Biological type organic-inorganic compound fertilizer and method for preparing same

A compound fertilizer, biological technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of soil biological environment damage, impact on food safety, soil secondary pollution, etc., to achieve convenient transportation and storage, no environmental pollution, A wide range of practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An organic-inorganic compound fertilizer, comprising: 30-35 parts by weight of cassava residues, 10 parts by weight of urea, 20 parts by weight of ammonium chloride, 5.5 parts by weight of ammonium sulfate, 10 parts by weight of monoammonium phosphate, 10 parts by weight of The calcium superphosphate of 10 parts by weight, the potassium chloride of 10 parts by weight and the arbuscular mycorrhizal fungus agent of 0.12 parts by weight.

Embodiment 2

[0031] An organic-inorganic compound fertilizer, comprising: 32 to 37 parts by weight of organic fertilizer, 15 parts by weight of urea, 25 parts by weight of ammonium chloride, 5 parts by weight of ammonium sulfate, 20 parts by weight of monoammonium phosphate, 12 parts by weight of part of calcium superphosphate, 15 parts by weight of potassium chloride and 0.1 part by weight of arbuscular mycorrhizal fungal agent; the organic fertilizer is obtained after mixed fermentation of cassava residue and rice straw, and the ratio of cassava residue and rice straw is 5:1 The mass ratio is mixed.

Embodiment 3

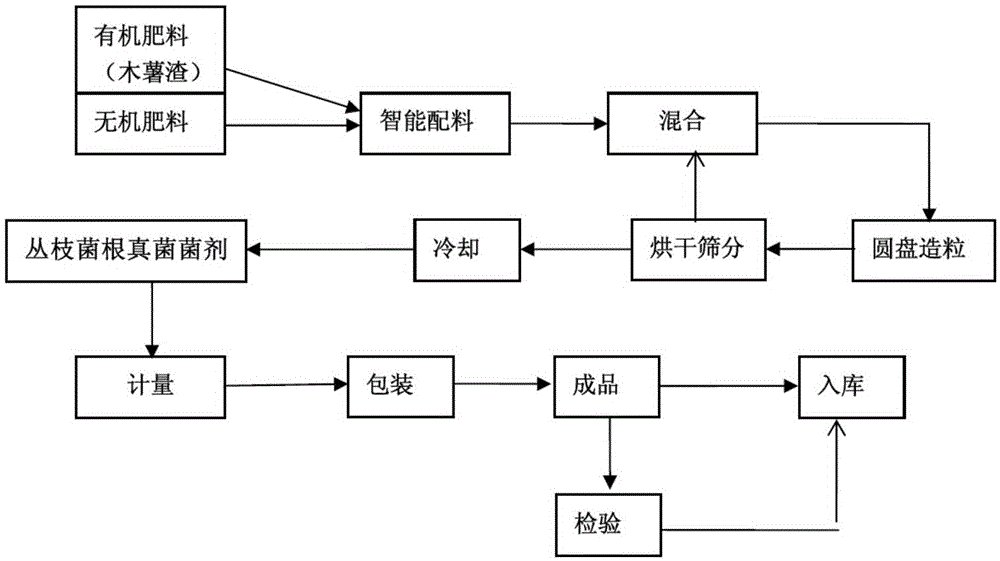

[0033] Produce the organic-inorganic compound fertilizer in implementing 2, flow process is as figure 1 Shown:

[0034] Fermentation preparation of organic fertilizer: First, fresh cassava dregs are pressed by a solid-liquid separator or dried naturally to reduce their water content to 30% to 40%, and then the pure cassava dregs or cassava dregs and rice straw are mixed according to the weight ratio of 5:1 Mix and then ferment for 10 to 20 days. During the fermentation process, when the temperature of the fermentation material rises to 60°C, the compost is turned over, and the compost is turned 2 to 3 times during the fermentation period. After the fermentation is over, spread out the stacked material and dry it until the water content of the organic fertilizer is ≤20%, that is, pure cassava dregs or organic fertilizer fermented with cassava dregs and rice and wheat straws are obtained for future use.

[0035] Feeding: Weigh each raw material according to the composition and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com