Quasicrystal phase reinforced LPSO structured Mg-Zn-Y magnesium alloy and preparation method thereof

A technology of magnesium alloy and quasicrystal phase, which is applied in the field of LPSO structure Mg-Zn-Y magnesium alloy enhanced by quasicrystal phase and its preparation, can solve the problem that the strength is difficult to meet the mechanical performance requirements of bearing parts, and achieve high temperature creep resistance. High and good creep resistance, the effect of improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

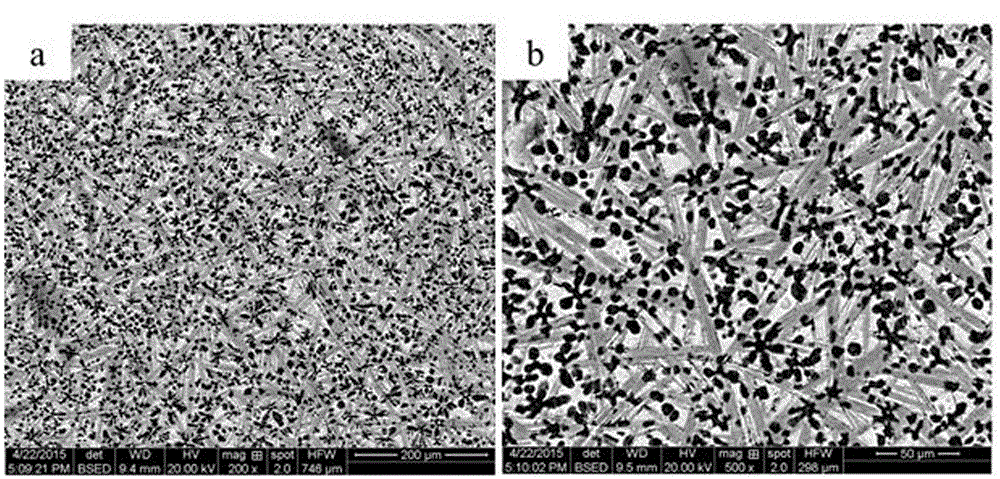

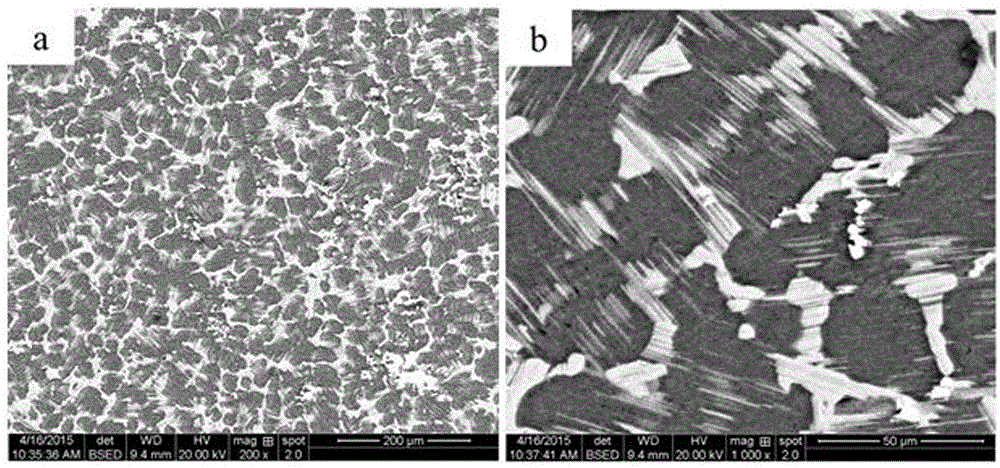

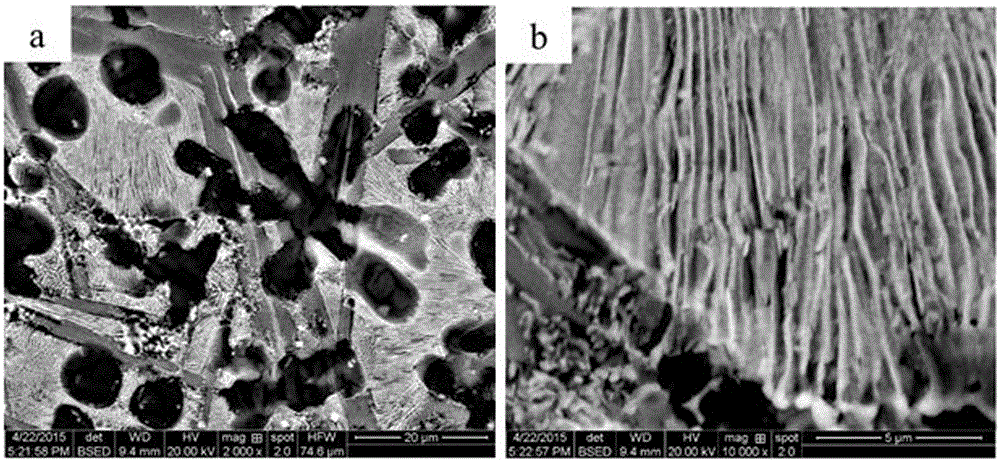

Embodiment 1

[0036] A Mg-Zn-Y magnesium alloy with a quasicrystalline phase reinforced LPSO structure is composed of the following components in mass percentage: Zn5.51%, Y13.35%, and the balance is Mg.

[0037] Take the following steps to make:

[0038] 1) Preparation of Mg-Y master alloy by conventional casting method:

[0039] Using the weight ratio of 29.50%Y and 70.50%Mg as the raw material, put it into the crucible to heat and melt it and raise the temperature to 830°C. After stirring evenly, pour the metal mold to obtain the Mg-Y master alloy. SF is introduced during the melting process. 6 -CO 2 Mixed gas protection to get Mg-Y master alloy;

[0040] 2) Preparation of Mg-Zn-Y quasicrystal master alloy:

[0041] Weigh pure zinc ingots, Mg-Y master alloy and pure magnesium ingot raw materials prepared in step 1) according to the ratio, and the weight percentage composition is: 55.00% pure zinc ingots, 20.34% Mg-Y master alloys, and the balance is pure magnesium Spin, in SF 6 -CO ...

Embodiment 2

[0048] A Mg-Zn-Y magnesium alloy with a quasicrystalline phase reinforced LPSO structure is composed of the following components in mass percentage: Zn7.02%, Y13.00%, and the balance is Mg.

[0049] Take the following steps to make:

