Formless construction technology of an environment-friendly high-strength micro-expansion grouting material

A technology of construction technology and grouting material, which is applied in the direction of foundation structure engineering, on-site coagulation pavement, wellbore lining, etc., which can solve the difficulty in quality control of hidden projects of pre-embedded components, the construction of grouting material is not allowed, and the construction difficulty is increased and other issues, to achieve the effect of maximizing the effect of enterprises and society, shortening the construction period and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0041] 1) The main performance index of environment-friendly high-strength micro-expansion grouting material adopts compressive strength: 45MPa;

[0042] 2) Control the ratio of water to material: 0.25:1;

[0043] 3) The mixing water shall be in accordance with the "Concrete Mixing Water Standard" (JGJ63), the water temperature: 40°C, and the mortar mixer shall be used for mixing;

[0044] 4) Stirring and feeding sequence and stirring time: first add grouting material and reinforcing material and stir for 1 minute, then add water and stir, the total stirring time is 3 minutes;

[0045] 5) Before pouring, the surface of the reinforced base should be chiseled and cleaned, and no debris such as gravel, laitance, dust, oil, and release agent should be left; 24 hours before pouring, the surface of the base should be fully wet, and 1 hour before grouting, absorb water;

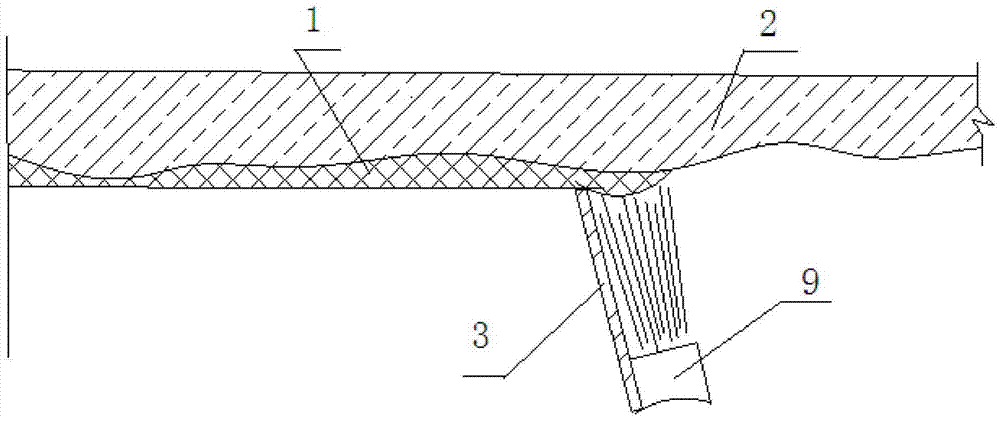

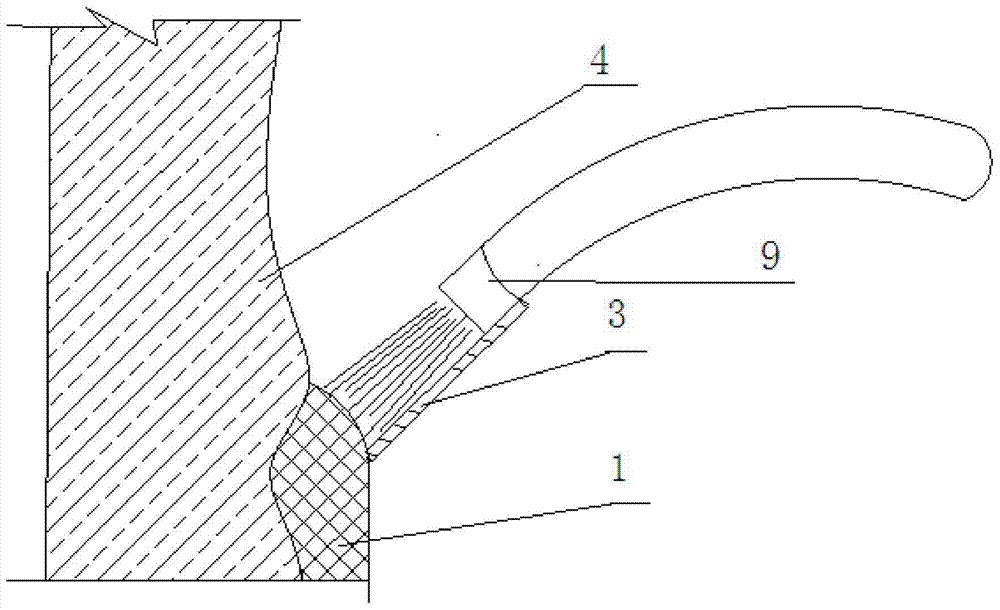

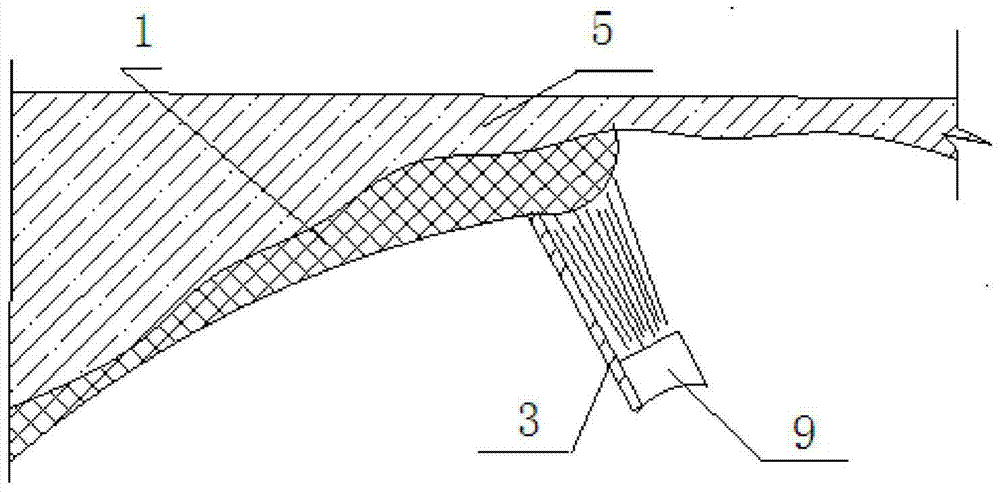

[0046] 6) Set the cloth scraper 3 on the upper end of the metal pouring pipe 9, the metal pipe is 5mm higher th...

example 2

[0050] 1) The main performance index of environment-friendly high-strength micro-expansion grouting material adopts compressive strength: 50MPa;

