A kind of micro-methanol fuel cell based on magnesium alloy and its preparation method

A methanol fuel cell and magnesium alloy technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve problems such as poor corrosion resistance, large internal resistance of batteries, and poor thermal conductivity, so as to enhance corrosion resistance and improve Weight specific energy, effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

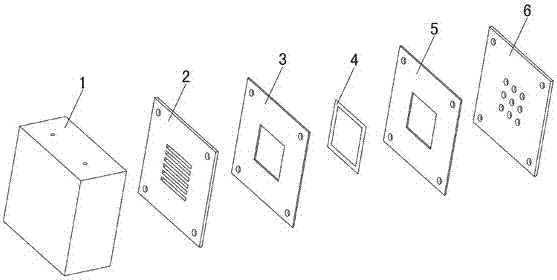

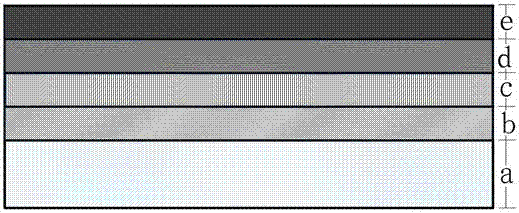

[0026] attached by figure 1 As shown: the micro-methanol fuel cell is composed of an anode liquid storage chamber 1, an anode flow field plate 2, an insulating pad 3, a membrane electrode 4, an insulating pad 5 and a cathode flow field plate 6. The anode liquid storage chamber 1, the anode The flow field plate 3 and the cathode flow field plate 6 are made of magnesium alloy material AZ91, and the surface of the magnesium alloy material is grown with alumina micro-arc oxidation porous ceramic film by micro-arc oxidation technology.

[0027] The preparation method of the miniature methanol fuel cell based on magnesium alloy, the method comprises the following steps:

[0028] ①. First make the anode liquid storage chamber with magnesium alloy AZ91 block material, then use 2mm thick AZ91 to make the cathode and anode flow field plates, and then separate the finished anode liquid storage chamber, cathode flow field plate and anode flow field plate Wash once with alcohol and deioni...

Embodiment 2

[0034] The difference between this embodiment and the foregoing embodiment 1 is that the electrolyte used in the micro-arc oxidation process contains 5-15 g / L of sodium phosphate and 1-5 g / L of potassium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com