[0050] 1) Preparation of Mg-Y master alloy by conventional casting method:

[0051] Use the weight ratio of 30.00%Y and 70.00%Mg as the raw material, put it into the crucible, heat and melt it and raise the temperature to 805°C, stir it evenly and pour the metal mold to make the Mg-Y master alloy, and add SF during the melting process 6 -CO 2 Mixed gas protection to get Mg-Y master alloy;

[0052] 2) Preparation of Mg-Zn-Y quasicrystal master alloy:

[0053] Weigh pure zinc ingots, Mg-Y master alloy and pure magnesium ingot raw materials prepared in step 1) according to the ratio, and the weight percentage composition is: 55.50% pure zinc ingot, 18.33% Mg-Y master alloy, and the balance is pure magnesium Spin, in SF 6 -CO 2 Under the protec...

Embodiment 3

[0060] A Mg-Zn-Y magnesium alloy with a quasicrystalline phase reinforced LPSO structure is composed of the following components in mass percentage: Zn8.96%, Y12.11%, and the balance is Mg.

[0061] Take the following steps to make:

[0062] 1) Preparation of Mg-Y master alloy by conventional casting method:

[0063] Using the weight ratio of 29.80%Y and 70.20%Mg as the raw material, put it into the crucible, heat and melt it and raise the temperature to 810°C, stir it evenly and pour the metal mold to make the Mg-Y master alloy, and add SF during the melting process 6 -CO 2 Mixed gas protection to get Mg-Y master alloy;

[0064] 2) Preparation of Mg-Zn-Y quasicrystal master alloy:

[0065] Weigh pure zinc ingots, Mg-Y master alloy and pure magnesium ingot raw materials prepared in step 1) according to the proportion, and the weight percentage composition is: 55.60% pure zinc ingot, 17.79% Mg-Y master alloy, and the balance is pure magnesium Spin, in SF 6 -CO 2 Under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain diameter | aaaaa | aaaaa |

| Average grain diameter | aaaaa | aaaaa |

| Average grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com