A dcc cracking naphtha processing technology

A processing technology and naphtha technology, which is applied in the petroleum industry, hydroprocessing technology, hydrocarbon oil treatment, etc., can solve the problems of low sales price and affecting the economic benefits of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

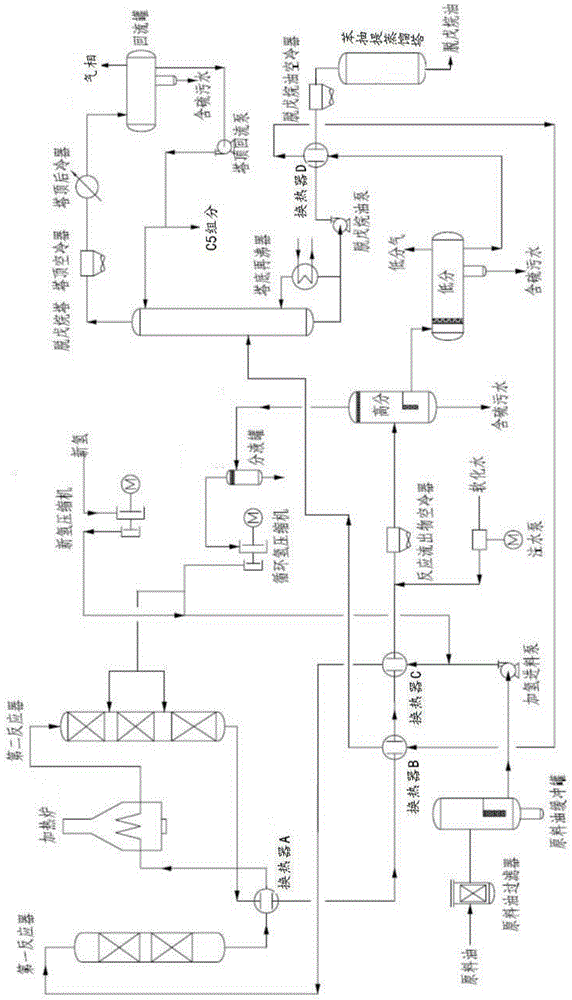

[0027] The present embodiment provides a kind of DCC cracking naphtha processing technology, such as figure 1 shown, including the following steps:

[0028] Step 1: The DCC cracked naphtha from the tank area is filtered through a raw material oil filter to remove particles with a particle size greater than 25 μm in the raw material and enter the raw material oil buffer tank. The raw material oil coming out of the raw material buffer tank bottom is added The hydrogen reaction feed pump boosts the pressure to 7.0-7.9MPa.

[0029] Step 2: The new hydrogen from the pipeline network is pressurized to 7.0-7.9MPa by the new hydrogen compressor, and then mixed with the boosted raw material oil obtained in step 1 to obtain a hydrogen-mixed raw material oil, in which new hydrogen and raw material The mixing ratio of oil is: 1 ton of raw material oil mixed with 1.14 tons of hydrogen. The hydrogen-mixed raw oil passes through the heat exchanger C to exchange heat to 170-200°C, and then ...

Embodiment 2

[0043] The following will be described in conjunction with specific implementation data.

[0044] Firstly, the DCC cracked naphtha from the tank area is filtered through a raw oil filter to remove particles with a particle size larger than 25 μm in the raw material and then enters the raw material oil buffer tank, and the raw material oil from the bottom of the raw material buffer tank is hydrogenated The reaction feed pump boosts the pressure to 7.5MPa; on the other hand, the new hydrogen from the pipeline network is pressurized to 7.5MPa by the new hydrogen compressor, and then mixed with the boosted raw material oil obtained above to obtain a mixed hydrogen For raw oil, adjust the pump speed so that the mixing ratio of new hydrogen and raw oil satisfies: 0.0141 tons of hydrogen for 1 ton of raw oil. The hydrogen-mixed raw oil passes through the heat exchanger C to exchange heat to 185°C, and then enters the first hydrogenation reactor.

[0045] In the first hydrogenation r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com