Method for weaving and processing polyester fiber elastic fabric for emplastrum

A polyester fiber and processing method technology, applied in the field of textiles and transdermal preparations, can solve the problems of unstable quality, easy impurities, untidy cloth surface, etc., and achieve simple processing methods, stable and reliable quality, and avoid matrix aging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The polyester fiber elastic cloth for plaster of the present invention is made of polyester fiber (PET / PBT / PTT) as a raw material, and the following process is used for weaving and preparation;

[0036] 1 Detection of polyester fiber (PET / PBT / PTT) elastic yarn: detect polyester fiber (PET / PBT / PTT) elastic yarn, determine where PET-polyethylene terephthalate (Polythylenerephthalate), PBT - The proportion of polybutylene terephthalate (polybutyleneterephthalate) and PTT-polytrimethylene-terephthalate (polytrimethylene-tereph-thalate) meets the requirements;

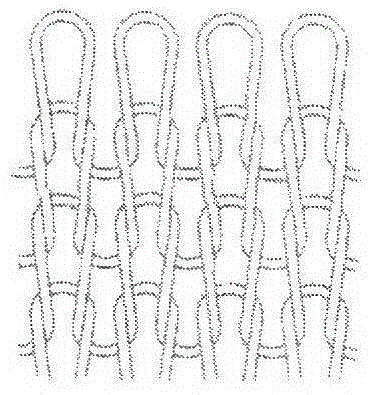

[0037] II Weaving: knitting a number of qualified weft yarns (elastic yarns) to form "flat stitch" or "Ω" shape, but not limited to elastic cloth with "flat stitch" texture, and ironing;

[0038] III Impurity removal: In the 100,000-class clean area, the woven elastic fabric is pulled through two vacuum cleaners with a power of 4kw and two suction heads, both of which are equipped with upper and lower suction heads, ...

Embodiment 2

[0045] Embodiment 2, basic technique is the same as embodiment 1, but sterilization temperature is 54~58 ℃, and sterilization time is 4 hours.

[0046] The relevant indicators of the polyester fiber elastic cloth for plasters obtained in Example 2 are: elongation 150%, elastic recovery rate 77%, loss on drying 0.30%, residue on ignition 0.53%, heavy metal≤10ppm, easy oxidation, pH value , non-volatile matter are in line with relevant regulations, formaldehyde content, 0.4ppm, ethylene oxide residue 0.157ug / cm2, total number of bacteria ≤ 4, total number of mold and yeast 0, the number of Pseudomonas aeruginosa is 0. The number of Staphylococcus aureus was 0.

Embodiment 3

[0047] Embodiment 3, basic technique is the same as embodiment 1, but sterilization temperature is 30~42 ℃, and sterilization time is 12 hours.

[0048] The relevant indicators of the polyester fiber elastic cloth for plasters obtained in Example 3 are: elongation 157%, elastic recovery rate 77%, loss on drying 0.32%, residue on ignition 0.56%, heavy metal≤10ppm, easy oxidation, pH value , Non-volatile matter all meet the relevant regulations, the formaldehyde content is 0.6ppm, the residual ethylene oxide is 0.159ug / cm2, the total number of bacteria is 10, the total number of mold and yeast is 0, and the number of Pseudomonas aeruginosa is 0. The number of Staphylococcus aureus was 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com