Lubricant for natural casings and preparation method thereof

A casing lubricant, a natural technology, applied in the direction of lubricating compositions, etc., to achieve the effects of overcoming the influence of the casing, inhibiting oxidation, and reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

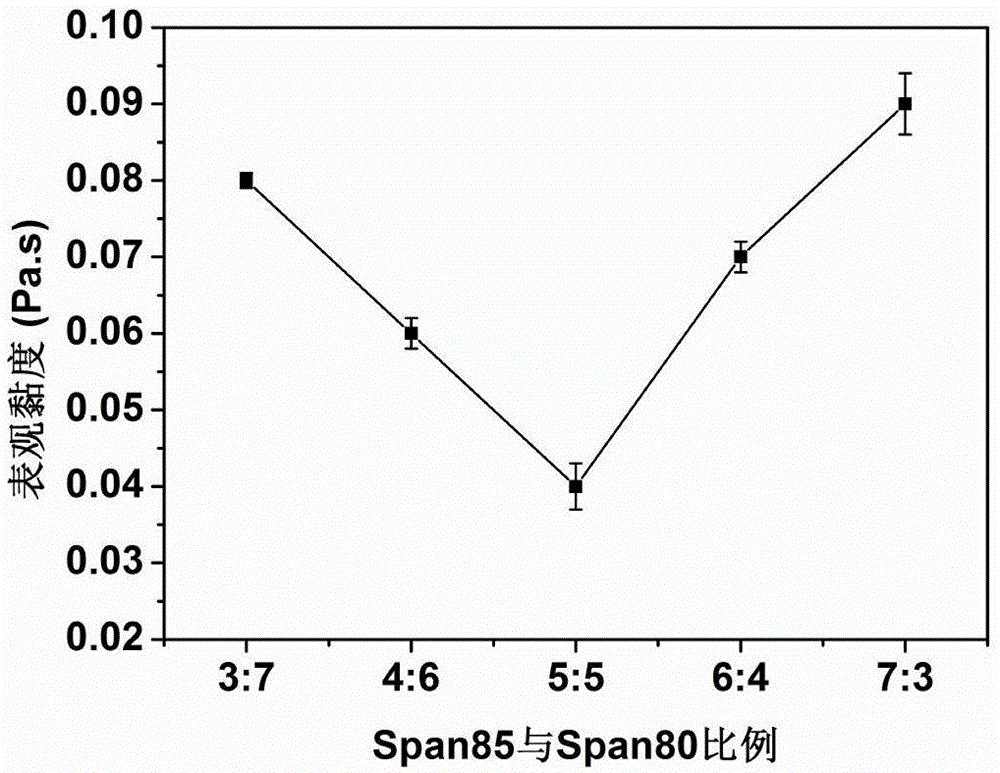

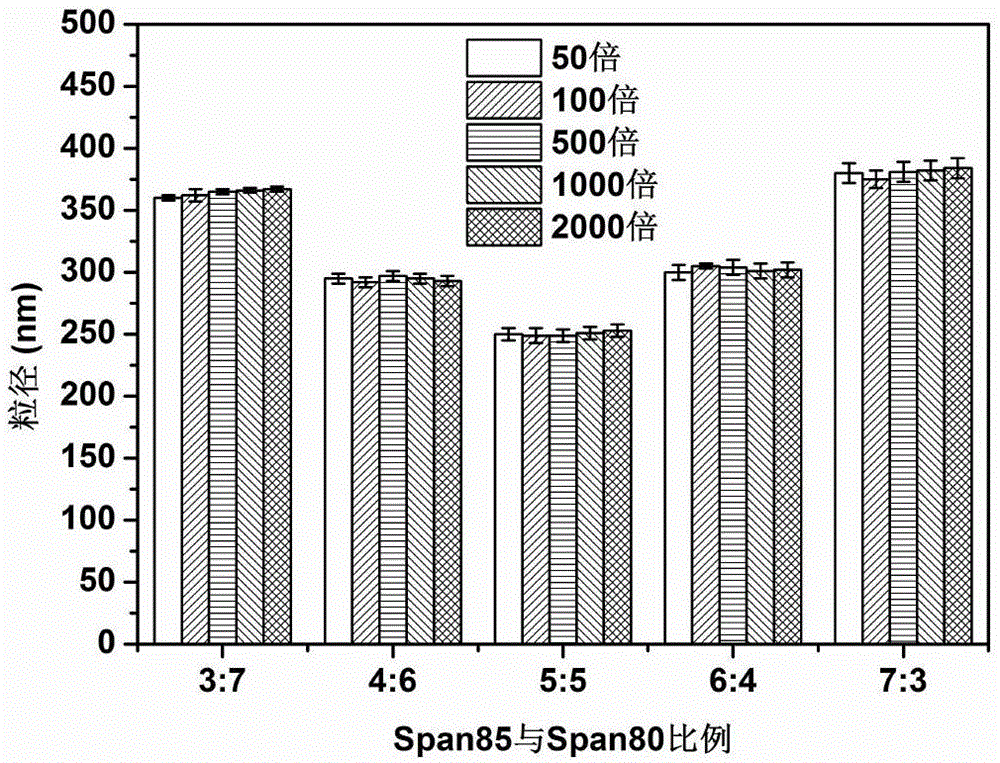

[0030] (1) Preparation of lubricant: with 3.2% sorbitan trioleate, 4.8% sorbitan monooleate, 2% soybean oil, 1% food grade paraffin oil, 1% batching (dibutyl 0.2% of hydroxytoluene, 0.2% of tert-butyl hydroxyanisole, 0.1% of propyl gallate, 0.1% of calcium sulfate, 0.2% of sodium polyphosphate, 0.2% of lactic acid) after mixing and stirring evenly, add to the aqueous solution containing 12% glycerin Stir evenly in medium, and disperse at a high speed for 5 minutes at 10000 rpm to obtain the emulsion lubricant according to the present invention. Among them, the viscosity of soybean oil mixed with food grade paraffin oil is 3.5 Pa.s, and the viscosity of the prepared lubricant is 0.05 Pa.s.

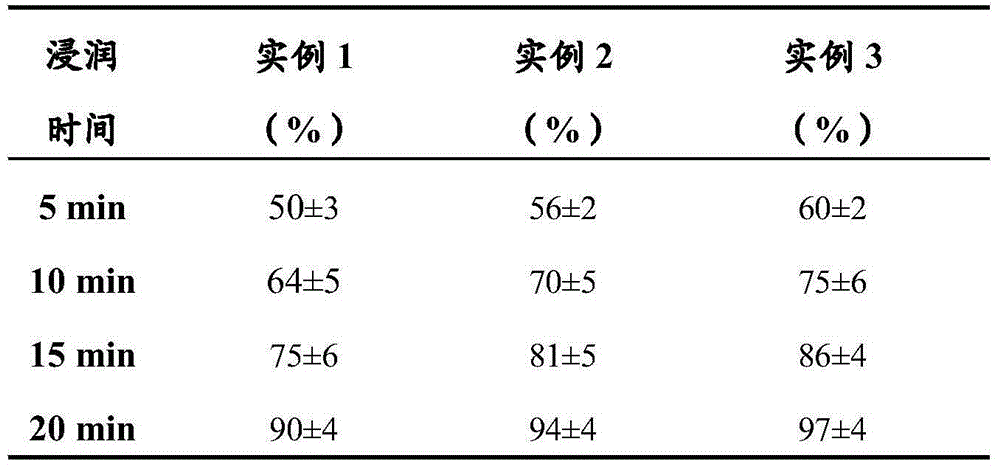

[0031] (2) Infiltration: After removing the content, flushing with water and soaking, infiltrate the pig original intestine with the lubricant prepared in step (1) for 10 minutes.

[0032] The breakage rate of pig casings has been reduced from the initial 10% to less than 1%.

Embodiment 2

