Kitchen garbage treatment method

A treatment method and technology for kitchen waste, applied in the field of waste treatment and recycling, can solve problems such as cumbersome steps, and achieve the effects of simple steps, processing cycle advantages, and shortening processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

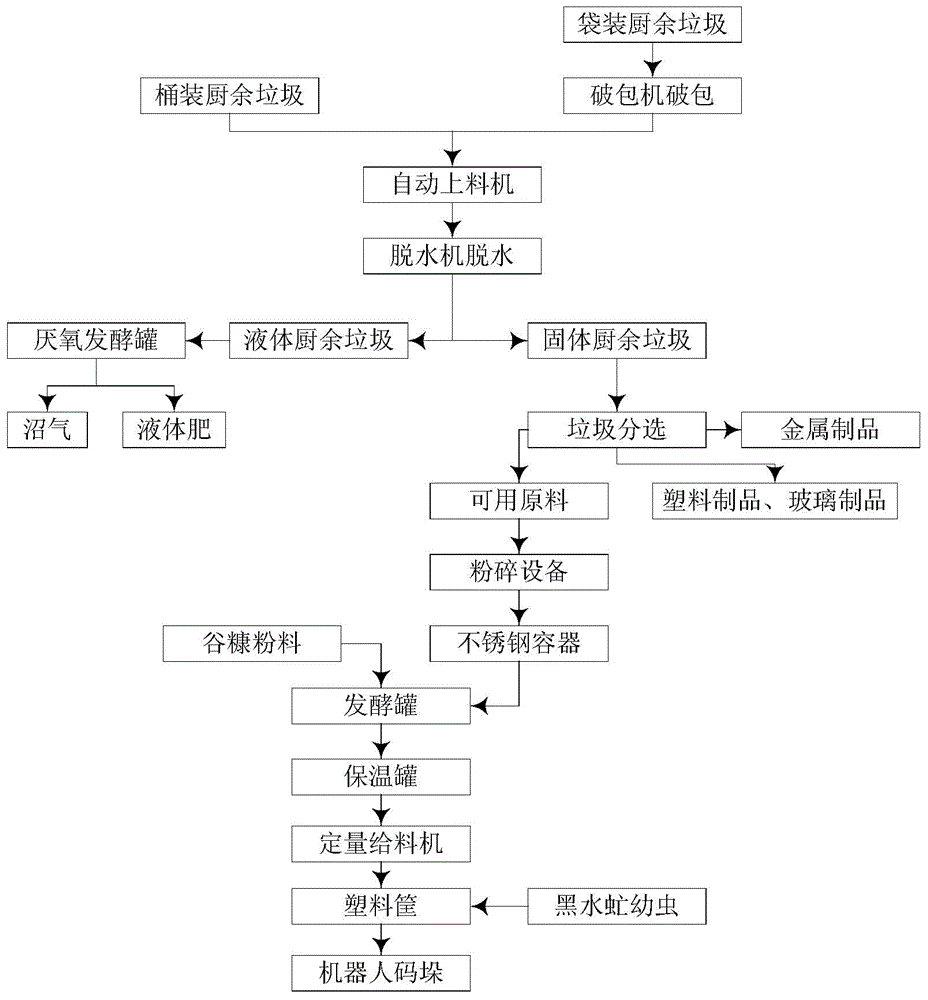

[0037] Step S11: Sorting the kitchen waste to remove metal products, plastic products, glass products and ceramic products contained therein.

[0038] Step S12: Grinding the sorted kitchen waste into a slurry, then adding beneficial bacteria to the slurry for primary fermentation, and after the primary fermentation is completed, heat preservation for secondary fermentation.

