Method for producing isocyanate

一种异氰酸酯、制造方法的技术,应用在异氰酸酯的制造领域,能够解决处理繁杂、毒性强等问题,达到回收容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

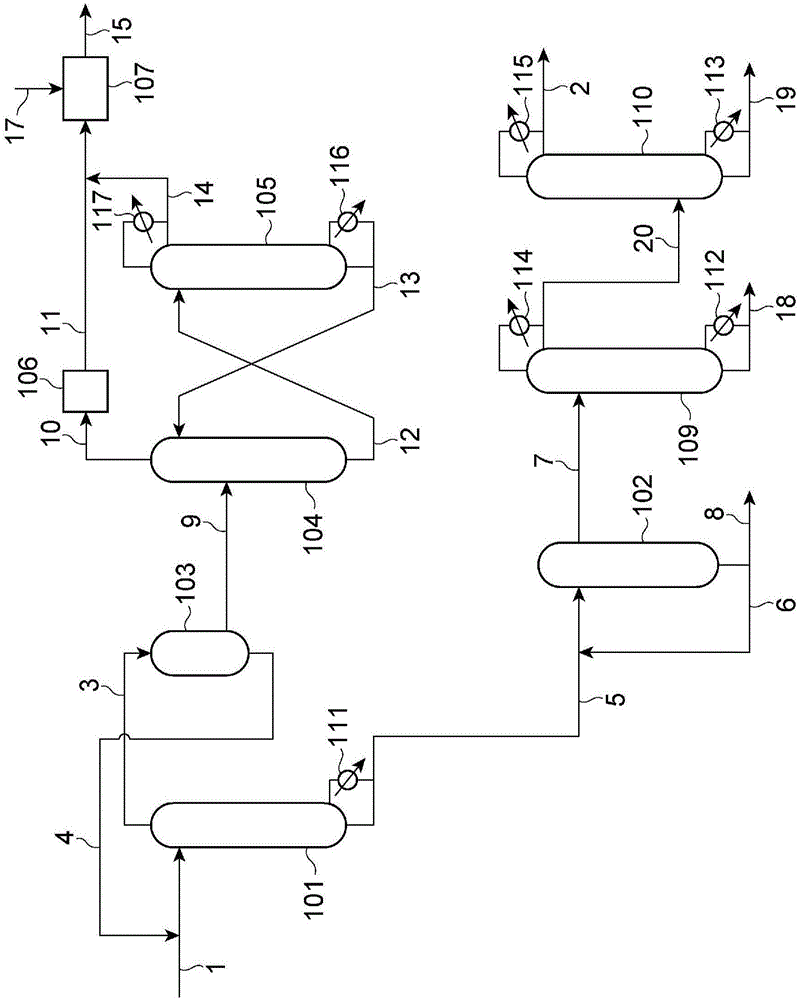

[0752] use figure 1 device shown. figure 1 The apparatus shown is an apparatus for performing a urethanization step, a step of separating a gas phase component mainly composed of ammonia, a step of manufacturing a gas-absorbing liquid, an ammonia separation step, a urea manufacturing step, and an isocyanate manufacturing step.

[0753] 7.2 kg of 1,6-hexamethylenediamine, 7.5 kg of urea (out of 7.5 kg of urea, 5.3 kg is urea produced by the urea production facility 107 described later), 4-(1,1,3, A mixture of 261.9 kg of 3-tetramethylbutyl)phenol was supplied to the continuous multi-stage distillation column 101 at about 92.2 kg / Hr. The liquid mixture of 4-(1,1,3,3-tetramethylbutyl)phenol and urea obtained in the condenser 103 was supplied from the line 4 at about 9.56 kg / Hr. The continuous multi-stage distillation column 101 is an apparatus for performing the urethanization step, and the temperature at the bottom of the column is 250° C. and the pressure at the top of the co...

Embodiment 2

[0758] (urethane process)

