Coal-based ethylene glycol sewage treatment method and system

A sewage treatment method and sewage treatment system technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve high energy consumption and operating costs, high daily management requirements, Incomplete biodegradation and other problems, to achieve the effect of small footprint, improved treatment efficiency, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

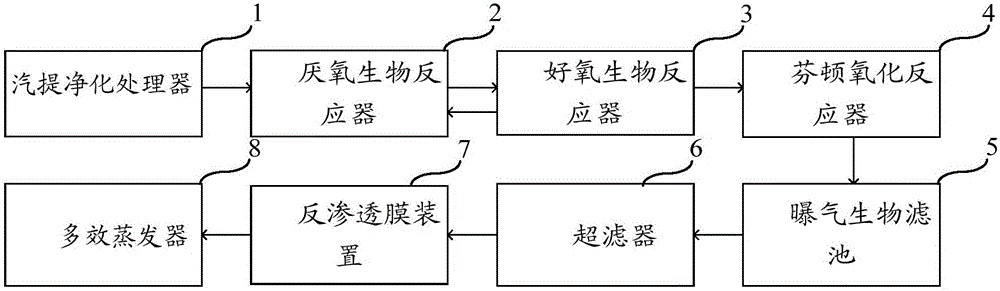

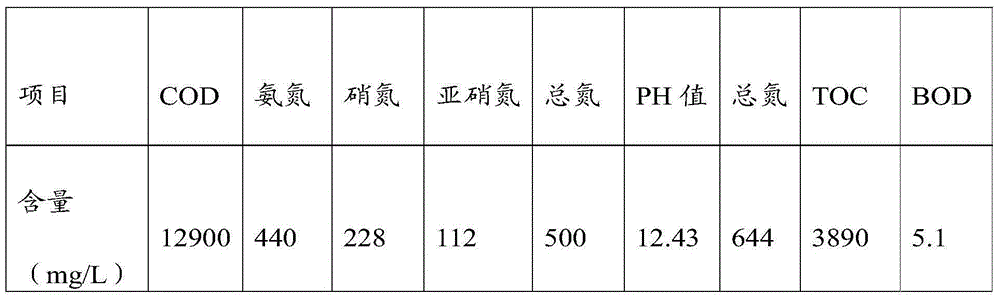

[0059] A method for the treatment of coal-based ethylene glycol sewage, comprising the following steps:

[0060] Carrying out stripping and purifying treatment of the coal-based ethylene glycol wastewater, recovering organic matter in the stripping gas, and obtaining primary treated wastewater;

[0061] Anaerobic biological treatment is carried out on the wastewater of the primary treatment to obtain the wastewater of the secondary treatment;

[0062] Carrying out aerobic biological treatment to the wastewater of the secondary treatment to obtain the wastewater of the tertiary treatment;

[0063] Carrying out Fenton oxidation treatment to the wastewater treated in the third stage to obtain the wastewater treated in the fourth stage;

[0064] The biological aerated filter is used to treat the waste water of the fourth stage treatment to obtain the waste water of the fifth stage treatment;

[0065] Ultrafiltration and reverse osmosis treatment are performed sequentially on the...

Embodiment 2

[0067] A method for the treatment of coal-based ethylene glycol sewage, comprising the following steps:

[0068] Carrying out stripping and purifying treatment of the coal-based ethylene glycol wastewater, recovering organic matter in the stripping gas, and obtaining primary treated wastewater;

[0069] Anaerobic biological treatment is carried out on the wastewater of the primary treatment to obtain the wastewater of the secondary treatment;

[0070] Carrying out aerobic biological treatment to the wastewater of the secondary treatment to obtain the wastewater of the tertiary treatment, and returning a part of it to the anaerobic biological treatment step;

[0071] Carrying out Fenton oxidation treatment to the remaining wastewater treated in the third stage to obtain wastewater treated in the fourth stage;

[0072] The biological aerated filter is used to treat the waste water of the fourth stage treatment to obtain the waste water of the fifth stage treatment;

[0073] Pe...

Embodiment 3

[0081] A coal-to-ethylene glycol sewage treatment system, including sequentially connected stripping purification processor, anaerobic bioreactor, aerobic bioreactor, Fenton oxidation reactor, aerated biological filter, ultrafilter and reverse permeable membrane device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com