Low-voltage comprehensive integrated cabinet

A low-voltage, cabinet technology, applied in the field of low-voltage integrated cabinets, can solve the problems of poor mechanical performance, corrosion resistance, poor thermal conductivity, poor insulation performance, inconvenient installation, etc., to improve mechanical performance and corrosion resistance, Improves dispersion effect and prevents material disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A low-voltage comprehensive integrated cabinet, which includes a cabinet body, and the cabinet body is prepared from the following raw materials:

[0017] Palygorskite, aluminum nitride, triphenyl phosphate, antimony oxide, diatomaceous earth, kaolin, molybdenum disulfide, graphite, N-methylpyrrolidone, wood powder, bisphenol A epoxy resin, phenolic resin, polyethylene Alcohol, glass fiber, white oil, talc, carbon fiber.

[0018] The cabinet is prepared according to the following process:

[0019] Add palygorskite to the crusher in order to crush, pass through a 200-mesh sieve, and then mix it with aluminum nitride, triphenyl phosphate, and antimony oxide according to the mass ratio of 3:2:2:1 to obtain auxiliary material A;

[0020] Mix diatomaceous earth and kaolin according to the mass ratio of 1:1, then calcinate at 800°C for 10 minutes, then take it out and pulverize it to obtain auxiliary material B;

[0021] Molybdenum disulfide and graphite were mixed accordin...

Embodiment 2

[0024] A low-voltage comprehensive integrated cabinet, which includes a cabinet body, and the cabinet body is prepared from the following raw materials:

[0025] Palygorskite, aluminum nitride, triphenyl phosphate, antimony oxide, diatomaceous earth, kaolin, molybdenum disulfide, graphite, N-methylpyrrolidone, wood powder, bisphenol A epoxy resin, phenolic resin, polyethylene Alcohol, glass fiber, white oil, talc, carbon fiber.

[0026] The cabinet is prepared according to the following process:

[0027] Add palygorskite to the crusher in order to crush, pass through a 200-mesh sieve, and then mix it with aluminum nitride, triphenyl phosphate, and antimony oxide according to the mass ratio of 3:2:2:1 to obtain auxiliary material A;

[0028] Mix diatomaceous earth and kaolin according to the mass ratio of 1:1, then calcinate at 800°C for 10 minutes, then take it out and pulverize it to obtain auxiliary material B;

[0029] Molybdenum disulfide and graphite were mixed accordin...

Embodiment 3

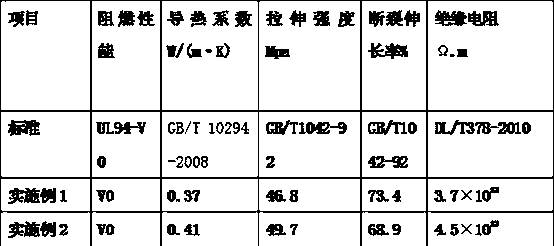

[0032] Cabinet material performance test of the present invention:

[0033] 1. The cabinet body material prepared in embodiment 1-2 is made standard test piece according to test standard, carries out following performance test, and the results are shown in Table 1:

[0034] Table 1

[0035]

[0036] 2. Corrosion resistance: soak the cabinet material in 10% dilute hydrochloric acid solution or 8% sodium hydroxide solution or 6% sodium chloride solution for 480 hours, there is no obvious change in the appearance and performance parameters of the test, prompting The material has good corrosion resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com