Atmosphere controlled ice-temperature fresh-keeping method for food

A fresh-keeping method and air-conditioning technology, which is applied in food preservation, food science, application, etc., can solve problems such as short shelf life, food aging and denaturation, freezing damage, etc., and achieve the effects of reducing microbial growth, slow growth speed, and less nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

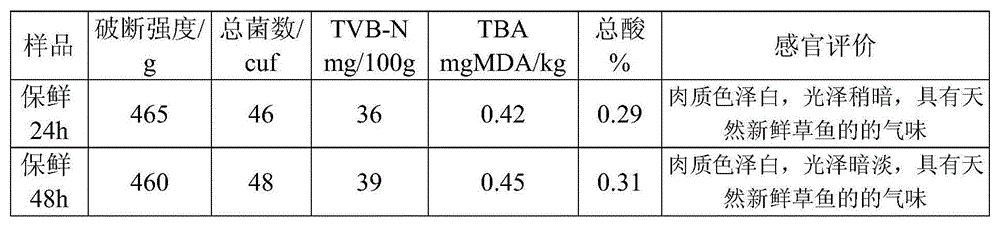

Examples

Embodiment 1

[0027] Choose kiwi fruit as raw material, follow the steps below:

[0028] ① Raw material removal of impurities: Take 1kg of fresh kiwifruit, use the drainage method to obtain a volume of kiwifruit of 1.12L, remove impurities, and use at least 1kg of tap water to wash the removed kiwifruit 4 times;

[0029] ② Disinfection water spray: Use 8 mg / L ozone water to spray the cleaned kiwi fruit for 5 minutes, and the volume of ozone water used is 6 times the volume of kiwi fruit, and the water on the surface of kiwi fruit is drained;

[0030] ③ Surface drying: At 5°C and 20 L / min of flowing air, process the kiwi fruit obtained in step ② for 5 minutes, and the flowing air is filtered with 200-mesh filter cloth;

[0031] ④ Bagging and air conditioning: pack the sterilized kiwi fruit in step ③ into bags, vacuumize and seal, so that the pressure inside the bag is 0.08Mpa;

[0032] ⑤ Cooling: Cool the bagged kiwi fruit at -3°C for 20 minutes;

[0033] ⑥Insulation and heat preservation:...

Embodiment 2

[0035] Choose lotus root as raw material, follow the steps below:

[0036] ①Removing impurities from raw materials: Take 5kg of fresh lotus root, use the hammer sinking method to obtain a lotus root volume of 5.8L, remove impurities, and wash with at least 5kg of tap water for 3 times;

[0037] ② Disinfection water spray: Use 8 mg / L ozone water to spray the cleaned lotus root for 10 minutes, and the volume of ozone water used is 10 times the volume of the lotus root, and drain the surface water of the lotus root;

[0038] ③Bacteria reduction by gas: At 10°C, use ozone gas with a concentration of 1 mg / L to treat the lotus root obtained in step ① for 10 minutes;

[0039] ④ Bagging and air conditioning: pack the sterilized lotus root in step ③ into a bag, vacuumize it and seal it, so that the pressure inside the bag is 0.05Mpa;

[0040] ⑤ Cooling: Cool the bagged lotus root at -1°C for 50 minutes;

[0041] ⑥Heat insulation and heat preservation: spread the crushed ice with a pa...

Embodiment 3

[0043] Choose rice cake as raw material, follow the steps below:

[0044] ①Take 2kg of freshly steamed rice cake and cool it down to 25°C;

[0045] ②Bacteria reduction by gas: At 10°C, use ozone gas with a concentration of 0.8 mg / L to treat the rice cake obtained in step ① for 5 minutes;

[0046] ③ Bagging and air conditioning: pack the sterilized rice cake in step ② into bags, fill with nitrogen and seal the package, so that the pressure inside the bag is 0.12Mpa;

[0047] ④Cooling: Cool the bagged modified rice cake at -20°C for 20 minutes;

[0048] ⑤Heat insulation: spread crushed ice with a particle size of 2mm on the bottom layer of the foam insulation box (inner cavity size: 300mm×300mm×300mm, thickness 60mm), and then put the rice cake obtained in step ④ on the crushed ice, Then put another layer of crushed ice on top of the rice cake, so that the rice cake and crushed ice are placed at intervals, and the weight ratio of each layer of rice cake to crushed ice is 1:2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com