DINP), 2.2-2.7 parts of epoxy octyl stearate, 23-28 parts of barite powder, 15-18 parts of augite powder, 7-11 parts of white carbon black, 5-9 parts of mica powder, 3-6 parts of ammonium polyphosphate, 5-8 parts of melamine sodium polyphosphate, 1.5-1.8 parts of 2,6-di-tert-butyl-4-methylphenol (BHT) and 1.3-1.6 parts of an antioxidant BLE.

Owner:NINGGUO NINGSHENG RUBBER PROD

An environmentally friendly plastic material with slow decomposition rate and low water absorption

The invention discloses an environment-friendly plastic material with a low decomposition rate and a low water absorptivity. The environment-friendly plastic material is prepared from the raw materials in parts by weight: 20-25 parts of PCL (polycaprolactone), 65-70 parts of modified PHB (poly-beta hydroxybutyric acid), 13-18 parts of a peanut protein powder, 1.5-1.8 parts of jute fiber, 3-4 parts of wood fiber, 1.1-1.3 parts of a silane coupling agent A-151, 2-3 parts of sodium lactate, 1.1-1.6 parts of sodium diacetate, 2-2.2 parts of dioctyl phthalate DOP, 5-7 parts of epoxy tall butyl oleate, 2-4 parts of oxidized starch, 20-23 parts of nano white carbon black, 6-8 parts of light calcium carbonate, 3-5 parts of sea-foam stone powder, 5-9 parts of kaolin and 1-1.4 part of antioxidant. The environment-friendly plastic material can be degraded by natural microbes and has the advantages of low decomposition rate, oxidation resistance, good shock resistance and low water absorptivity.

Owner:中山佳晨实业有限公司

Compound reinforced iron-aluminum alloy aluminum-based material and production method and application thereof

ActiveCN112626378AHigh specific strengthImprove corrosion resistanceBraking discsRailway transportAluminum metalIntermetallic

The invention relates to a compound reinforced iron-aluminum alloy aluminum-based material and a production method and application thereof. The material comprises an aluminum-based alloy layer, a Fe3Al alloy layer which has metallurgical bonding with the aluminum-based alloy layer, and a FeAl alloy layer which has metallurgical bonding with the Fe3Al alloy layer, wherein the Fe3Al alloy layer is mainly composed of a Fe3Al phase and a ZrB2 phase, and the FeAl alloy layer is mainly composed of a FeAl phase, a B phase and an Al2O3 phase. Not only does the compound reinforced iron-aluminum alloy aluminum-based material have excellent high-temperature mechanical performance, corrosion resistance performance and wear resistance performance of iron-aluminum intermetallics, but also the advantages of high-thermal conductivity, light weights and the like of aluminum-based alloy are kept at the same time; and by using the material as a high-speed rail traffic brake disc material, on one hand, the production cost can be reduced greatly, on the other hand, a use temperature of brake discs can be significantly elevated, and the service lives of the brake discs can be significantly prolonged.

A protein plastic material

The invention discloses a protein plastic material comprising the following raw materials in parts by weight: 45-50 parts of PBS (poly butylenes succinate), 30-35 parts of poly-beta-hydroxybutyric acid (PHB), 20-25 parts of peanut protein powder, 2.5-3 parts of potassium titanate fiber, 5-7 parts of silk fiber, 1.2-1.7 parts of a silane coupling agent KH570, 2-3 parts of sodium sorbate, 1.1-1.6 parts of ethyl p-hydroxybenzoate, 1.7-1.9 parts of diisooctyl phthalate (DIOP), 3-6 parts of epoxidized soybean oil, 3-5 parts of starch acetate, 15-18 parts of talcum powder, 7-11 parts of wollastonite powder, 5-9 parts of calcite powder and 1-1.4 parts of tert-butylhydroquinone (TBHQ). The protein plastic material disclosed by the invention can be decomposed by microorganisms, and is strong in ductility and good in impact resistance and oxidation resistance, the generation of white pollution can be avoided and the consumption of agricultural product resources can also be reduced.

Owner:威海正森新材料科技有限公司

Electric power metering box for photovoltaic power generation

The invention belongs to the field of electric power materials, and discloses an electric power metering box for photovoltaic power generation. The electric power metering box comprises a box body, wherein the box body is prepared from the following raw materials: chlorinated butyl rubber, ethylene propylene terpolymer, methyl vinyl silicone rubber, polycarbonate, glass fiber, silicon carbide, aluminum oxide, molybdenum disulfide, graphite, N-methyl pyrrolidone, kieselguhr, kaoline, an anti-aging agent 2246 and a hindered phenol antioxidant. Through improvement on a plastic material, the comprehensive performance of the electric power metering box for photovoltaic power generation is improved, and the application range is wide.

