Preparation method of porous ionic type electrically-driven polymer intelligent material

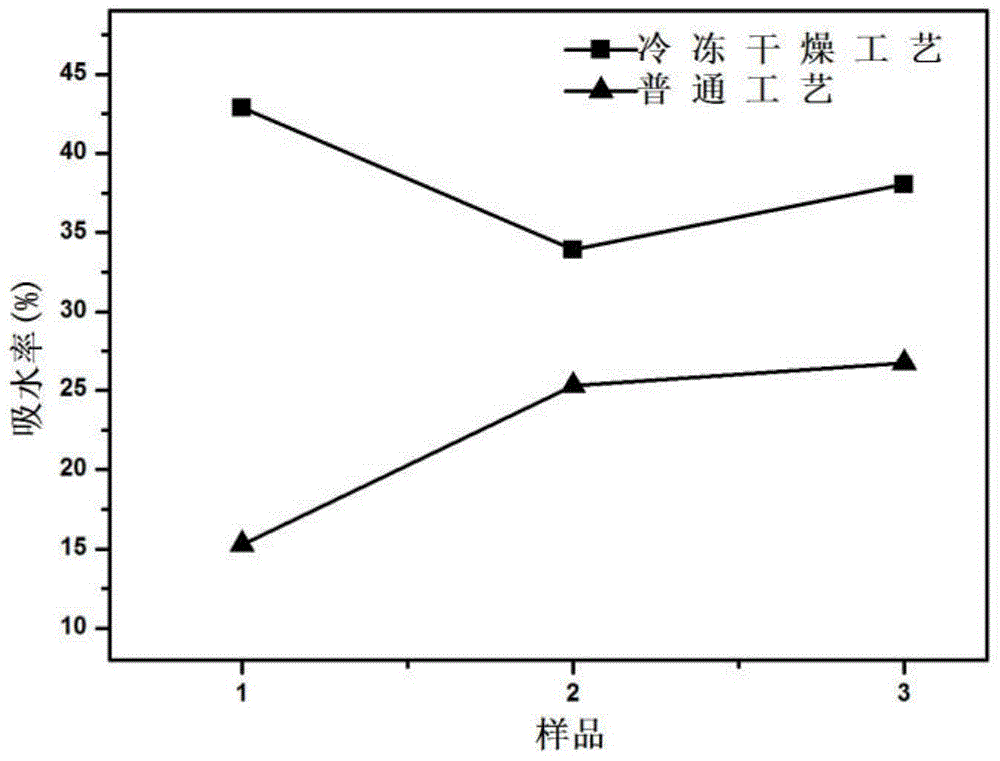

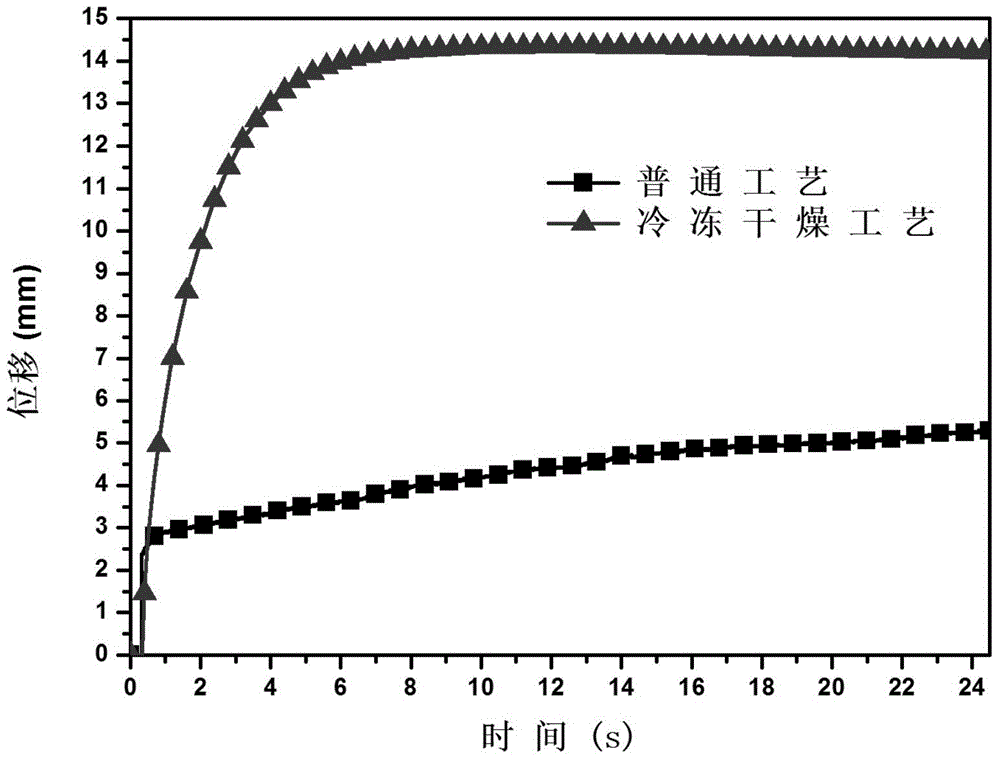

An ionic polymer and smart material technology, which is applied in the field of preparation of porous ionic electro-actuated polymer smart materials, can solve the problems of complex process and limited improvement of the driving performance of porous smart materials, and achieves simple process and enhanced electrical conductivity. , the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1) Pour Nafion solution (produced by DuPont) and ethylene glycol into the mold for ultrasonic vibration treatment for 30min, mix evenly, and obtain the casting liquid; wherein, the volume of ethylene glycol is 1 / 10 of the volume of the Nafion solution;

[0050] 2) Vacuum melting and casting the mold containing the casting liquid in a vacuum drying oven at 120°C for 12 hours to obtain the Nafion matrix;

[0051] 3) The Nafion matrix was pre-frozen with liquid nitrogen for 30 min, then freeze-dried in a freeze-drying oven, and dried under vacuum from -80 °C at a heating rate of 1.5 °C / h for 23 h to obtain a porous Nafion matrix.

Embodiment 2

[0053] 1) Nafion solution (produced by DuPont) and dimethyl sulfoxide are poured into the mold and mixed uniformly to obtain a casting liquid; wherein, the volume of dimethyl sulfoxide is 1 / 10 of the volume of the Nafion solution;

[0054] 2) Vacuum melting and casting the mold containing the casting liquid in a vacuum drying oven at 120°C for 24 hours to obtain the Nafion matrix;

[0055] 3) The Nafion matrix was pre-frozen with liquid nitrogen for 15 minutes, then freeze-dried in a freeze-drying oven, and dried under vacuum from -70°C at a heating rate of 2°C / h for 24h to obtain a porous Nafion matrix.

Embodiment 3

[0057] 1) Nafion solution (prepared according to the preparation method in the patent CN102875940A) and dimethylformamide are poured into the mold and mixed uniformly to obtain a casting liquid; wherein, the volume of dimethylformamide is 1% of the volume of the Nafion solution / 10;

[0058] 2) Vacuum melting and casting the mold containing the casting liquid in a vacuum drying oven at 120°C for 20 hours to obtain the Nafion matrix;

[0059] 3) The Nafion matrix was pre-frozen with liquid nitrogen for 20 minutes, then freeze-dried in a freeze-drying oven, and dried at a temperature range of -80°C under vacuum for 72h at a heating rate of 1.5°C / h to obtain a porous Nafion matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com