Production method for bacillus licheniformis with high sporation rate

A technology of Bacillus licheniformis and production methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of prolonging the fermentation time, increasing production costs, and limiting the amount of manganese, so as to improve the sporulation rate, The effect of good product quality and reduced fermentation production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

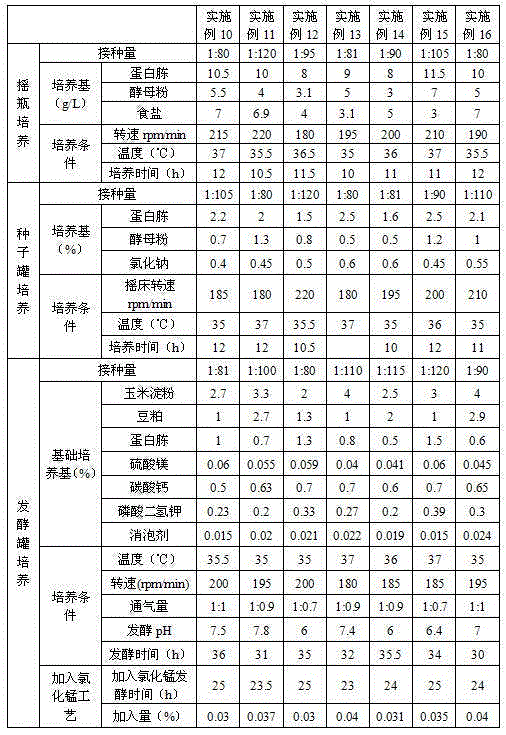

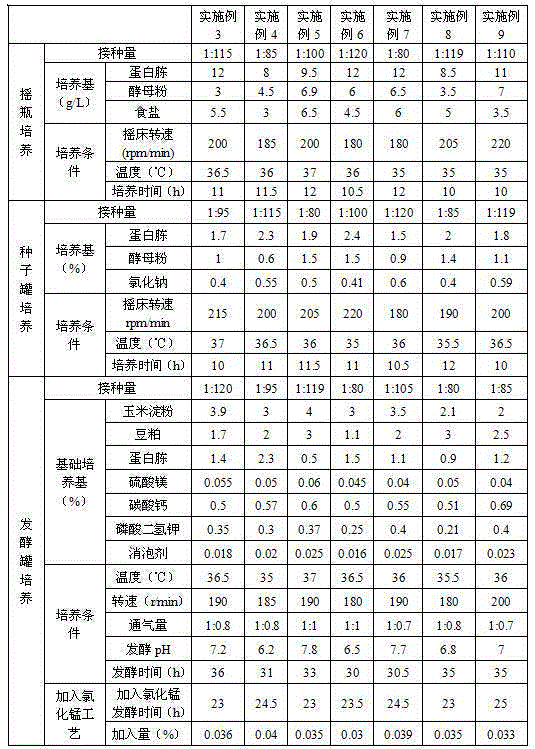

[0020] The production method of a hyperbophabal ground, including the following steps:

[0021] 1) Cultivation of bottle of bottle: Inocularly inocus to the bottle medium, the vaccination amount is 1: (80 ~ 120) to the bed in the bed;37 ° C, the cultivation time is 10 ~ 12 hours; the protein is 8 ~ 12g per liter bottle medium, 3 ~ 7g of yeast powder, 3 ~ 7g of salt, the rest is water; the rest are water; the rest are water;

[0022] 2) Seed tank culture: Putting steps 1) The obtained device Bacillus liquid is inoculated to the seed medium, the vaccination amount is trained at a volume ratio of 1: (80 ~ 120), the speed is 180 ~ 220rpm / min, the temperature is 35 ~ 35 ~37 ° C, the cultivation time is 10 ~ 12 hours; the seed medium formula is: protein 胨 1.5 ~ 2.5%, yeast powder 0.5 ~ 1.5%, sodium chloride 0.4 ~ 0.6%.

[0023] 3) Cultivation of fermentation tanks: Step 2) The obtained Lidobacteria bacteria liquid is inoculated to the fermentation foundation medium, and the amount of va...

Embodiment 2

[0026] The production method of a hyperbophabal ground, including the following steps:

[0027] 1) Shake bottle culture: Pretend to 1L medium according to the formula, the average packaging and 10 1000ml triangle bottle, after high temperature sterilization and cooling, use the ground to vaccinate with the ground, the amount of inoculation is 100, the bed is cultivated, the speed is 220rpm / min, the speed is 220rpm / min.The temperature is 37 ° C, the cultivation time is 11 hours;

[0028] Cultivation base formula: 10g of protein 胨; 3 to 7g of yeast powder; 3 to 7g of salt, setting it with distilled water to 1L, high -pressure steam 121 ℃ sterilized;

[0029] 2) Seed tank culture: Curma formula: 2%protein 胨, 1%yeast powder, 0.5%sodium chloride. Drinking water preparation, 300 liters of volume, high -pressure steam 121 ℃ sterilized for 30 minutes, vaccination volume 1: 100, speed is the speed of speed, the speed is to the speed, the speed is to the speed, the speed is to the speed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com