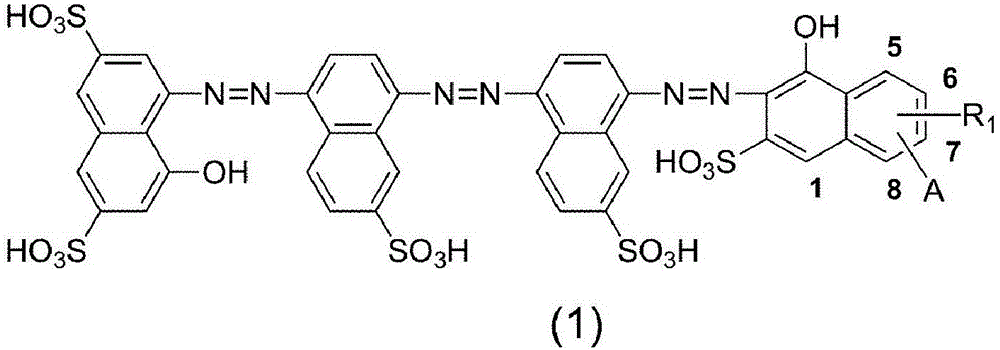

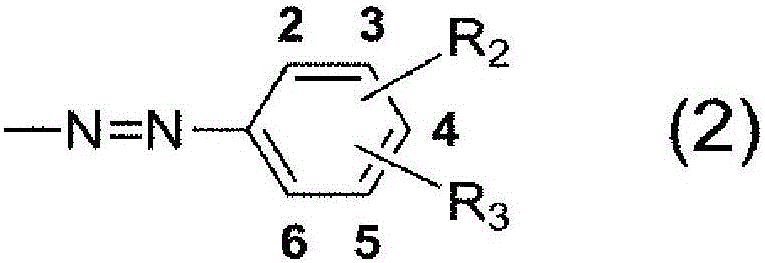

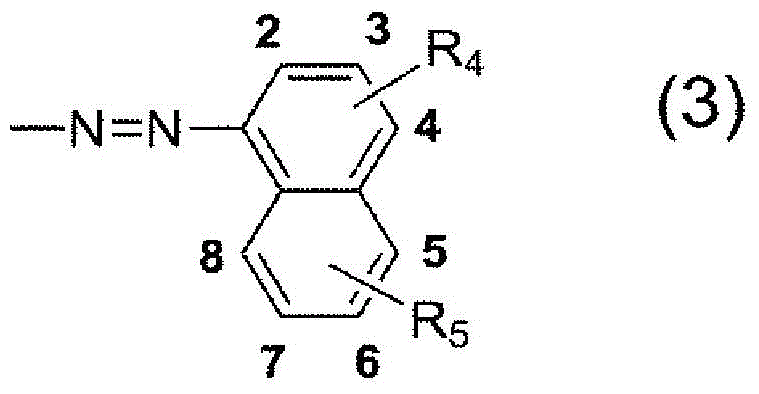

Tetrasazo compound for black, dye composition containing same, and dyeing method using same

A compound, tetrazo technology, applied in the field of dyeing products, can solve the problem of not finding dyes, etc., and achieve the effect of excellent light resistance and excellent dyeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] (Process 1)

[0074] [chemical formula 9]

[0075]

[0076] After adding 10 parts of 1-amino-8-(4-methylbenzenesulfonyloxy)naphthalene-3,6-disulfonic acid to 200 parts of water, drop 48% sodium hydroxide solution to adjust the pH to 6.0-7.0 and dissolve. 1.6 parts of sodium nitrite was added to the obtained solution, and it was added to the solution obtained by adding 8.8 parts of 35% hydrochloric acid to 90 parts of water at 10 to 15°C, stirred for 1 hour, and diazotized.

[0077] In 500 parts of water, 4.7 parts of 8-amino-2-naphthalenesulfonic acid was adjusted to pH 4.5-5.0 by 48% sodium hydroxide solution and dissolved, and the resulting diazotized The suspension was added dropwise over about 30 minutes. During the dropping, the pH of the reaction solution was maintained at 4.0 to 5.0 by adding an aqueous sodium carbonate solution. After completion of the dropwise addition, the mixture was stirred at 5 to 10° C. and pH 4.0 to 5.0 for 5 hours, and further sti...

Embodiment 2

[0097] (Process 1)

[0098] [chemical formula 14]

[0099]

[0100] After adding 3.5 parts of 8-amino-2-naphthalenesulfonic acid into 200 parts of water, 48% sodium hydroxide solution was added dropwise, adjusted to pH 6.0-7.0, and dissolved. 0.6 parts of sodium nitrite was added to the obtained solution, and this was added to the solution which added 2.8 parts of 35% hydrochloric acid to 90 parts of water at 10-15 degreeC, and it stirred for 1 hour, and diazotization was performed.

[0101] In 500 parts of water, 5 parts of 4-hydroxyl-7-phenylaminonaphthalene-2-sulfonic acid was adjusted to pH 4.5 to 5.0 by 48% sodium hydroxide solution and dissolved. After 60 minutes, the above diazotization reaction suspension was added dropwise. During the dropping, the pH of the reaction solution was maintained at 2.0 to 3.0 by adding an aqueous sodium carbonate solution. After completion of the dropping, the mixture was stirred at 5 to 10°C and pH 3.0 to 3.5 for 5 hours, and furthe...

Embodiment 3

[0111] 1.000 parts of the dyes synthesized in Examples 1 and 2 were dissolved in 1000 parts of water to prepare a dye bath, and 300 parts of kraft pulp (30 parts of absolute dry pulp, 35 SR of knock degree) were added to the dye bath, and stirred at room temperature After 15 minutes, 1 part of a 30% aqueous solution of rosin gum was added, and after further stirring for 10 minutes, 3 parts of crystalline aluminum sulfate were added and stirred for 20 minutes. Paper is made from the dyed pulp, and after drying, a black dyed product is obtained.

[0112] The resulting dyed matter was color-measured using COLOR EYE CE 3000 (manufactured by Macbeth Corporation) and visually, and judged by a colorimeter and by comparison of gray scales for discoloration and fading. In addition, the following light resistance test was performed. The results of the two tests are shown in Table 1.

[0113] The light resistance test method is as follows.

[0114] The dyed paper was irradiated for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com