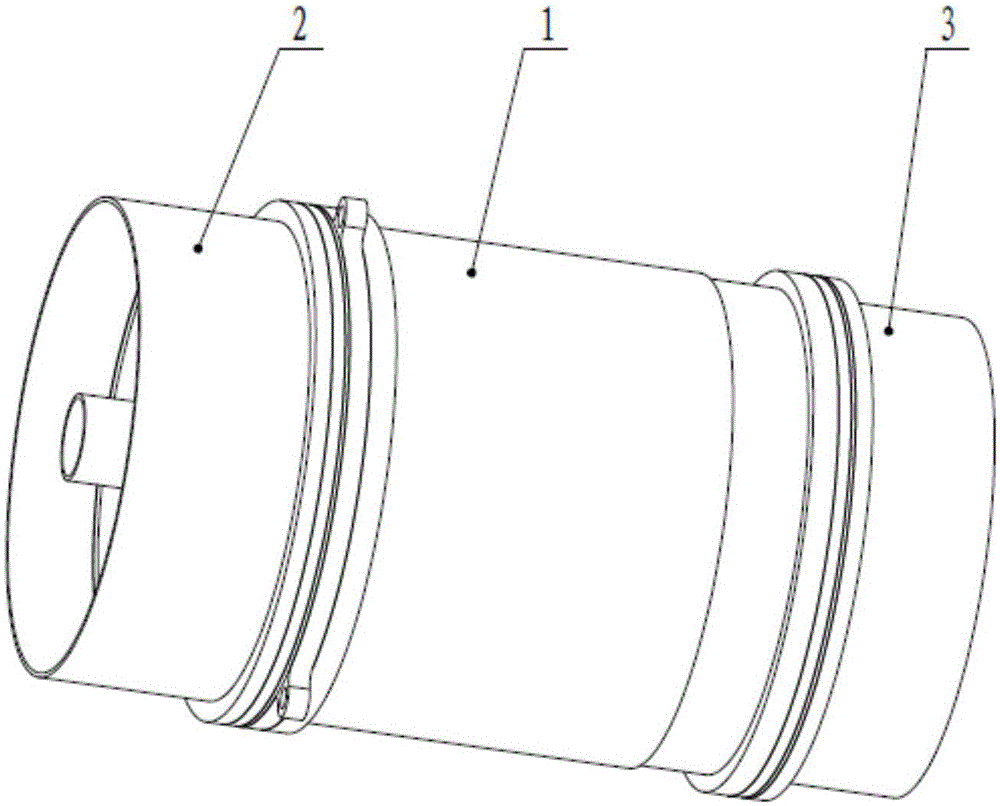

Multilayer nested conical surface type X-ray grazing incidence optical lens

An optical lens and X-ray technology, applied in the field of space optics, can solve the problems of the complex shape of the parabolic primary mirror and the hyperboloid secondary mirror, reduce the total reflectivity of the optical lens, and multiple noise floors, so as to increase the effective light collecting area. , The effective light collecting area is large, and the effect of reducing stray light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

