A kind of camphor tree seed flavoring for tobacco and preparation method thereof

A technology for tobacco flavor and camphor seeds, which is applied in the field of camphor seed tobacco flavor and its preparation, can solve the problems of weak and full aroma, insufficient smoke concentration, poor comfort, etc., and achieves elegant aroma, improved smoke quality, and improved production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

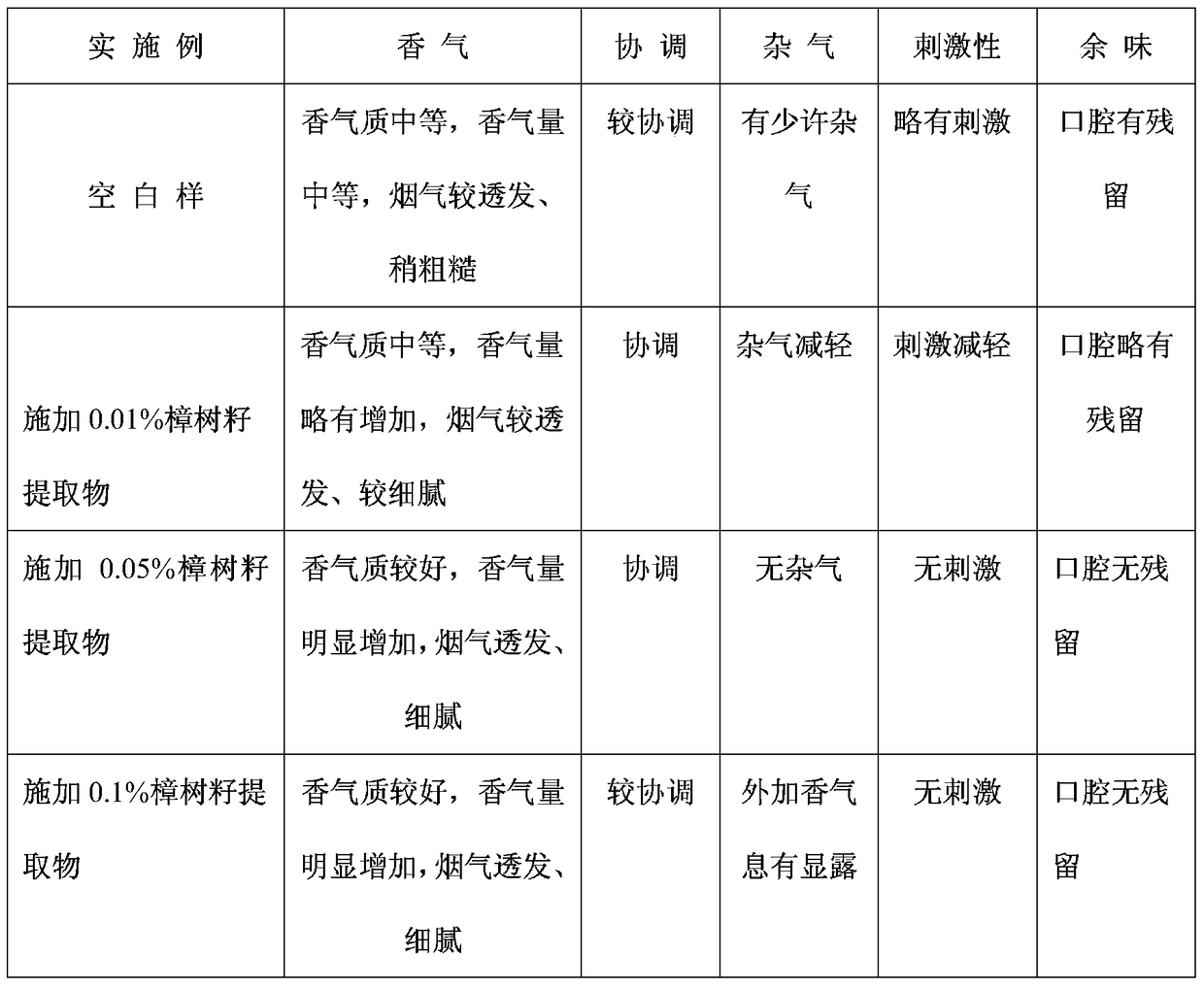

Examples

preparation example Construction

[0024] The preparation method of described camphor tree seed flavoring for tobacco comprises the steps:

[0025] A. Wash the camphor seeds, filter and dry them, and soak them in 60% to 95% edible ethanol solution for 5 to 7 days;

[0026] B. Squeeze the dissolved juice, and extract the filtrate by suction;

[0027] C. the filtrate obtained in step B is distilled by steam, the vapor pressure is 665.5~1333Pa, and the distillation speed is 0.5~1 drop / S with the distillate flow rate;

[0028] D. The extract obtained in step C is mixed with edible ethanol, which is the spice for tobacco of the camphor tree seeds.

[0029] The quality of the 60%-95% edible ethanol is 2 to 10 times that of the camphor tree seeds.

[0030] The chemical composition of the extract in the step C was analyzed by gas chromatography-mass spectrometry, 23 peaks were separated, 19 compounds were identified, and the density was 0.890-0.906g / cm 3 .

[0031] The specific key chemical components are shown in ...

Embodiment 1

[0036] 100 parts by weight of camphor tree seeds were washed and dried, and naturally soaked in 400 parts by weight of 70% edible ethanol solution for 7 days; the juice was squeezed, filtered out and clarified with qualitative filter paper, and the extract was obtained; the filtrate was steam distilled, At 100°C, its vapor pressure is 665.5-1333Pa, so that the filtrate is distilled out with water vapor at a distillation rate of 0.5 drops / S at a temperature lower than 100°C. When the effluent is clear and transparent, it no longer contains oil droplets of organic substances. When the water vapor distillation is over, it can be concluded that the steam distillation is over, and finally a colorless or slightly yellow, fresh and slightly nasal, with a camphor breath extract is obtained; the alcohol is separated by steam distillation to obtain a uniform, stable, sweet liquid flavor additive, and the Impurities, the relative content of key aroma components that constitute its aroma c...

Embodiment 2

[0038] Wash and dry 100 parts by weight of camphor tree seeds, soak them in 800 parts by weight of 80% edible ethanol solution naturally for 6 days; squeeze the dissolved juice, filter out and clarify with qualitative filter paper, and obtain the extract; the filtrate is steam distilled, At 100°C, its vapor pressure is 665.5-1333Pa, so that the filtrate is distilled out with water vapor at a distillation rate of 0.5 drops / S at a temperature lower than 100°C. When the effluent is clear and transparent, it no longer contains oil droplets of organic substances. When the water vapor distillation is over, it can be concluded that the steam distillation is over, and finally a colorless or slightly yellow, fresh and slightly nasal, with a camphor breath extract is obtained; the alcohol is separated by distillation to obtain a uniform, stable, sweet liquid flavor additive, and impurities are removed. The relative content of key aroma components constituting its aroma characteristics is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com