Antibacterial transparent dressing, preparing method of antibacterial transparent dressing and application of antibacterial transparent dressing

A transparent and reactive technology, applied in the field of medical devices made of polymer materials, can solve problems such as bloodstream infection and bacterial residue, and achieve the effect of facilitating healing, long-term antibacterial performance, and controlled release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

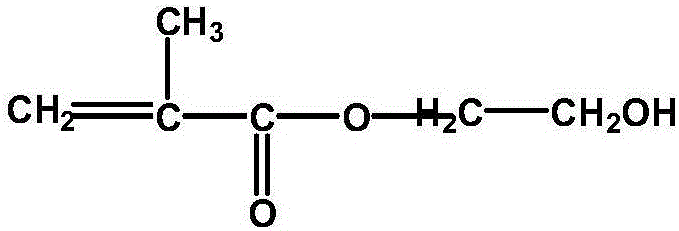

[0051] Step 1, take 60 parts of 2-hydroxyethyl methacrylate, 0.1 part of azobisisobutyronitrile, 0.1 part of ethylene glycol dimethacrylate, 2 parts of chlorhexidine gluconate, 1 part of ethylene glycol and water 38 parts of the mixed solution of 1 were stirred at room temperature and 4000r / min for 30min to make a mixed solution;

[0052] Step 2, sealing the above mixed solution in a container, placing it in a 70°C water bath, stirring, reacting for 8 hours, and then stopping the reaction to obtain a polymer;

[0053] Step 3: Put the polymer prepared by the above reaction in a container filled with 100 mL of water, and change the water every 3 hours until 3 days to obtain a gel pad.

[0054] In step 4, the gel liner is adhered to the surface of the polyurethane transparent film through a medical pressure-sensitive adhesive by extrusion or pasting, and fixed to obtain an antibacterial transparent dressing.

Embodiment 2

[0056] Step 1, take 40 parts of 2-hydroxyethyl methacrylate, 0.02 part of azobisisobutyronitrile, 0.1 part of ethylene glycol dimethacrylate, 0.5 part of chlorhexidine gluconate, 1 part of ethylene glycol and water 60 parts of the mixed solution of 1 were stirred at room temperature and 4000r / min for 30min to make a mixed solution;

[0057] Step 2, sealing the above mixed solution in a container, placing it in a 70°C water bath, stirring, reacting for 8 hours, and then stopping the reaction to obtain a polymer;

[0058] Step 3: Put the polymer prepared by the above reaction in a container filled with 100 mL of water, and change the water every 3 hours until 3 days to obtain a gel pad.

[0059] In step 4, the gel liner is adhered to the surface of the polyurethane transparent film through a medical pressure-sensitive adhesive by extrusion or pasting, and fixed to obtain an antibacterial transparent dressing.

Embodiment 3

[0061] Step 1, take 80 parts of 2-hydroxyethyl methacrylate, 0.5 parts of azobisisobutyronitrile, 0.5 parts of ethylene glycol dimethacrylate, 5 parts of chlorhexidine gluconate, 1 part of ethylene glycol and water 14 parts of the mixed solution of 1 were stirred at room temperature and 4000r / min for 30min to make a mixed solution;

[0062] Step 2, sealing the above mixed solution in a container, placing it in a 70°C water bath, stirring, reacting for 8 hours, and then stopping the reaction to obtain a polymer;

[0063] Step 3: Put the polymer prepared by the above reaction in a container filled with 100 mL of water, and change the water every 3 hours until 3 days to obtain a gel pad.

[0064] In step 4, the gel liner is adhered to the surface of the polyurethane transparent film through a medical pressure-sensitive adhesive, and fixed to obtain an antibacterial transparent dressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com