[0034] (1) Preparation of lubricant: 4% sorbitan trioleate, 4% sorbitan monooleate, 2.5% corn oil, 0.5% food grade aromatic paraffin oil, 0.5% batching (dibutyl 0.2% of hydroxytoluene, 0.1% of propyl gallate, 0.1% of sodium polyphosphate, 0.1% of lactic acid) were mixed and stirred evenly, then added to the aqueous solution containing 15% glycerin and stirred evenly, and dispersed at a high speed of 10000rpm for 10min to obtain the present invention. lubricant, wherein the viscosity of corn oil mixed with food-grade aromatic oil is 2.5Pa.s, and the viscosity of the prepared lubricant is 0.04Pa.s.

[0035] (2) Soaking: After removing the content, flushing with water and soaking, soak the bovine gastritis with the lubricant prepared in step (1) for 15 minutes.

[0036] The breakage rate of cattle casings has been reduced from the initial 8% to less than 0.5%.

Embodiment 3

[0038] (1) Preparation of lubricant: with 5.6% sorbitan trioleate, 2.4% sorbitan monooleate, 1% lard, 2% food grade paraffin oil, 1% batching (dibutyl 0.2% hydroxytoluene, 0.2% tert-butyl hydroxyanisole, 0.1% propyl gallate, 0.1% calcium sulfate, 0.2% sodium carboxymethyl cellulose, 0.2% lactic acid) after mixing and stirring evenly, add to 8% glycerol Stir evenly in the aqueous solution of 10000rpm and disperse at a high speed for 5 minutes to obtain the emulsion type lubricant of the present invention. Among them, the viscosity of lard and food-grade paraffin oil is 6Pa.s after mixing, and the viscosity of the prepared lubricant is 0.09Pa.s.

[0039] (2) Infiltration: After removing the content, flushing with water and soaking, soak the sheep gastritis with the lubricant prepared in step (1) for 20 minutes.

[0040] The breakage rate of sheep casings has been reduced from the initial 15% to less than 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com