Production process for modified high-strength rubber wood floor

A kind of rubber wood, high-strength technology, applied in wood processing equipment, wood treatment, manufacturing tools, etc., can solve the problems of poor environmental protection, and achieve the effect of stable size, good anti-termite performance and beautiful color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

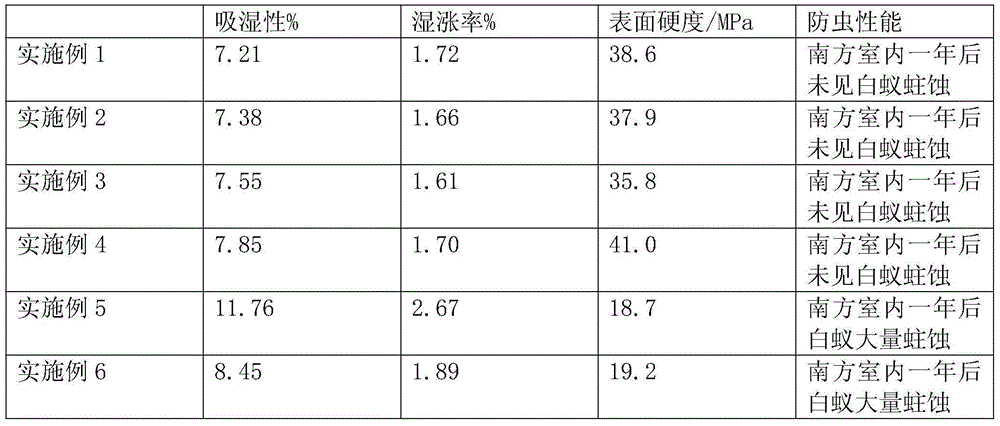

Examples

Embodiment 1

[0023] A method for producing high-strength heat-modified rubber wood flooring, comprising the steps of:

[0024] (1) Timber preparation: sawing rubber wood logs into squares or blanks;

[0025] (2) Vacuum impregnation treatment: put the wooden side or billet stack into the vacuum treatment tank, use boric acid and acetic acid aqueous solution as the treatment solution for vacuum pressure impregnation; wherein the treatment solution is, according to the mass percentage, boric acid 4%, Acetic acid 1.5%; the vacuum degree of the vacuum treatment tank is 0.05, the pressurization pressure is 1.5MPa, and the pressurization time is 10min;

[0026] (3) Pre-drying: drying the wood or billets after the vacuum impregnation treatment to a moisture content of 35%;

[0027] (4) Thermal modification treatment: put the pre-dried wood or billets into the carbonization treatment equipment, use 0.2% trehalose solution as the superheated steam heat transfer medium and protective gas, and heat u...

Embodiment 2

[0031] A method for producing high-strength heat-modified rubber wood flooring, comprising the steps of:

[0032] (1) Timber preparation: sawing rubber wood logs into squares or billets;

[0033] (2) Vacuum impregnation treatment: put the wooden side or billet stack into the vacuum treatment tank, use boric acid and acetic acid aqueous solution as the treatment solution for vacuum pressure impregnation; wherein the treatment solution is, according to the mass percentage, boric acid 5%, acetic acid 1%; the vacuum degree of the vacuum treatment tank is 0.08, the pressurization pressure is 1MPa, and the pressurization time is 15min;

[0034] (3) Pre-drying: drying the wood or billets after the vacuum impregnation treatment to a moisture content of 25%;

[0035] (4) Thermal modification treatment: put the pre-dried wood or billets into the carbonization treatment equipment, use 0.3% trehalose solution as the superheated steam heat transfer medium and protective gas, and heat up a...

Embodiment 3

[0039] A method for producing high-strength heat-modified rubber wood flooring, comprising the steps of:

[0040] (1) Timber preparation: sawing rubber wood logs into squares or blanks;

[0041] (2) Vacuum impregnation treatment: put the wooden side or billet stack into the vacuum treatment tank, use boric acid and acetic acid aqueous solution as the treatment solution for vacuum pressure impregnation; wherein the treatment solution is, according to the mass percentage, boric acid 4%, Acetic acid 1.4%; the vacuum degree of the vacuum treatment tank is 0.06, the pressurization pressure is 1.3MPa, and the pressurization time is 11min;

[0042] (3) Pre-drying: drying the wood or billets after the vacuum impregnation treatment to a moisture content of 30%;

[0043] (4) Thermal modification treatment: put the pre-dried wood or billets into the carbonization treatment equipment, use 0.2% trehalose solution as the superheated steam heat transfer medium and protective gas, and heat u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com