Owner:李光明

A degradable plastic material

The invention discloses a degradable plastic material. The degradable plastic material comprises the following raw materials in part by weight: 5-50 parts of hydroxybutyrate and valeric acid copolyester PHBV4, 50-55 parts of peanut protein prowder, 15-18 parts of nanometer cellulose whiskers, 12-15 parts of coconut fibers, 3-5 parts of amylase, 1.5-2.2 parts of silane coupling agents, 2-3 parts of potassium sorbate, 2-3 parts of dehydroacetic acids, 1.4-1.6 parts of dioctyl phthalate, 1.2-1.6 parts of zinc stearate, 10-12 parts of hard clay, 5-9 parts of kaolin, 7-11 parts of sepiolite and 1-1.4 parts of 2, 6- di-tert-butyl-4-methylphenol BHT. The degradable plastic material can be completely decomposed into micromolecule substances under effects of microorganisms; the tensile strength, the breakage elongation and the light transmission of the degradable plastic material are close to those of the existing polypropylene; and the degradable plastic material can replace the polypropylene in some fields.

Owner:浙江创新旭隆新材料科技有限公司

A flame-retardant and aging-resistant rubber material

The invention discloses an anti-flaming aging-resistant rubber material which comprises the following constituents in parts by weight: 40 parts to 45 parts of butadiene styrene rubber, 30 parts to 36 parts of polyurethane elastomer, 10 parts to 15 parts of chlorinated butyl rubber, 2 parts to 3 parts of vulcanizing agent BPO, 1.2 parts to 1.8 parts of sulphur, 2 parts to 4 parts of divinyl carboxylic acid sodium, 20 parts to 30 parts of calcite powder, 9 parts to 11 parts of kieselguhr, 5 parts to 7 parts of aluminum silicate, 14 parts to 15 parts of carbon black N660, 14 parts to 15 parts of carbon black N330, 10 parts to 12 parts of magnesium hydroxide, 3 parts to 5 parts of quartz powder, 5 parts to 7 parts of zinc oxide, 2 parts to 4 parts of calcium stearate, 5 parts to 8 parts of barium stearate, 5 parts to 7 parts of diphenyl phosphate ester, 2 parts to 4 parts of melamine, and 1.5 parts to 2.5 parts of silane coupling agent KH450. The anti-flaming aging-resistant rubber material has an excellent anti-flaming aging-resistant performance, so that smog is effectively prevented from generating during a combustion process; besides, the ozone resistance and the weather resistance of the anti-flaming aging-resistant rubber material are excellent; moreover, the anti-flaming aging-resistant rubber material further has the advantages of high elasticity, high hardness and high strength.

Owner:南通鹏达体育用品有限公司

A kind of environment-friendly polycaprolactone plastic material

ActiveCN104312115BGood flexibilityReasonable control of the amount addedPolyvinyl alcoholAntioxidant

The invention discloses an environment-friendly polycaprolactone plastic material which is prepared from the following raw materials in parts by weight: 8-12 parts of starch, 15-20 parts of polyvinyl alcohol solution, 0.8-1.3 parts of glyoxal water solution, 5-10 parts of tung oil, 30-40 parts of polycaprolactone, 8-12 parts of potassium titanate, 1.5-2 parts of gamma-(methylacryloyloxy)propyltrimethoxy silane, 1.5-2 parts of ethyl p-hydroxybenzoate, 1.8-2.2 parts of diisononyl phthalate, 1-1.5 parts of urea, 5-8 parts of butyl epoxy tall oil ester, 5-7 parts of jute fiber, 6-7 parts of oxidized starch, 22-24 parts of meerschaum powder, 1.5-2.2 parts of tert-butyl hydroquinone, 15-18 parts of ethylene glycol, 12-16 parts of water, 1.5-2.2 parts of sodium lactate, 1.4-1.5 parts of sodium diacetate and 1.5-2 parts of antioxidant 1010. The environment-friendly polycaprolactone plastic material has the advantages of favorable biodegradability, environment friendliness, excellent aging resistance, excellent water resistance and favorable mechanical properties.

