A kind of method of Fischer-Tropsch synthesis

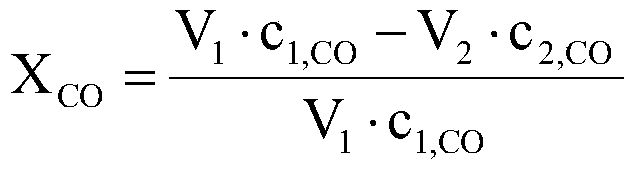

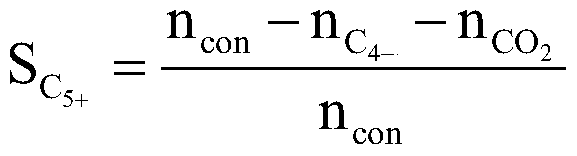

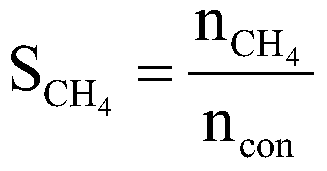

A technology for Fischer-Tropsch synthesis and synthesis gas, which is used in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., and can solve the problems of low CO conversion rate and C5+ selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is used to illustrate the Fischer-Tropsch synthesis method provided by the present invention.

[0034] (1) Preparation of Fischer-Tropsch synthesis catalyst:

[0035] 10% by weight of β-molecular sieve is mixed with 90% by weight of pseudo-boehmite (Sasol company C1 powder) and extruded with a circular orifice plate with a diameter of 1.4 mm, and then the extruded rod is dried at 120 ° C for 4 hours, and then calcined at 600°C for 4 hours to obtain a carrier. Next, an eggshell catalyst was prepared according to the method disclosed in Example 6 of CN101462079A to obtain a Fischer-Tropsch synthesis catalyst A. The content of the active metal component cobalt in the obtained Fischer-Tropsch synthesis catalyst determined by X-ray fluorescence method was 16% by weight. It can be observed with the naked eye that the active metal component is distributed in an eggshell on the Fischer-Tropsch synthesis catalyst (observed after crushing), and the thickness of ...

Embodiment 2

[0045] This embodiment is used to illustrate the Fischer-Tropsch synthesis method provided by the present invention.

[0046] (1) Preparation of Fischer-Tropsch synthesis catalyst:

[0047]30% by weight of ZSM-22 is mixed with 70% by weight of pseudo-boehmite powder (SB powder purchased from Sasol Company) and then extruded into a circular orifice with a diameter of 1.4 mm, then extruded in Dry at 120°C for 4 hours, and then bake at 600°C for 4 hours to obtain a carrier. Next, an eggshell catalyst was prepared according to the method disclosed in Example 6 of CN101462079A to obtain a Fischer-Tropsch synthesis catalyst B. The content of the active metal component cobalt in the obtained Fischer-Tropsch synthesis catalyst determined by X-ray fluorescence method was 16% by weight. It can be observed with the naked eye that the active metal component is distributed in an eggshell on the Fischer-Tropsch synthesis catalyst (observed after crushing), and the thickness of the shell d...

Embodiment 3

[0051] This embodiment is used to illustrate the Fischer-Tropsch synthesis method provided by the present invention.

[0052] (1) Preparation of Fischer-Tropsch synthesis catalyst:

[0053] 10% by weight of β-molecular sieve is mixed with 90% by weight of pseudo-boehmite (Sasol company C1 powder) and extruded with a circular orifice plate with a diameter of 1.4 mm, and then the extruded rod is dried at 120 ° C for 4 hours, and then calcined at 600°C for 4 hours to obtain a carrier. Next, an eggshell-type catalyst was prepared according to the method disclosed in Example 6 of CN101462079A, and the impregnation solution was replaced with ruthenium nitrate solution of the same concentration and volume to obtain Fischer-Tropsch synthesis catalyst C. The content of the active metal component ruthenium in the obtained Fischer-Tropsch synthesis catalyst determined by X-ray fluorescence method was 2% by weight. It can be observed with the naked eye that the active metal component is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com