Combustion utilization method of low calorific value gas and combustion and hot air supply system

A technology of hot air supply and low calorific value, applied in combustion methods, gas fuel burners, burners, etc., can solve the problems of unfavorable use of metal partition wall heat exchangers, cost, high cost, complex structure, etc., to avoid heat energy loss and environmental pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

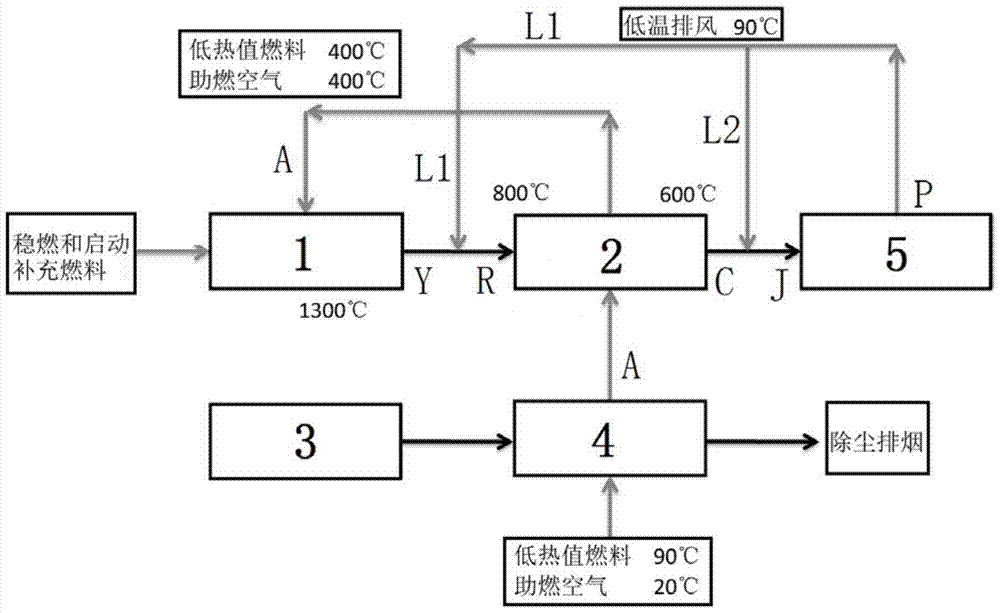

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0037] As mentioned above, in order to fully burn and utilize low-calorific-value gas and realize hot air supply, the present invention provides a combustion and utilization method of low-calorific-value gas. Those skilled in the art can understand that the "low calorific value gas" generally refers to all combustible gases with lower calorific value. For clarity, the calorific value range of the low calorific value gas defined in the following embodiments is 1.1-3.2 MJ / Kg.

[0038] see figure 1 , the combustion utilization method includes:

[0039] Preheating combustion step: low calorific value gas and combustion air are preheated by the preheater and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com