[0051] 2) Control the ratio of water to material: 0.23:1;

[0052] 3) The water for mixing shall comply with the "Standard for Water for Concrete Mixing" (JGJ63).

[0053]4) Stirring and feeding sequence and stirring time: first add grouting material and reinforcing material and stir for 1 minute, then add water and stir, the total stirring time is 3.5 minutes;

[0054] 5) Before pouring, the surface of the reinforced base should be chiseled, cleaned, and no debris should be left; 24 hours before pouring, the surface of the base should be fully wet, and 1 hour before grouting, the accumulated water should be absorbed;

[0055] 6) Set the cloth scraper 3 on the upper end of the metal pouring pipe 9, the metal pipe is 5mm higher than the upper plane of the clamp 8, and at the same time use bolts and nuts to fix the clamp and the meta...

example 3

[0059] 1) The main performance index of environment-friendly high-strength micro-expansion grouting material adopts compressive strength: 55MPa;

[0060] 2) Control the ratio of water to material: 0.21:1;

[0061] 3) The mixing water shall be in accordance with the "Concrete Mixing Water Standard" (JGJ63), the water temperature: 20°C, and the mortar mixer shall be used for mixing;

[0062] 4) Stirring and feeding sequence and stirring time: first add grouting material and reinforcing material and stir for 1min, then add water and stir, the total stirring time is 4.0min;

[0063] 5) Before pouring, the surface of the reinforced base should be chiseled, cleaned, and no debris should be left; 24 hours before pouring, the surface of the base should be fully wet, and 1 hour before grouting, the accumulated water should be absorbed;

[0064] 6) Set the cloth scraper 3 on the upper end of the metal pouring pipe 9, the metal pipe is 8mm higher than the upper plane of the clamp 8, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com