Owner:广东中凯塑业有限公司

A kind of environment-friendly poly-β-hydroxybutyric acid plastic material

ActiveCN104231581BReasonable control of the amount addedImprove mechanical propertiesEthyl hydroxybenzoateSilanes

The invention discloses an environment-friendly poly-beta-hydroxybutyric acid plastic material. The environment-friendly poly-beta-hydroxybutyric acid plastic material is composed of raw materials including, by weight part, 15-20 parts of corn starch, 8-12 parts of 5-7% polyvinyl alcohol solution, 0.5-0.8 part of 25-35% crosslinking agent and glycol water solution, 8-12 parts of cashew phenolic resin, 25-30 parts of poly-beta-hydroxybutyric acid, 5-8 parts of potassium titanate fiber, 2-3 parts of gamma-(methylacryloyl oxygen) methyl propyl trimethoxy silane, 2-2.5 parts of ethyl p-hydroxybenzoate, 1.5-2 parts of di-2-ethylhexyl phthalate, 0.5-0.8 part of urea, 5-8 parts of epoxidized soybean oil, 4-8 parts of silk fiber, 5-8 parts of starch acetate, 20-25 parts of talcum powder, 15-20 parts of calcite powder, 2-2.5 parts of tert-butylhydroquinone, 20-25 parts of glycerol and 15-18 parts of distilled water. The environment-friendly poly-beta-hydroxybutyric acid plastic material is environmentally friendly, high in biodegradation performance and waterproof performance and excellent in ageing-resistant performance and mechanical performance.

Owner:GUANGDONG KAIYU SCI & EDUCATION CULTURE CO LTD

A flame-retardant heat-resistant rubber material

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

Closed low-voltage distribution box

The invention belongs to the field of distribution equipment, and discloses a closed low-voltage distribution box. The closed low-voltage distribution box comprises a box body which is prepared according to the following process: step 1) preparation of a component A; step 2) preparation of a component B; step 3) preparation of a component C; and step 4) preparation of the box body. The distribution box provided by the invention has the advantages of large mechanical strength, corrosion resistance and good flame retardant performance.

Owner:化晨冰

Iron-aluminum composite reinforced aluminum-based material, its preparation method and application

ActiveCN112626378BHigh specific strengthImprove corrosion resistanceBraking discsMetallic material coating processesAlloy compositeAluminum metal

Owner:HUNAN JINTIAN ALUMINUM HI TECH CO LTD

A highly ductile, impact-resistant, oxidation-resistant modified environmentally friendly plastic

The invention discloses a modified environment-friendly plastic with high ductility, impact resistance and oxidation resistance. The raw materials include 45-50 parts of polybutylene succinate PBS and 30-35 parts of poly-β-hydroxybutyrate PHB in parts by weight. 20-25 parts of peanut protein powder, 2.5-3 parts of potassium titanate fiber, 12-15 parts of coconut fiber, 1.2-1.7 parts of silane coupling agent KH570, 2-3 parts of sodium sorbate, ethyl p-hydroxybenzoate 1.1-1.6 parts, 1.4-1.6 parts of dioctyl phthalate DOP, 1.2-1.6 parts of zinc stearate, 3-5 parts of acetate starch, 15-18 parts of talcum powder, 7-11 parts of wollastonite powder, Calcite powder 5-9 parts, sepiolite 7-11 parts, tert-butyl hydroquinone TBHQ 1-1.4 parts, 2,6-di-tert-butyl-4-methylphenol BHT 1-1.4 parts. The invention can be decomposed by microorganisms, has strong ductility, good impact resistance and oxidation resistance.

Owner:珠海市安迪尔生物科技有限公司

Low-voltage comprehensive integrated cabinet

The invention belongs to the field of electrical equipment and discloses a low-voltage comprehensive integrated cabinet. The low-voltage comprehensive integrated cabinet comprises a cabinet body whichis prepared from the following raw materials: palygorskite, aluminum nitride, triphenyl phosphate, antimony oxide, diatomite, kaolin, molybdenum disulfide, graphite, N-methylpyrrolidone, wood meal, bisphenol-A type epoxy resin, phenolic resin, polyvinyl alcohol, glass fiber, white oil, talcum powder and carbon fiber. The low-voltage comprehensive integrated cabinet provided by the invention has the advantages of good insulation performance, thermal conductivity and flame retardant property, large mechanical properties, and capability of replacing metal products in the market.

Owner:苏永义

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com