Method for continuously measuring contents of calcium and magnesium in silicon, calcium, barium and magnesium alloy

A determination method and technology of magnesium alloys are applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., which can solve the problems of waste of reagents, cumbersome operation and high cost, and improve production. Efficiency, shorten the operation process, reduce the effect of inspection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

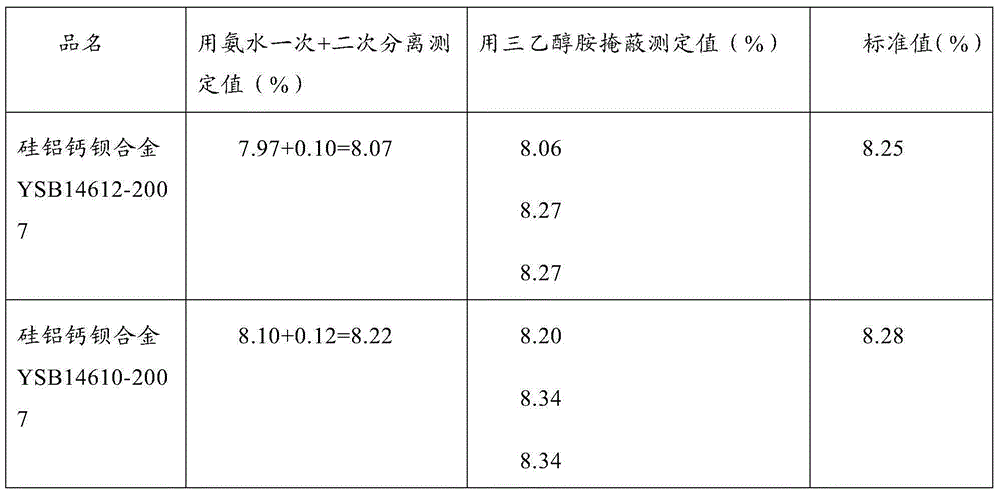

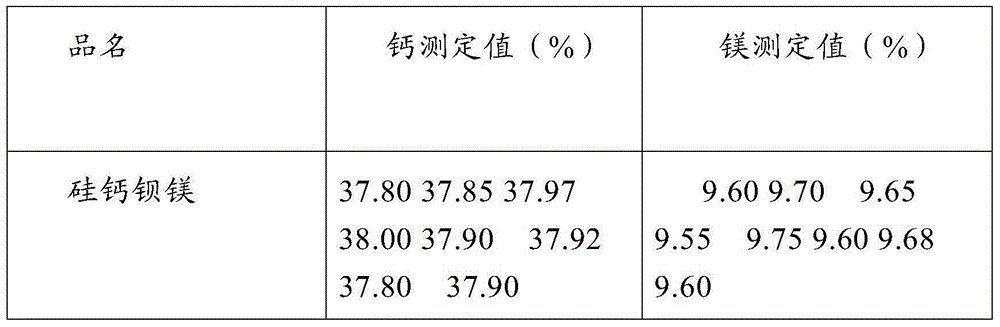

[0034] 1. Method summary: Dissolve the sample in a polyethylene plastic beaker with nitric acid (67%)-hydrofluoric acid (40%), add perchloric acid (70%) to emit smoke, the smoke is clear, and a little smoke cannot be seen. The liquid dries up. Add 10mL of hydrochloric acid (65%) and heat to dissolve the salts. Transfer the test solution to a 250mL volumetric flask and dilute to volume. Take two parts of 50mL solution, place them in two 250mL beakers respectively, add 50mL triethanolamine (12%) to one part, add 50mL water, add a little hydroxylamine hydrochloride, add 30mL potassium hydroxide solution (20%), keep the pH not low In 12), add an appropriate amount of calcein, titrate with EDTA standard solution until the fluorescent green disappears as the end point; add 50mL triethanolamine (12%), add 50mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com