Low-melting glass powder of crystalline silicon solar energy battery front side silver paste and preparation method thereof

A technology of solar cells and low-melting glass, applied in the field of electronic materials, can solve problems such as difficulty in obtaining performance, and achieve the effects of improving photoelectric conversion efficiency and service life, reducing lead content, and reducing risks

Active Publication Date: 2015-11-25

上海太阳能工程技术研究中心有限公司

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

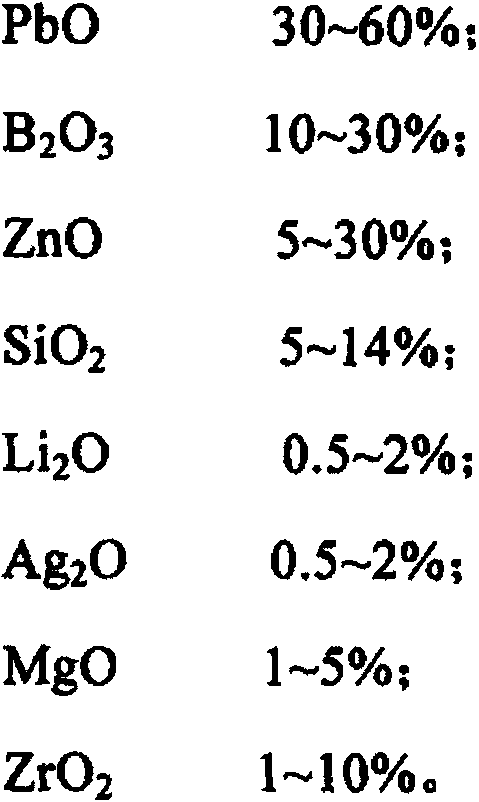

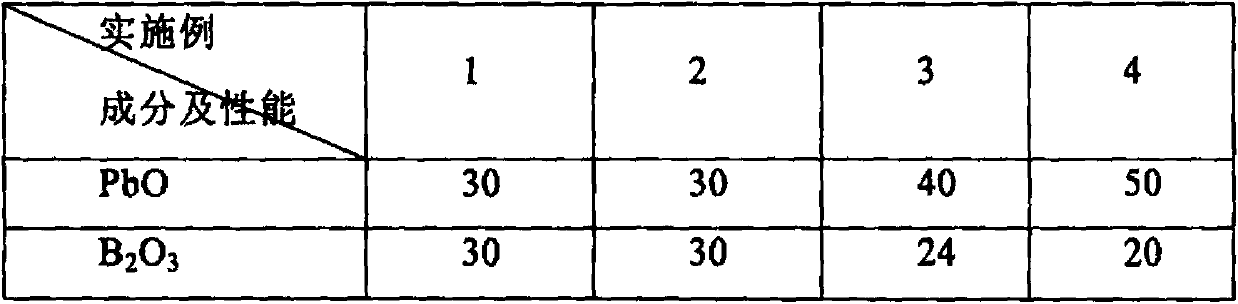

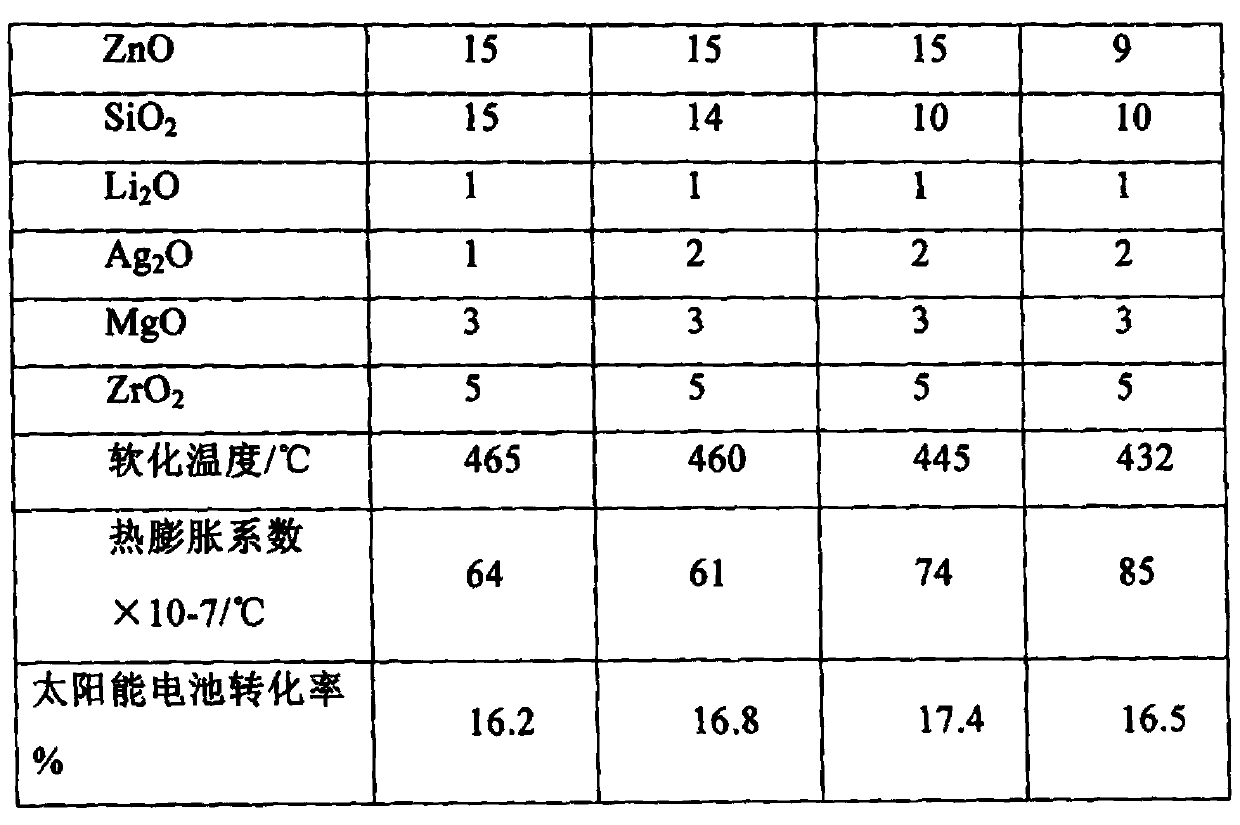

The invention provides a low-melting glass powder of crystalline silicon solar energy battery front side silver paste, and the powder is processed from the following substances in percentage by weight: 30-60% of PbO, 10-30% of B2O3, 5-30% of ZnO, 5-14% of SiO2, 0.5-2% of Li2O, 0.5-2% of Ag2O, 1-5% of MgO and 1-10% of ZrO. The preparation method comprises the following steps: 1. weighing materials, and uniformly mixing the materials in a ceramic mortar; 2. pouring the mixed powder into a corundum crucible, covering the crucible with a cover, and placing the crucible into a muffle furnace for fusion at an assigned furnace temperature; 3. carrying out water quenching of the fused glass liquid; 4. carrying out a drying; 5. milling and crushing the glass material after water quenching. The prepared glass powder has a suitable softening temperature, and has a good wetting capability for silver and silicon, simultaneously the glass contains silver oxide, and thereby better conveying and precipitating silver crystal grains in the sintering process, obtaining more contact points, improving the generation probability of tunnel effect, and reducing the contact resistor. Because the lead content is low, corrosion to silicon is reduced and possibility for breakdown of PN junction is effectively decreased, and thereby improving photoelectric conversion efficiency and life of solar energy battery in the prerequisite for guarantying the contact resistor.

Description

technical field The invention relates to electronic materials, in particular to a glass powder used for front silver paste of crystalline silicon solar cells and a preparation method thereof. Background technique Solar power generation has many incomparable advantages. Solar energy has the characteristics of abundant resources and inexhaustible use. At the same time, solar power generation equipment has a simple structure, easy installation and transportation, short construction period, simple maintenance, convenient use and safety. Moreover, there is no need to consume fuel during the power generation process, and there are no mechanical rotating parts, which will not cause any pollution and damage to the environment. Therefore, solar power generation has obvious economic benefits. Crystalline silicon solar cell power generation is still the main way of solar power generation due to its high conversion efficiency, long life and low cost. The metallization of the front ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C12/00

Inventor 任益超郑建华张愿成敖毅伟袁晓赵欣侃

Owner 上海太阳能工程技术研究中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com