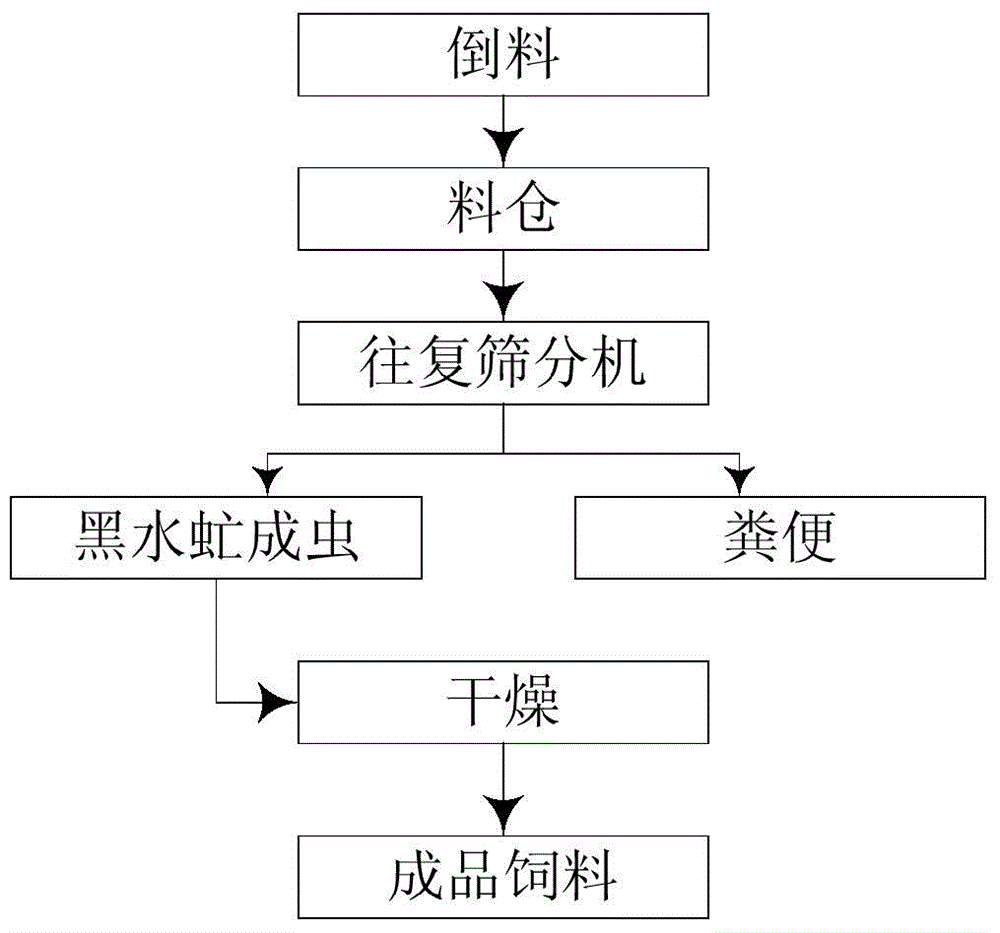

[0039] Step S13: after the secondary fermentation is completed, black soldier fly larvae are inoculated into the slurry for reproduction, and after the reproduction is completed, black soldier fly adult larvae and feces are collected.

Embodiment 2

[0041] Step S21: same as step S11.

[0042] Step S22: In this step, after the sorted kitchen waste is pulverized into a slurry, beneficial bacteria are added for initial fermentation at 50° C. for 3 hours. After the primary fermentation is completed, the fermentation temperature is adjusted to 30° C., and the secondary fermentation is carried out at this temperature, and the time of the secondary fermentation is controlled at 6 hours.

[0043]Step S23: same as step S13.

Embodiment 3

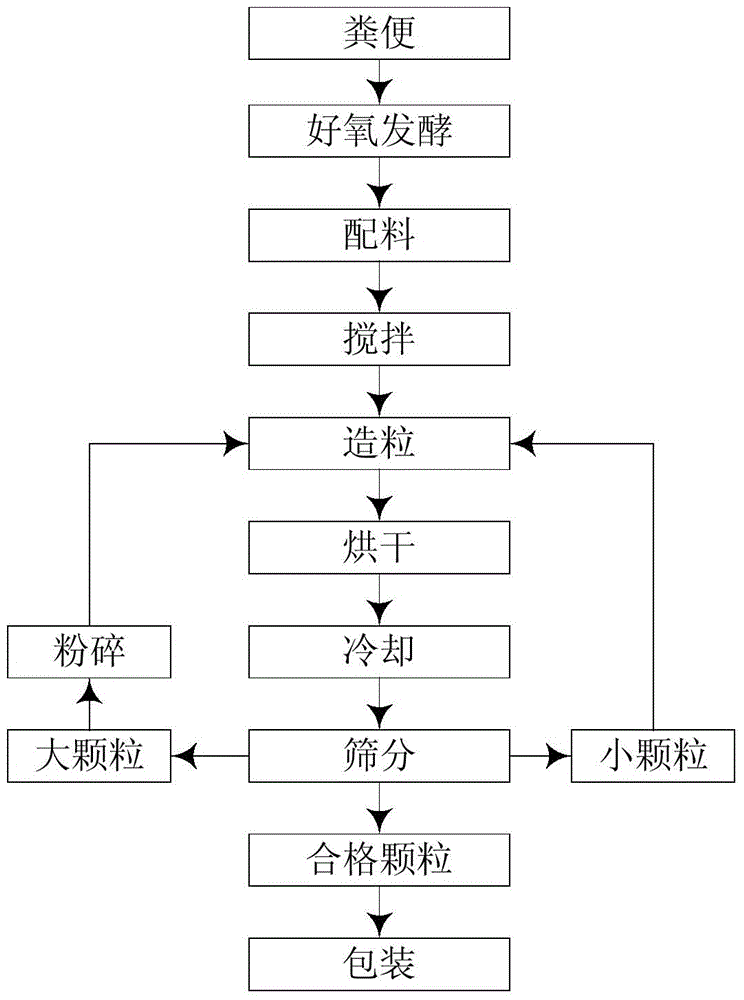

[0045] Step S31: Separating the kitchen waste into solid and liquid to remove the liquid waste; for a large amount of kitchen waste, the collected kitchen waste can be transported to a water separation machine for separation. The separated liquid waste enters anaerobic fermentation, the biogas is used in the production line, and a certain amount of biogas slurry is accumulated to make liquid fertilizer for sale.

[0046] The separated solid kitchen waste is sorted to remove metal products, plastic products, glass products and ceramic products contained in the kitchen waste. The separated metal, plastic, glass and porcelain products are dried and deodorized before being sent to landfill as landfill.

[0047] Step S32: Pulverize the sorted kitchen waste into a slurry, add rice bran whose mass accounts for 25% of the slurry mass, and mix evenly. Then add beneficial bacteria and carry out primary fermentation at 50°C. After 2 hours of primary fermentation, adjust the fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com