Propane dehydrogenation catalyst with Mg and/or Ti modified spherical mesoporous material as carrier as well as preparation method and application of propane dehydrogenation catalyst

A mesoporous material, propane dehydrogenation technology, applied in the field of propane dehydrogenation to propylene, can solve the problem of low propylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] According to a preferred embodiment of the present invention, the step (c) includes: in the presence of an inert gas, in a stirred reactor, add the electron donor solvent tetrahydrofuran (THF), and control the reactor temperature to 25- 40°C, quickly add magnesium chloride and titanium tetrachloride when the stirring is turned on, adjust the system temperature to 60-75°C and react at a constant temperature for 1-5 hours until the magnesium chloride and titanium tetrachloride are completely dissolved, and the mixture containing magnesium chloride and titanium tetrachloride is obtained. of organic solutions. The organic solution containing magnesium chloride and titanium tetrachloride as described above is mixed with the spherical mesoporous material obtained in step (b) to perform the first impregnation treatment, and the ratio between the components is controlled to be, relative to 1 mole of titanium, The magnesium element content is 0.5-50 moles, preferably 1-10 moles,...

Embodiment 1

[0080] This example is used to illustrate the propane dehydrogenation catalyst and its preparation method.

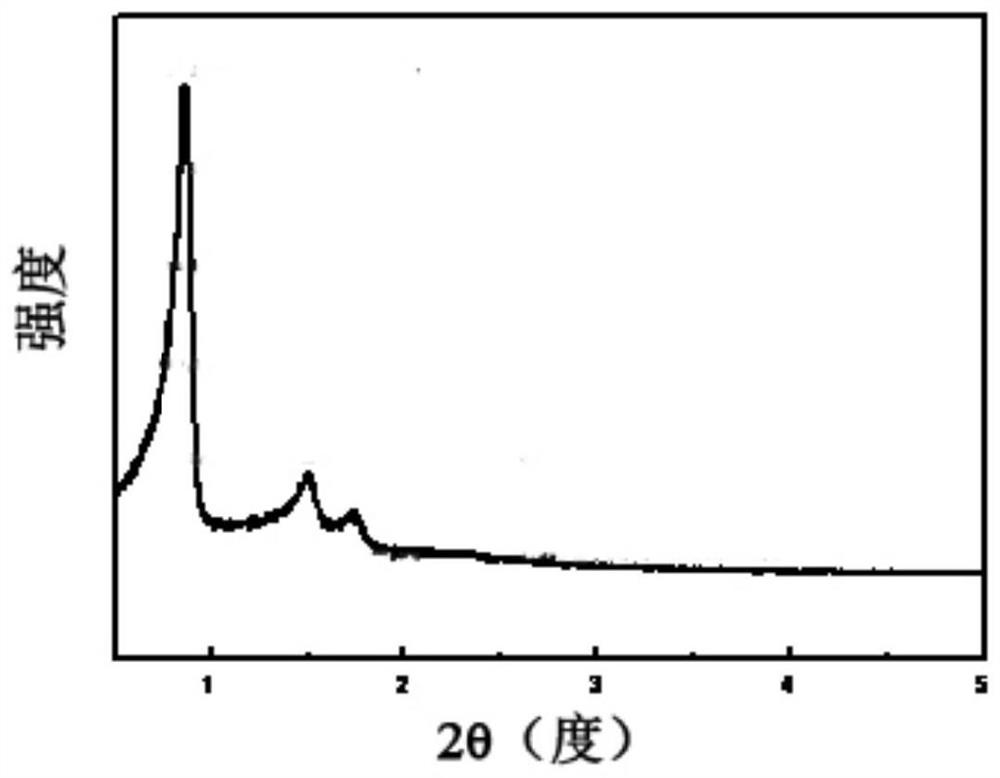

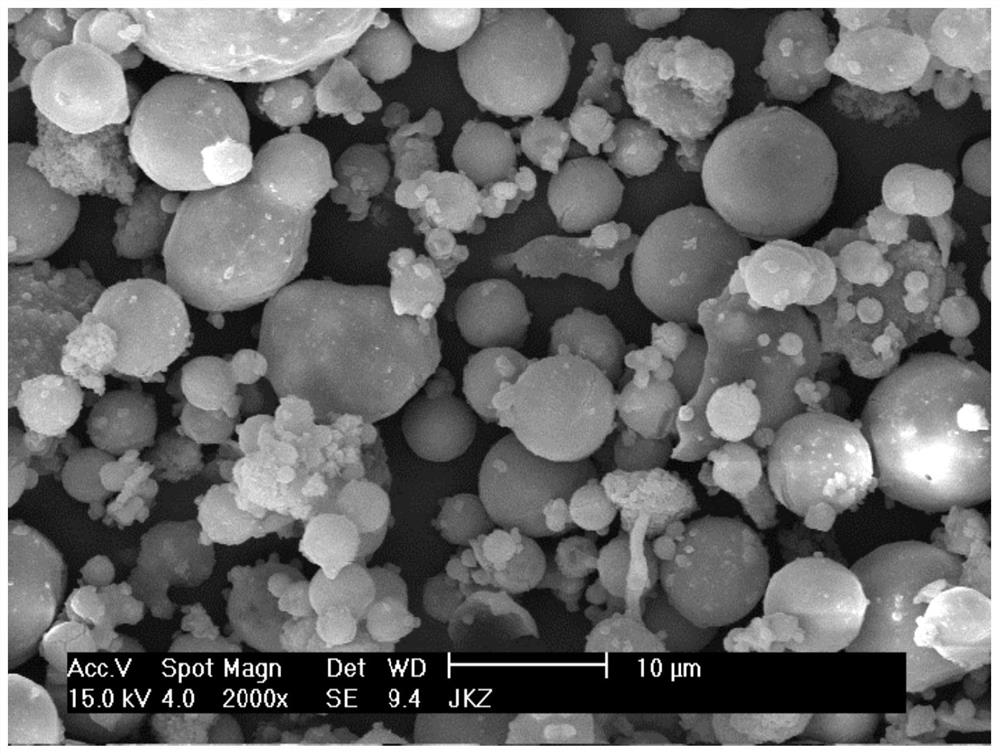

[0081] (1) Preparation of spherical mesoporous materials

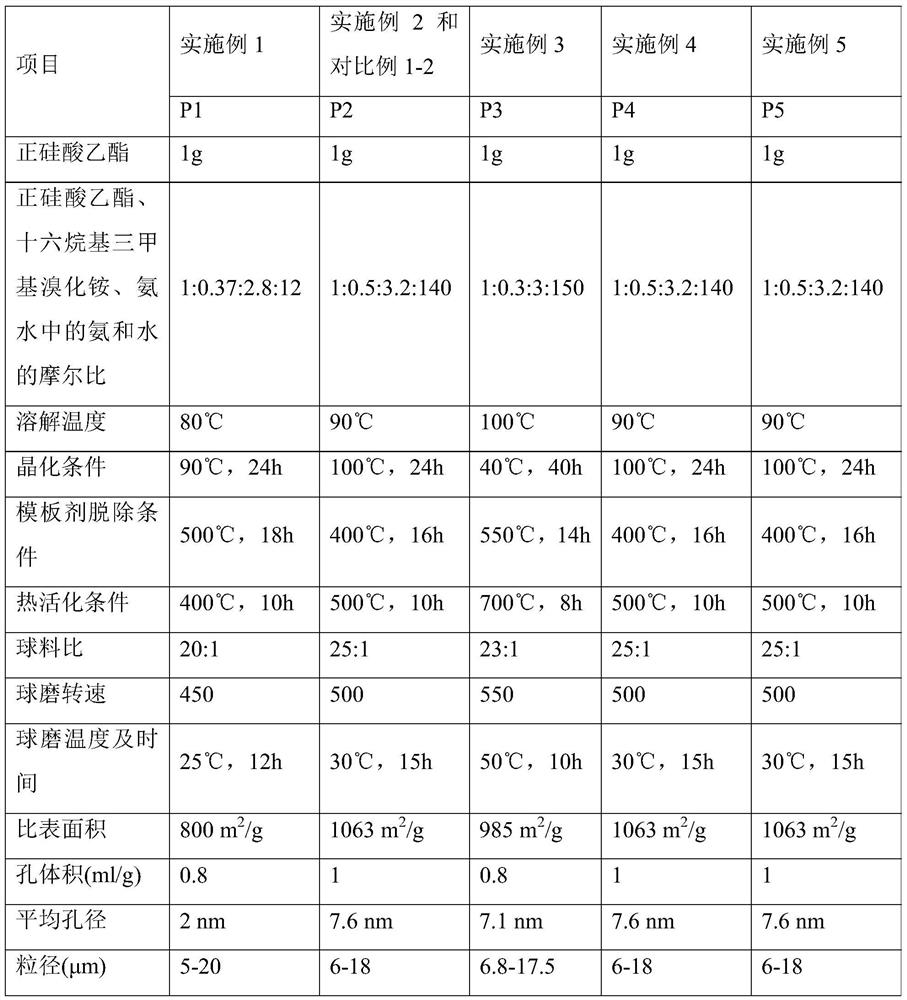

