Long glass fiber reinforced TPU non-slip soles and preparation method thereof

A long glass fiber and anti-skid technology, applied in the field of long glass fiber reinforced TPU anti-skid soles and their preparation, can solve the problems of no research on the influence of fiber anti-skid performance, no description of anti-skid performance, no expression of anti-skid effect, etc., to facilitate automatic processing. The effect of engineering control, increasing quality and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

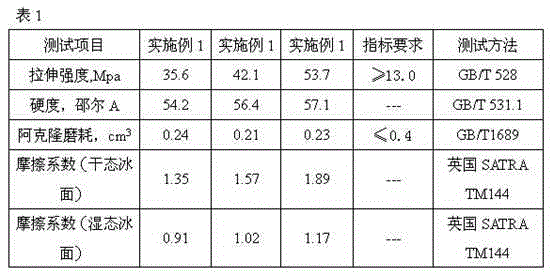

Examples

Embodiment 1

[0011] Embodiment 1 of the present invention: long glass fiber reinforced TPU non-slip sole, calculated by mass parts, including 100 parts of thermoplastic polyurethane elastic plastic, 20 parts of glass fiber, 3 parts of bridging agent, 0.8 part of bridging aid, 5 parts of phase Compatible agent, 2 parts of active agent, 0.5 part of antioxidant, 0.5 part of fluidity aid, 0.5 part of anti-wear agent and 2 parts of blowing agent; Described bridging agent is (2-tert-butylperoxyisopropyl base)-3-isopropenylbenzene; the bridging aid is triallyl isocyanurate; the compatibilizer is styrene-maleic anhydride copolymer; the active agent is Zinc stearate.

[0012] The preparation method of long glass fiber reinforced TPU non-slip soles is to dry thermoplastic polyurethane elastic plastics and compatibilizers respectively for subsequent use; take the dried thermoplastic polyurethane elastic plastics and compatibilizers, bridging agents, bridging auxiliary agents, active agents, flowable ...

Embodiment 2

[0013] Embodiment 2 of the present invention: long glass fiber reinforced TPU non-slip sole, characterized in that: calculated in parts by mass, including 90 parts of thermoplastic polyurethane elastic plastics, 30 parts of glass fibers, 2.5 parts of bridging agent, and 0.5 part of bridging aid , 6 parts of compatibilizer, 1 part of active agent, 0.6 part of antioxidant, 0.4 part of fluidity aid, 0.6 part of anti-wear agent and 2.5 parts of blowing agent; Described bridging agent is (2-tert-butyl Peroxyisopropyl)-3-isopropenylbenzene; the bridging aid is triallyl isocyanurate; the compatibilizer is styrene-maleic anhydride copolymer; the The active agent is zinc stearate.

[0014] The preparation method is the same as in Example 1.

Embodiment 3

[0015] Embodiment 3 of the present invention: long glass fiber reinforced TPU non-slip sole, characterized in that: calculated in parts by mass, it includes 110 parts of thermoplastic polyurethane elastic plastic, 40 parts of glass fiber, 4 parts of bridging agent, and 1 part of bridging aid , 4 parts of compatibilizers, 3 parts of active agents, 0.4 parts of antioxidants, 0.6 parts of fluidity aids, 0.1 parts of anti-wear agents and 1 part of foaming agent; the bridging agent is (2-tert-butyl Peroxyisopropyl)-3-isopropenylbenzene; the bridging aid is triallyl isocyanurate; the compatibilizer is styrene-maleic anhydride copolymer; the The active agent is zinc stearate.

[0016] The preparation method is the same as in Example 1.

[0017] In the above examples, the grade of TPU is 2103-80AE, the grade of continuous glass fiber is 988, the grade of styrene-maleic anhydride copolymer is 4M / SSD5-214, the grade of antioxidant is PUB350, and the fluidity aid The grade of the agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com