Degradable plastic material

A technology for degrading plastics and raw materials, which is applied in the field of plastic materials, can solve the problems of high recycling production costs, and achieve excellent bending fatigue resistance, improved compatibility, and low relative density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

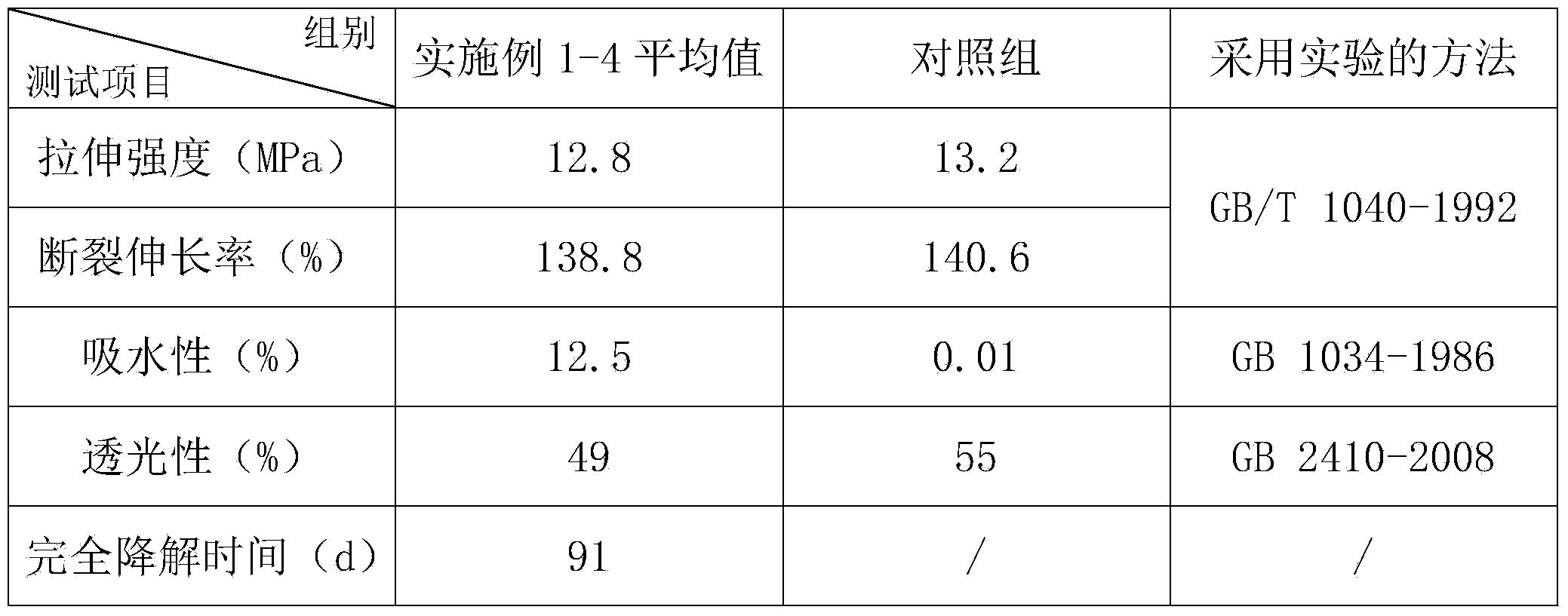

Examples

Embodiment 1

[0013] A kind of degradable plastic material that the present invention proposes, its raw material comprises by weight: 45 parts of hydroxybutyrate valeric acid copolyester PHBV, 55 parts of peanut protein powders, 15 parts of nano-cellulose whiskers, 15 parts of coconut fibers, linear 3 parts of starch, 2.2 parts of silane coupling agent KH560, 2 parts of potassium sorbate, 3 parts of dehydroacetic acid, 1.4 parts of dioctyl phthalate DOP, 1.6 parts of zinc stearate, 10 parts of hard clay, 9 parts of kaolin, 7 parts of sepiolite, 1.4 parts of 2,6-di-tert-butyl-4-methylphenol BHT, wherein the protein content of peanut protein powder is 70wt%;

[0014] During the preparation process, the silane coupling agent KH560 was added to the nanocellulose whiskers and stirred at a stirring speed of 28rpm for 7min, then coconut fiber and amylose were added and stirred at a stirring speed of 30rpm for 8min, and then peanut protein powder was added to stir at a stirring speed of 38rpm Stir ...

Embodiment 2

[0016] A kind of degradable plastic material that the present invention proposes, its raw material comprises by weight: 49 parts of hydroxybutyrate valeric acid copolyester PHBV, 51 parts of peanut protein powders, 17 parts of nano-cellulose whiskers, 13 parts of coconut fiber, linear 4.5 parts of starch, 1.7 parts of silane coupling agent KH560, 2.6 parts of potassium sorbate, 2.1 parts of dehydroacetic acid, 1.56 parts of dioctyl phthalate DOP, 1.3 parts of zinc stearate, 11.2 parts of hard clay, 6 parts of kaolin, 10 parts of sepiolite, 1.1 parts of 2,6-di-tert-butyl-4-methylphenol BHT, wherein the protein content of peanut protein powder is 76wt%;

[0017] During the preparation process, the silane coupling agent KH560 was added to the nanocellulose whiskers and stirred at a stirring speed of 20rpm for 10min, then coconut fiber and amylose were added and stirred at a stirring speed of 23rpm for 12min, and then peanut protein powder was added at a stirring speed of 35rpm St...

Embodiment 3

[0019] A kind of degradable plastic material that the present invention proposes, its raw material comprises by weight: 47 parts of hydroxybutyrate valeric acid copolyester PHBV, 53 parts of peanut protein powders, 16 parts of nano-cellulose whiskers, 14 parts of coconut fibers, linear 3.5 parts of starch, 2.1 parts of silane coupling agent KH560, 2.2 parts of potassium sorbate, 2.4 parts of dehydroacetic acid, 1.43 parts of dioctyl phthalate DOP, 1.5 parts of zinc stearate, 10.6 parts of hard clay, 8 parts of kaolin, 8 parts of sepiolite, 1.3 parts of 2,6-di-tert-butyl-4-methylphenol BHT, wherein the protein content of peanut protein powder is 74wt%;

[0020] During the preparation process, the silane coupling agent KH560 was added to the nanocellulose whiskers and stirred at a stirring speed of 23rpm for 9min, then coconut fiber and amylose were added and stirred at a stirring speed of 28rpm for 10min, and then peanut protein powder was added to stir at a stirring speed of 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com