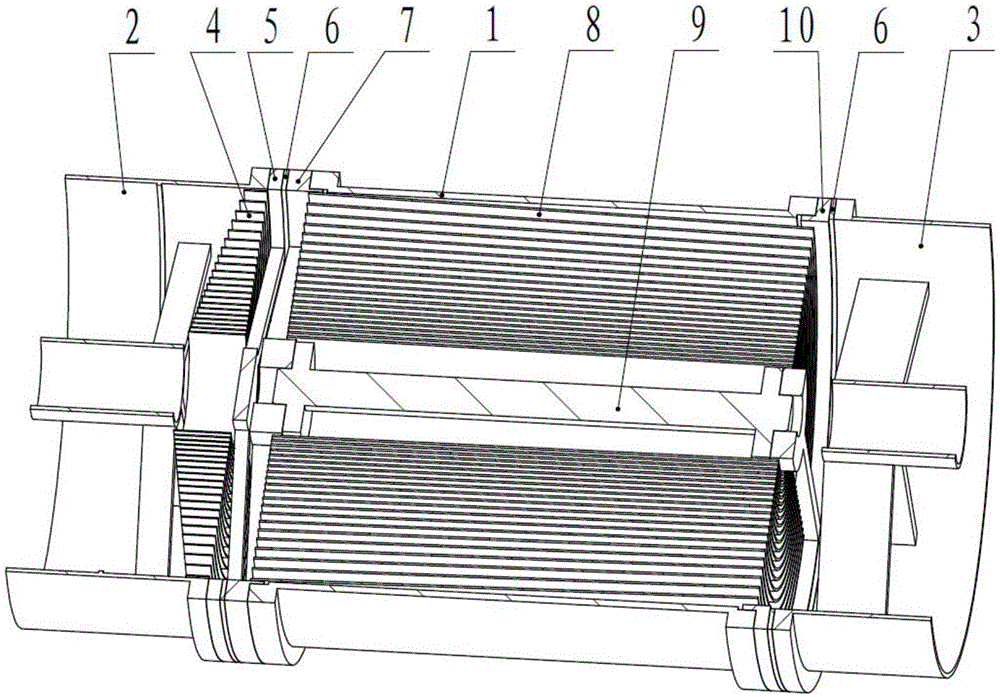

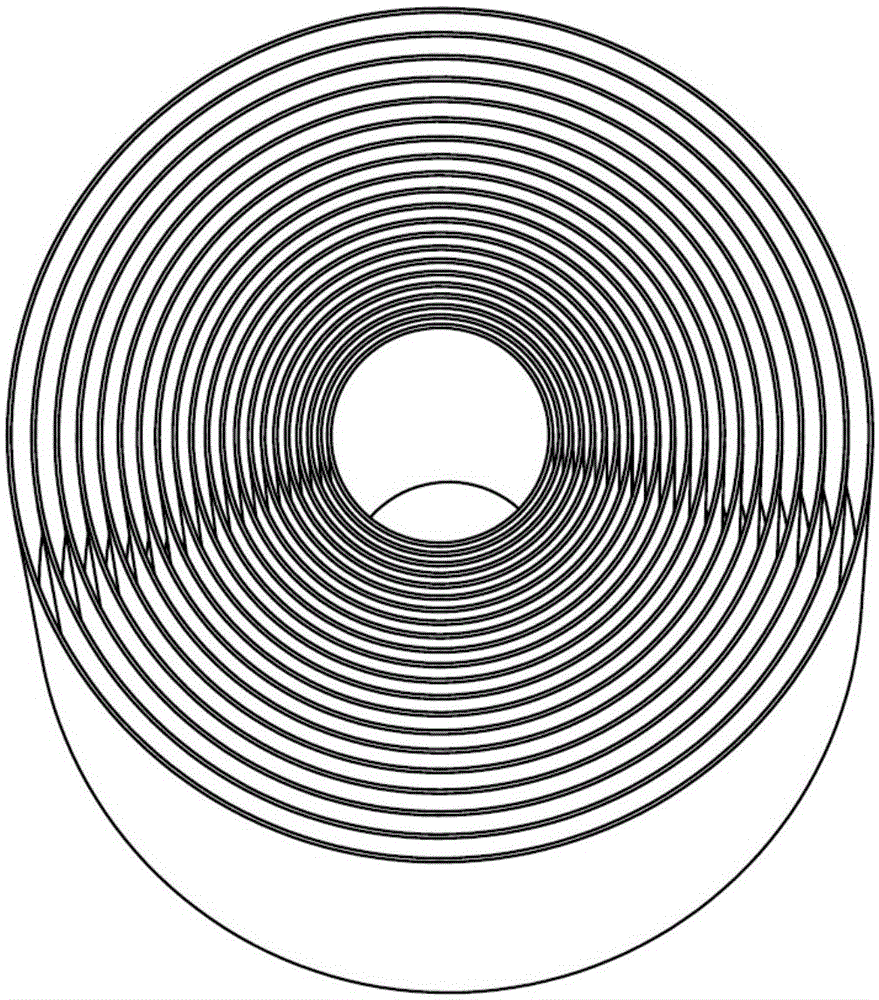

[0042] In this embodiment, in the multi-layer nested conical X-ray grazing incidence optical lens, the cone angle of the truncated cone of the lens in the lens layer 8 is 1° to 3°, and the cone angle gradually decreases from the outer layer to the inner layer. The thickness of the lens ranges from 0.2mm to 0.25mm, and the thickness of the outer layer gradually decreases from the outer layer to the inner layer to maintain basically the same ratio of lens thickness to lens diameter. The length of the lens is 110mm, the field of view is ±7.5arcmin, the focal length is 1200mm, and the number of nesting layers is 21. The diameter of the end of the outermost lens near the front spoke plate 7 is 107mm, and the diameter of the end of the outermost lens near the rear spoke plate 10 The diameter of the end of the innermost lens close to the front spoke plate 7 is 27.2mm, the diameter of the end of the innermost lens close to the rear spoke plate 10 is 26mm, and the surface roughness of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com