Novel positive temperature coefficient (PTC) heating plastic tube and fabrication method thereof

A plastic pipe and a new technology, applied in the field of new PTC heating plastic pipe and its preparation, can solve the problems of limiting the application range of pipe parts, large size of pipe parts, difficulty in coiling pipe parts, etc., and achieve the change of pipe diameter and overall quality The effect of light weight and pipe size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

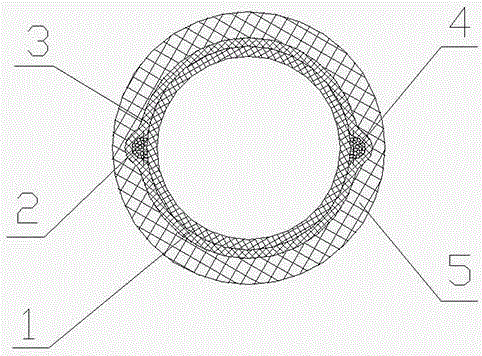

[0032] A new type of PTC heating plastic tube, including a heating tube and an outer sheath 5, the polytetrafluoroethylene outer sheath covers the outside of the tube body, the heating tube includes a plastic tube 1, a PTC heating material 3 and an electrode conductor, the plastic tube The outside is covered with two strands of spiral electrode conductors with an angle of 180° and arranged in parallel. The electrode conductors include electrode conductor A2 and electrode conductor B4. The electrode conductor is wrapped with PTC heating material, and the electrode conductor is wound by multiple strands of copper core wire. made. The preparation process includes a. preparation of electrode conductors; b. preparation of PTC heating material for the PTC layer, c. the percentages of the components of the PTC heating material are: polyethylene polymer 35%, 5μm carbon black 47%, acrylonitrile 5%, Nano-montmorillonite 10%, processing aid 3%, put each component into a torque rheometer,...

Embodiment 2

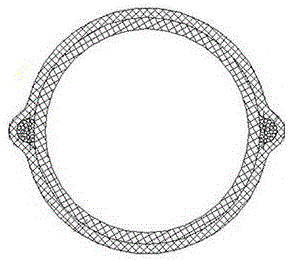

[0034] A new type of PTC heating plastic tube, including a heating tube and an outer sheath, the polytetrafluoroethylene outer sheath covers the outside of the tube body, the heating tube body includes a plastic tube, PTC heating material and electrode conductors, and the outer coating of the plastic tube There are two spiral electrode conductors with an included angle of 180° and arranged in parallel. The electrode conductors include electrode conductor A and electrode conductor B. The electrode conductor is wrapped with PTC heating material, and the electrode conductor is wound by multiple strands of copper core wire. The preparation process includes a. preparation of electrode conductors; b. preparation of PTC heating material, c. The percentage of each component of PTC heating material is: polypropylene polymer 28%, 7μm carbon black 50%, amide 6%, nano-montmorillonite 15%, processing aid 1%, put each component into a torque rheometer, internal mixer, open mill, single-screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com