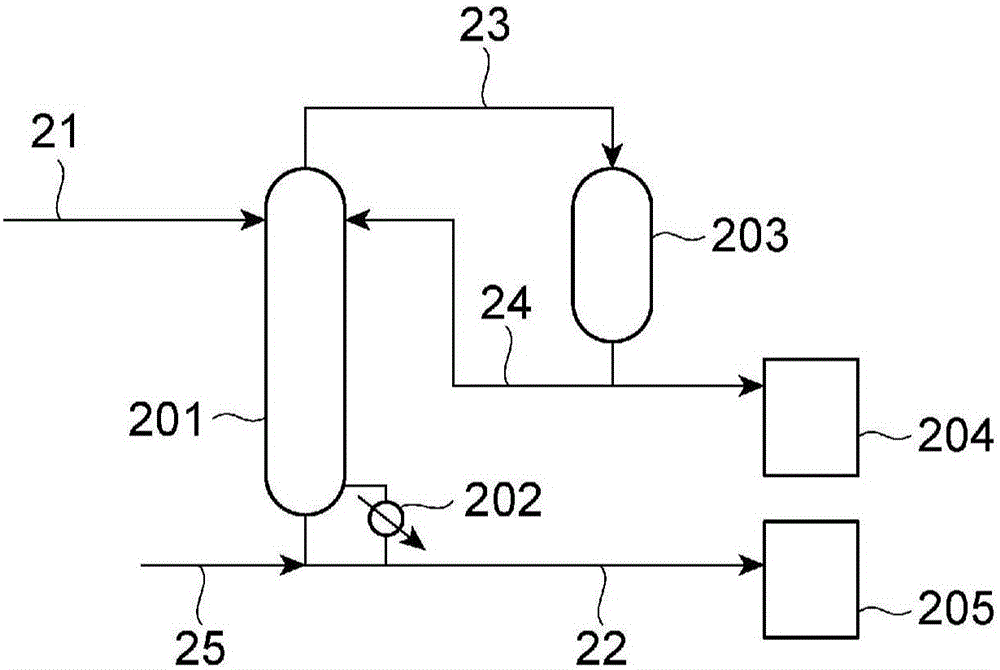

[0759] use figure 2The apparatus shown performs the urethanization process. A mixture of 11.3 kg of 1-amino-3-aminomethyl-3,5,5-trimethylcyclohexane, 15.1 kg of urea, and 220.3 kg of 1-butanol is supplied to the continuous multi-stage via line 21 at about 20 kg / Hr Distillation column 201. The mixed solution of 1-butanol and urea obtained in the condenser 203 was supplied from the line 24 at about 3.5 kg / Hr. The remaining condensed components are recovered to the storage tank 204 . The continuous multi-stage distillation column 201 is a device for performing the urethanization step, and the temperature at the bottom of the column is 220° C. and the pressure at the top of the column is 1.2 MPa by heating with the reboiler 202 . The reaction liquid is withdrawn from the bottom of the continuous multi-stage distillation column 201 and recovered to the storage tank 205 through the pipeline 22 .

[0760] (Preliminary Concentration Process)

[0761]...

Embodiment 3

[0772] (urethane process)

[0773] Use 4,4'-dicyclohexylmethanediamine 21kg instead of 1-amino-3-aminomethyl-3,5,5-trimethylcyclohexane, use urea 16.5kg, use 2,4-xylenol 250 kg was replaced with 1-butanol, and the method similar to the urethanization process of Example 2 was performed except having set the tower bottom temperature to 240 degreeC. From figure 2 The reaction liquid is extracted from the bottom of the continuous multi-stage distillation column 201, and is recovered to the storage tank 205 through the pipeline 22.

[0774] (Preliminary Concentration Process)

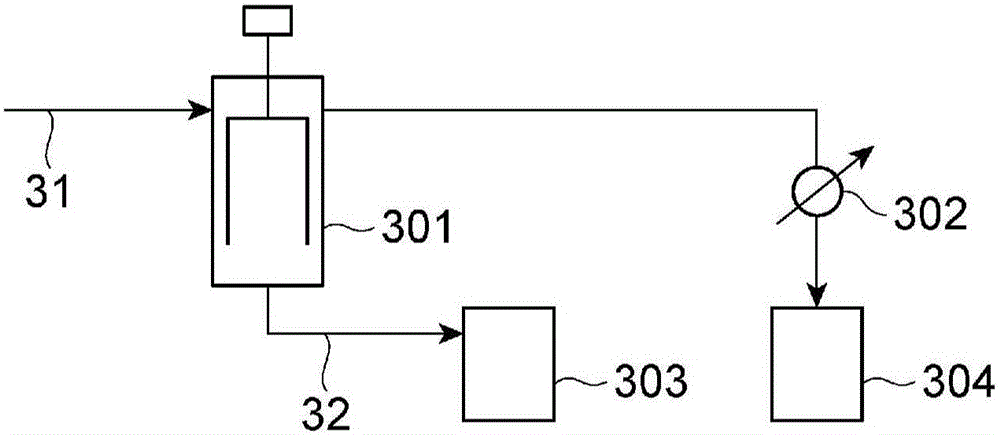

[0775] Make image 3 The jacket temperature of the thin-film evaporator 301 is 150°C, and the internal pressure is 10kPa. In addition, the same method as the preliminary concentration process of Example 2 is carried out, and the liquid is recovered from the bottom of the thin-film evaporator 301 at about 10kg / Hr. phase composition.

[0776] (Thermal decomposition process)

[0777] use Figure 4 The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| rate of recovery | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com