A laser processing method and device

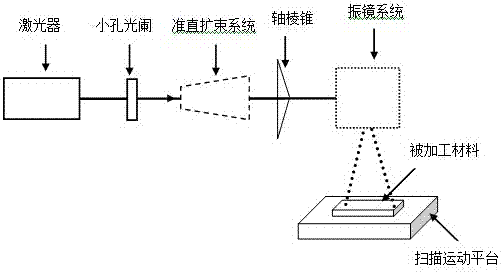

A laser processing method and laser technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing processing costs, large energy difference between edge parts and central parts, affecting the effect of laser processing, etc. The effect of high precision and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A laser processing method, the steps are as follows:

[0029] (1) The laser is turned on by the industrial computer control system, so that the laser emits a laser beam.

[0030] The laser should be selected according to the properties of the material to be processed. According to the properties of the material to be processed, the selection of the laser includes the output wavelength, pulse width, etc. The emission wavelength and pulse width are determined according to the properties of the processed material and the processing accuracy requirements. For example, when the material to be processed is an FPCB flexible circuit board, a 355nm ultraviolet laser should be selected. If there is a higher requirement for processing accuracy, ultrashort pulse lasers such as picoseconds or femtoseconds should be selected as the laser light source.

[0031] (2) Let the laser beam pass through the aperture diaphragm to realize the mode selection and radius control of the laser be...

Embodiment 2

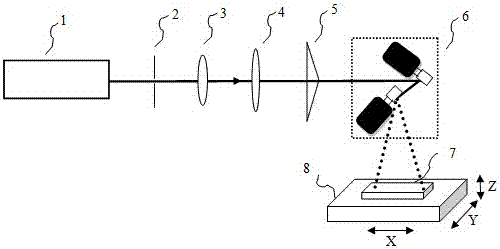

[0040] like figure 2 As shown, a laser processing device includes a laser 1 , an aperture stop 2 , a lens I3 , a lens II4 , an axicon optical element 5 , a galvanometer system 6 and a three-dimensional motion platform 8 . The centers of the laser 1 , pinhole diaphragm 2 , lens I3 , lens II4 , axicon optical element 5 and galvanometer system 6 are on a plane, and the three-dimensional motion platform 8 is located below the galvanometer system 6 .

[0041]The aperture diaphragm 2 is an adjustable diaphragm, and its center is the center of the adjustable diaphragm. The beam emitted by the laser 1 passes through the aperture diaphragm 2 and becomes a single-mode laser beam with adjustable beam radius. The processed beam passes through lens I3 and lens II4. The focal lengths of lens I3 and lens II4 are L1 and L2 respectively. When adjusting the optical path, ensure that the beam passes through the center of lens I3 and lens II4, and the distance between lens I3 and lens II4 is L1...

Embodiment 3

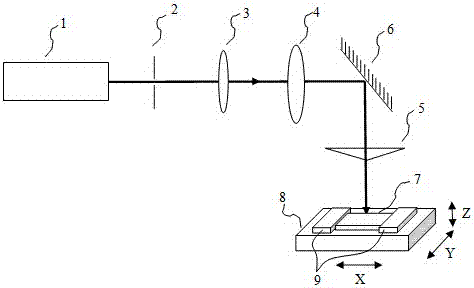

[0045] like image 3 As shown, a laser processing device includes a laser 1, a small aperture stop 2, a lens I3, a lens II4, an axicon optical element 5, a mirror 6, and a three-dimensional motion platform 8. The laser 1, the small hole stop 2 The centers of lens I3, lens II4 and mirror 6 are on the horizontal plane, the plane where the centers of axicon optical element 5 and mirror 6 are located is perpendicular to the horizontal plane, and the three-dimensional motion platform 8 is located below the axicon optical element 5.

[0046] The outgoing light beam of the laser 1 passes through the center of the aperture diaphragm 2, the aperture diaphragm 2 is an adjustable aperture, and its center is the center of the adjustable aperture. When the output beam of the laser 1 is multi-mode, adjust the aperture of the aperture stop 2 to block the high-order mode in the outer ring, and only allow the first-order mode to pass through, eliminating the influence of the laser multi-mode o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com