[0082]Hexadecyltrimethylammonium bromide and tetraethyl orthosilicate are added to the ammonia solution with a concentration of 25% by weight, wherein the addition of ethyl orthosilicate is 1g, and ethyl orthosilicate, hexadecane The molar ratios of trimethylammonium bromide, ammonia in ammonia water and water are listed in Table 1, and stirred at 80°C for 24h, then the resulting solution was transferred to a polytetrafluoroethylene-lined reactor, at 90 ℃ for 24 hours, followed by filtration and washing with deionized water for 4 times until the pH of the solution was 7, and then suction filtration to obtain a filter cake of mesoporous material with a two-dimensional hexagonal pore structure. Then, the filter cake was calcined in a muffle furnace at 500° C. for 18 hours to remove the template agent to obtain th...

Embodiment 2-5

[0093] Change the preparation process of the spherical mesoporous material P1 in Example 1 and the amount of each raw material and the operating condition parameters in the preparation process of the propane dehydrogenation catalyst, and carry out Examples 2-5 to obtain spherical mesoporous materials P2~P5, Mg and Ti-modified spherical mesoporous material supports C2-C5, and propane dehydrogenation catalysts Cat-2-Cat-5. Cat-2 to Cat-5 were respectively used to catalyze the reaction of propane dehydrogenation to propylene according to the method of Example 1.

[0094] Table 1 lists the dosage of each component, operating condition parameters and pore structure parameters of the spherical mesoporous materials P2-P5 in the preparation process of the spherical mesoporous materials P2-P5.

[0095] Table 2 lists the preparation process parameters of Mg and Ti modified spherical mesoporous material carriers (including the type and amount of precursors of magnesium and titanium compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com